I have a question about mashing... At least I think that’s the term for adding boiling the grain to pull sugars out. I hear you reach a temp, then add your grain, and then keep that temp for an hour. Now I read that you just wrap in a towel or something to hold that heat but it seems to me that this would make you loose some temp over the course of an hour. Should I keep testing the temp every few minutes? Than if it drops below my target temp, add some more heat from the stove for a minute or two to raise the temp again? Or is that a big no no?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Mashing

- Thread starter Shawnstve

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Dgallo

Instagram: bantam_brews

I wouldn’t check that often but def every 10 minutes if your mash turn isn’t insulated. If you do have to heat it again, just make sure you stir the grains while heating and don’t let the grain burn to the bottom of the pot.I have a question about mashing... At least I think that’s the term for adding boiling the grain to pull sugars out. I hear you reach a temp, then add your grain, and then keep that temp for an hour. Now I read that you just wrap in a towel or something to hold that heat but it seems to me that this would make you loose some temp over the course of an hour. Should I keep testing the temp every few minutes? Than if it drops below my target temp, add some more heat from the stove for a minute or two to raise the temp again? Or is that a big no no?

Ok thanks!!! Yeah 10 minutes sounds like a reasonable check time. How lax should I be with the temp? Like heat it if it drops 2 degrees? Or not till it drops 5 degrees? Also should I maybe start it at a degree higher or so to insure a longer time at target temp? Lol sorry I’m new to this.

coonmanx

Well-Known Member

I leave the pan on the stove but with the burner on the lowest setting. I check quite a few times during the initial 20 minutes but then less as the mash goes on. I also stir it from time to time. Temperature swings of a few degrees are not a big deal. Just try to keep it above 150 degrees and below 160 degrees and you should be fine. Also if you are using the appropriate amount of water to grain (1 gallon for every 3 pounds of grain) then you want to get the water to about 168 degrees before you mash in. That way it will be right about 155 after you have mashed in.

You can check for conversion at any time by getting a small amount of the wort (avoid picking up pieces of grain) and then putting that on a plate and adding a drop of iodine. If not converted the color will go black. If converted the color of the iodine will remain the same.

You can check for conversion at any time by getting a small amount of the wort (avoid picking up pieces of grain) and then putting that on a plate and adding a drop of iodine. If not converted the color will go black. If converted the color of the iodine will remain the same.

Dgallo

Instagram: bantam_brews

Now that’s a bigger question. Maintaining temperature is ideal even when step mashing. That being said, can you make a great beer if it fluctuates between 5 degrees over the mash? absolutely. As long as the mash stays above 146 and below 158 you will have fermentable beer. Now with that said, the temperature of the mash controls how dry or sweet the beer will finish and that’s why people target specific temps so they can dial in the way beer drinks. With you just learning a 2 degree sway in temp is fine so just try to stay within 2 degrees above or below of your intendedOk thanks!!! Yeah 10 minutes sounds like a reasonable check time. How lax should I be with the temp? Like heat it if it drops 2 degrees? Or not till it drops 5 degrees? Also should I maybe start it at a degree higher or so to insure a longer time at target temp? Lol sorry I’m new to this.

Last edited:

coonmanx

Well-Known Member

If you do decide to wrap it with something you might use a winter coat or something similar to hold in the heat. Maybe a thick blanket.

$172.35

2 Inch Tri Clamp Keg Manifold With Ball Lock Posts, Pressure Gauge, PRV (0-30 PSI) – Homebrew, Fermentation, Kegging System

wuhanshijiayangzhiyimaoyiyouxiangongsi

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$33.95

Five Star - 6022b_ - Star San - 32 Ounce - High Foaming Sanitizer

Bridgeview Beer and Wine Supply

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Gas MFL)

Guangshui Weilu You Trading Co., Ltd

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

coonmanx

Well-Known Member

From the book "Brewing Quality Beers" by Byron Burch....

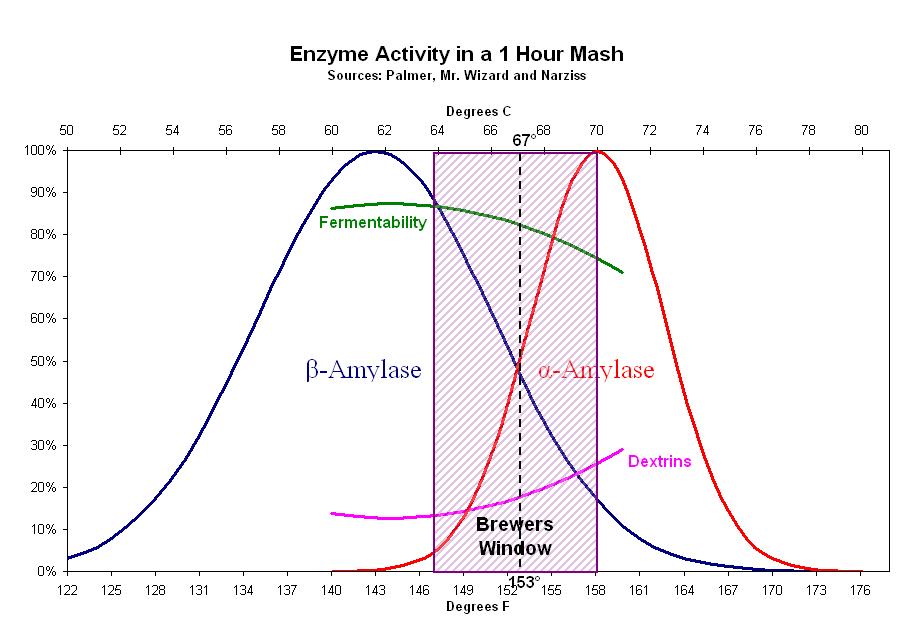

The enzymes which convert starches all the way to fermentable sugars become active as soon as the temperature reaches 125 degrees or so, and their activity is most intense between 140 degrees and 149 degrees....

The dextrin producing enzymes (dextrines give you mouthfeel) are most active between 150 degrees and 158 degrees.

What this all means is that you can change your beer just by changing the temperature of the mash. A beer made from a 155-158 degree mash will have a fuller mouthfeel, with slightly more sweetness and less alcohol than an identical beer mashed at 148 degrees....

So this is why I generally shoot for a mash temp of 155 degrees. I don't always stay perfectly on that temp but I do get close and make adjustments when necessary. The important thing is the first thirty minutes or so when there is maximum enzyme activity and also it is important to not get too hot where the enzymes would quit working completely. I do always test with iodine just to make sure that I have converted all starches to sugars. Just remember that on intial mash in you want the temperature to be about 13 degrees above the target temperature because if you are using that 3 pounds of grain to one gallon of water ratio that should get you right to where you want to be after adding in the grain. Also stir that grain in well when adding and make sure there are no lumps.

I do also raise the temperature to close to 170 degrees right before sparging. The idea with that is that the sugars will be easier to release off of the grains at the higher temperature. My sparge water is at 170 degrees as well. Of course do the temperature raise after you are certain that all starches have been converted to sugars.

The enzymes which convert starches all the way to fermentable sugars become active as soon as the temperature reaches 125 degrees or so, and their activity is most intense between 140 degrees and 149 degrees....

The dextrin producing enzymes (dextrines give you mouthfeel) are most active between 150 degrees and 158 degrees.

What this all means is that you can change your beer just by changing the temperature of the mash. A beer made from a 155-158 degree mash will have a fuller mouthfeel, with slightly more sweetness and less alcohol than an identical beer mashed at 148 degrees....

So this is why I generally shoot for a mash temp of 155 degrees. I don't always stay perfectly on that temp but I do get close and make adjustments when necessary. The important thing is the first thirty minutes or so when there is maximum enzyme activity and also it is important to not get too hot where the enzymes would quit working completely. I do always test with iodine just to make sure that I have converted all starches to sugars. Just remember that on intial mash in you want the temperature to be about 13 degrees above the target temperature because if you are using that 3 pounds of grain to one gallon of water ratio that should get you right to where you want to be after adding in the grain. Also stir that grain in well when adding and make sure there are no lumps.

I do also raise the temperature to close to 170 degrees right before sparging. The idea with that is that the sugars will be easier to release off of the grains at the higher temperature. My sparge water is at 170 degrees as well. Of course do the temperature raise after you are certain that all starches have been converted to sugars.

Last edited:

Nubiwan

Well-Known Member

- Joined

- Dec 1, 2018

- Messages

- 584

- Reaction score

- 365

From the book "Brewing Quality Beers" by Byron Burch....

The enzymes which convert starches all the way to fermentable sugars become active as soon as the temperature reaches 125 degrees or so, and their activity is most intense between 140 degrees and 149 degrees....

The dextrin producing enzymes (dextrines give you mouthfeel) are most active between 150 degrees and 158 degrees.

What this all means is that you can change your beer just by changing the temperature of the mash. A beer made from a 155-158 degree mash will have a fuller mouthfeel, with slightly more sweetness and less alcohol than an identical beer mashed at 148 degrees....

So this is why I generally shoot for a mash temp of 155 degrees. I don't always stay perfectly on that temp but I do get close and make adjustments when necessary. The important thing is the first thirty minutes or so when there is maximum enzyme activity and also it is important to not get too hot where the enzymes would quit working completely. I do always test with iodine just to make sure that I have converted all starches to sugars. Just remember that on intial mash in you want the temperature to be about 13 degrees above the target temperature because if you are using that 3 pounds of grain to one gallon of water ratio that should get you right to where you want to be after adding in the grain. Also stir that grain in well when adding and make sure there are no lumps.

I do also raise the temperature to close to 170 degrees right before sparging. The idea with that is that the sugars will be easier to release off of the grains at the higher temperature. My sparge water is at 170 degrees as well. Of course do the temperature raise after you are certain that all starches have been converted to sugars.

With this in mind, and taking into consideration the attached Alpha/Beta chart, will it make a whole lot of difference if my MASH temp fluctuates 5-10 degrees between 158 and 148 over an hour? It seems people on here drum into everyone about keeping mash temps constant.

I ask this because I am going to be brewing outdoors for the foreseeable future, and maintaining a steady mash temp in 10 degree Celsius 50 F garage, is going to be a minor challenge. Even if I do use sleeping bags etc.

Is it fair to assume efficiency is determined (or dictated by) by the SG of your pre-boil mash? That if you are maintaining a lower mash temp, therefore creating those more fermentable sugars, you are achieving a potentially higher ABV, and therefore higher efficiency?

If my last statement is true, then why not let my mash cover a wider temperatures to satisfy both Alpha and Beta activities? Why attempt to keep it constant?

With this in mind, and taking into consideration the attached Alpha/Beta chart, will it make a whole lot of difference if my MASH temp fluctuates 5-10 degrees between 158 and 148 over an hour? It seems people on here drum into everyone about keeping mash temps constant.

The question isn't what the difference will be over the hour long mash but how long will it take for you to get full conversion? Does it take an hour? 90 minutes? 2 hours? Maybe the conversion is done in less than an hour? Mine is. Way less than an hour. How do I achieve that? By using the BIAB system and milling the grain fine enough that it gelatinizes the starches quickly. Once the starch is gelatinized, conversion is very quick.

If your mash starts at 158 and conversion is quick, you get mostly unfermentable sugars (maybe). Once the starches are converted the enzymes are quickly denatured (destroyed). Will you have enough surviving beta amylase to convert the unfermentable sugars (dextrines) or will it all be denatured at the higher temperature?

With my very fine milling of the grain it doesn't seem to matter much whether I mash at 152 or 158, I seem to get the same fermentability of the wort. Why?

Velnerj

Simul justus et potator

Will your pot

Will your pot fit in your oven? Preheat to 155 set it and forget it...Thanks guys for the reply. Ok so it sounds like I wanna try to be within a couple degrees of the recommended for a specific recipe. Ok will do! Thanks!

Preheat, check temp, and TURN OFF!Will your pot

Will your pot fit in your oven? Preheat to 155 set it and forget it...

Oven thermostats are notoriously inaccurate, and slow to react. Don't cook your mash!

You may want to check halfway through and add a little heat if needed. Again, don't forget to turn it off.

Similar threads

- Replies

- 28

- Views

- 2K

- Replies

- 10

- Views

- 2K

Latest posts

-

-

-

Canned wort: concentrate vs non-concentrate; hot break material

- Latest: EscapeArtistBrewing

-

-

-