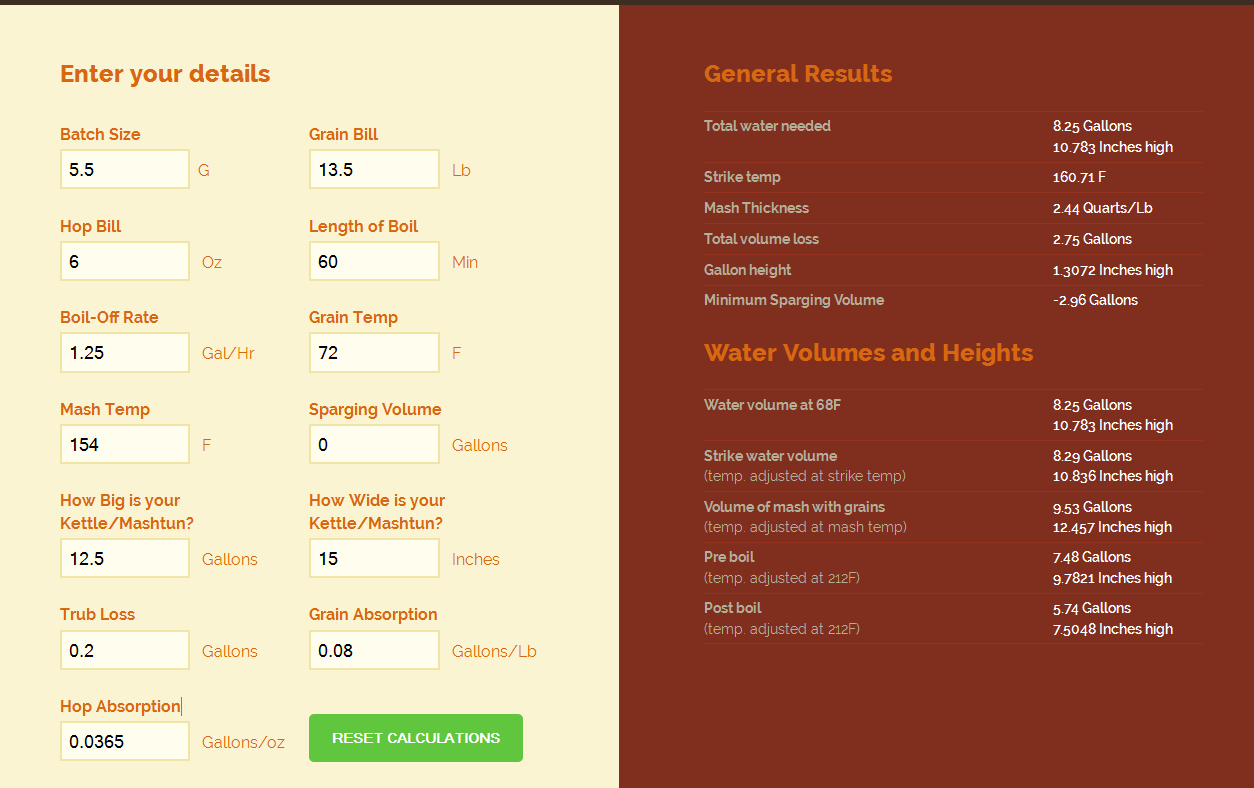

Priceless, out of curiosity, what parameters cause the mash thickness of you calculator to change? For this past brew it called for 2.44 qts per lb. At 13.5 lbs. My next brew will be 10 lbs, calling for 3.19 qts per lb. Same amount of hops.

In short: Mash volume and grain bill.

In Long: Grain bill dictates some of the total water needed, which affects how much mash volume will fit in the pot, which affects how much you might have to sparge.

Grain bill. More grains means more water absorbed.

If you sparge or not, and how much. More you sparge, the thicker the mash.

Grain absorption.

Higher absorption means more water is lost, so mash is thinner.

Batch Size More beer means more water.

Boil off rate

Hop bill, and hop absorption. Since they'll absorp some wort in the boil.

Trub loss between kettle and primary.

Only thing that doesn't affect it in some way is the temps lol.

Strictly the mash thickness is = Strike volume * 4 / Gbill.

The 4 is because mash thickness is in quarts, but volumes are in gallons.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)