I brewed another batch tonight. London porter. A bit less than 4 hours start to finish with a 2 hour mash. And I was doing other stuff half the time. OG was 1.060 with about 10.5 pounds of grain. I don't know for sure because I spilled some when milling and added to make it up.

Why 2 hour mashes ? Why not ? It runs almost unattended and I got busy doing other things, so I let it run. The conversion efficiency is crazy good.

I love brewing in the kitchen. I'm not 100% comfortable leaving it alone when it is running, so I can be near and yet do things like read or clean up.

I love that it is on wheels. I love working right in front of the sink when chilling and mashing in and yet you can roll it out of the way to do dishes, cook, etc. When you are in front of the sink you can use a spoon or remove a hose and put it right into the sink. Spray it with some water and it is clean 30 seconds after you use it.

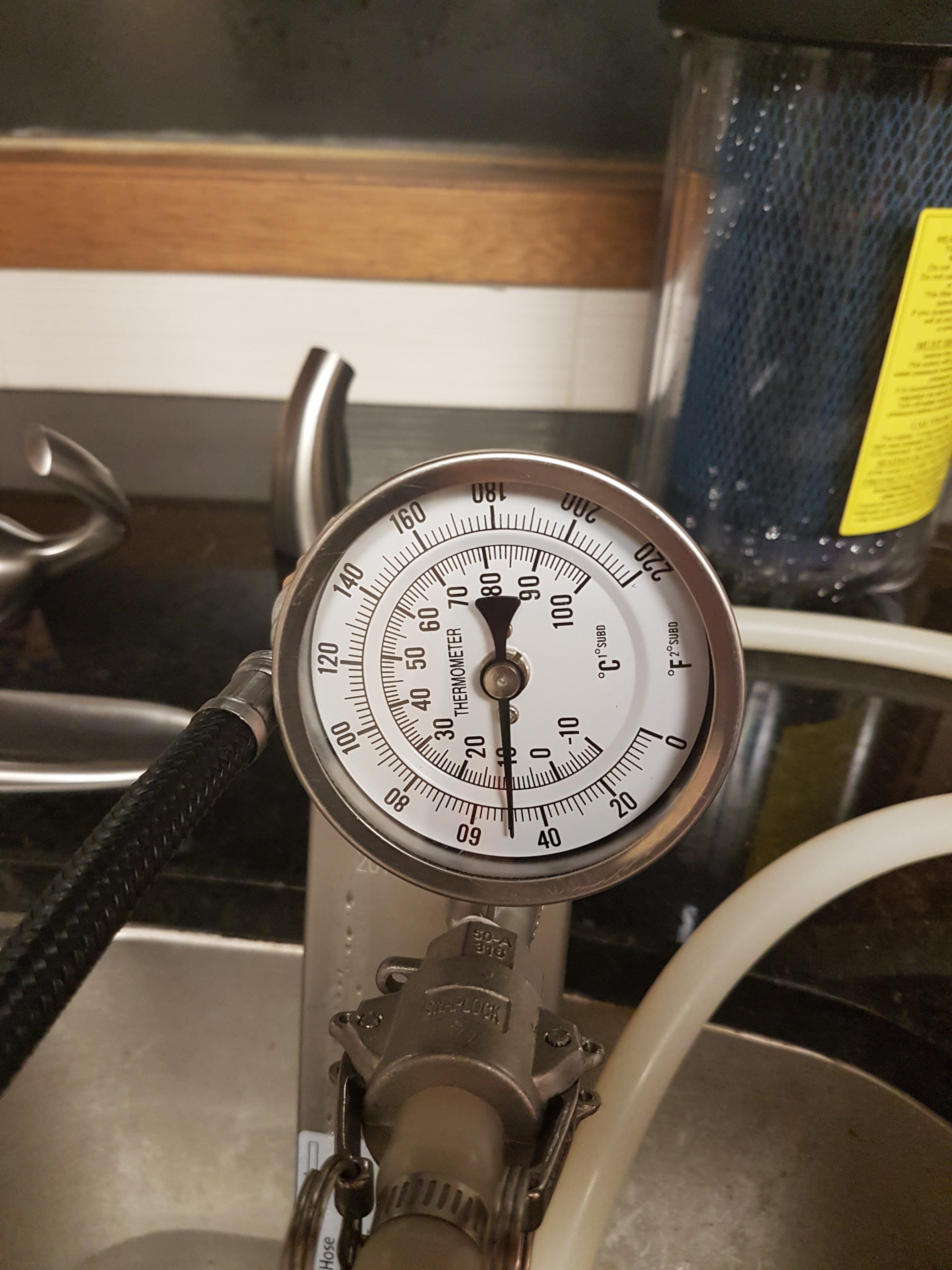

I still have a temp control issue to work on though. I need to change the temp sensors to something faster acting and read the return temp. The bed temp changes way too slow.

I'll be doing some other tweaks too.

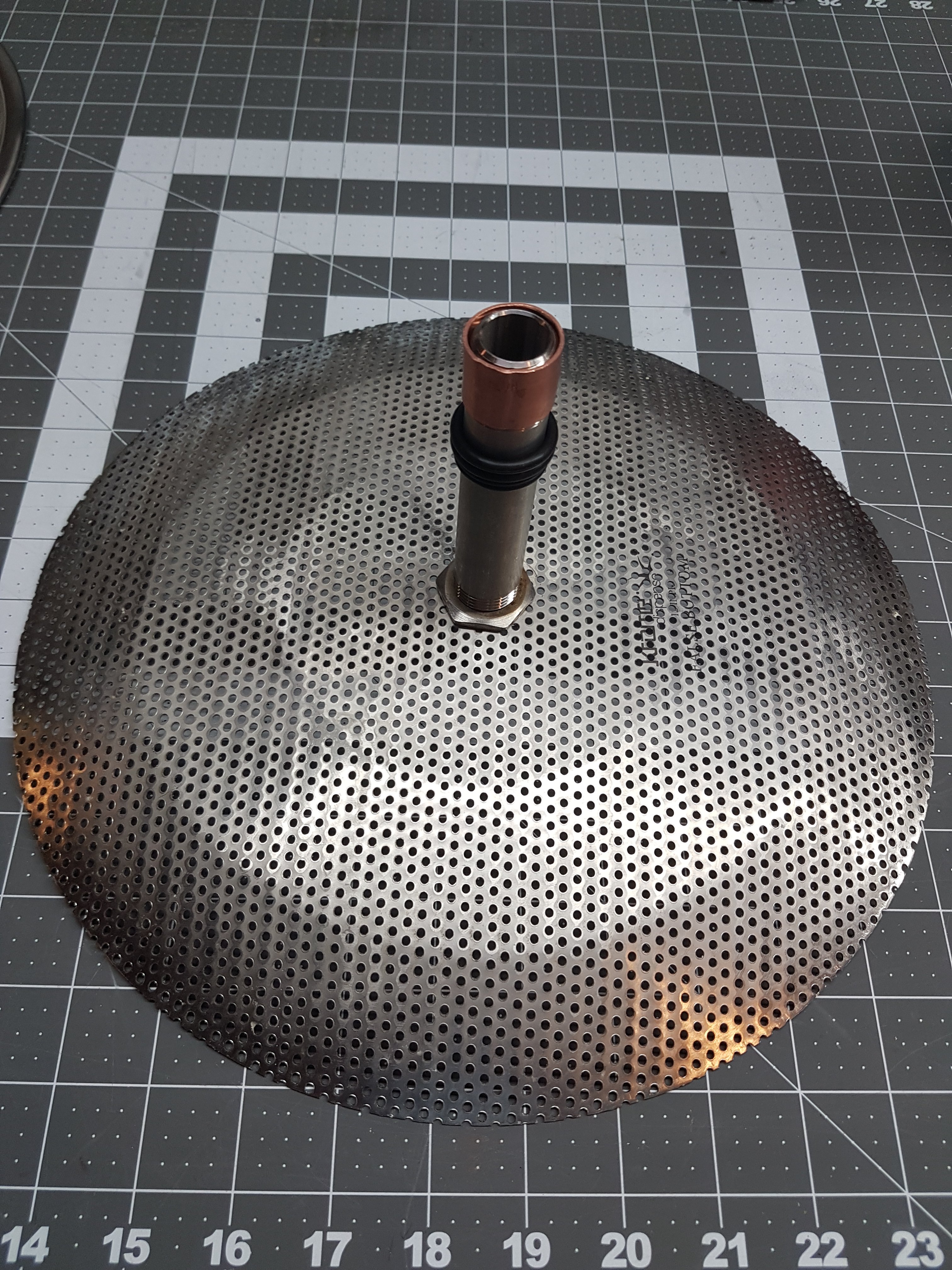

Mashing. The standpipe and strainer make things so easy. This batch had 20% wheat malt. I didn't use any rice hulls. No issues with stuck mash.

Typical boil. It has the perfect amount of power. Vigorous boil, but no boil over. It is close when it starts but after the foam dies a bit, it is good. I always boil open, no lid.

This is my post boil straining technique. First recirc the near boiling wort through the BIAB bag. Once all the grunge is filtered out, then recirc through the chiller to sterilize it. Then turn on the chilling water and recirc back into the kettle for a bit, filter out some cold break as well.

I ran without any hop filter in the kettle. No problems whatsoever. The kettle was almost perfectly clean at the end.

This is what the BIAB strainer catches. This batch only had 1 oz of hops. Most of that is hot and cold break.

Chilling worked great. I had total control of the outlet temp into the fermentor. I could drop it down further, but this is an ale that ferments at room temp.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)