is there any granularity on the actual time and temp of denaturing Alpha amylase an Beta amylase? A few questions to focus my query:

1. Are both enzymes denatured at the same temp range? If not, what is the temp range for each?

2. How long does denaturing take? Is the time related to temperature?

4. Does the Alpha(higher temp) active range denature Beta?

4. Does the action of Alpha prepare the starches to be more readily converted by Beta, or could a mash schedule focusing on optimizing beta only result in a thorough ferment?

These are great questions. Frankly I cannot provide specific answers, so I will continue to instead answer in a more general and figurative manner:

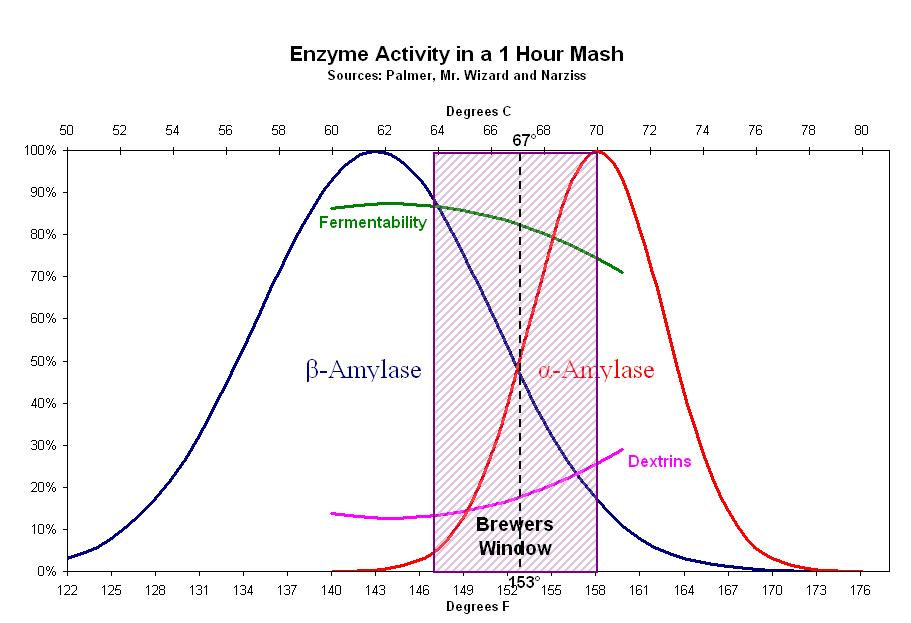

I like to imagine the beta and alpha amylase as different kinds of machines. They each function in quite a different manner, but each have a speed dial which is temperature. Now imagine thousands of each type of machine running all together at the same time and the same temperature. Since there is only one control knob for all of them, the betas will always be running a lot faster than the alphas so they'll tend to wear out much quicker. As we turn the dial higher (temperature), both types of machines run faster and faster at breaking down starches in different ways, until at some point they get old and fail. However, since there are thousands of each, some will fail early, and some will hang on for much longer before they fail, sort of a random bell curve on each (as you see pictured above!). The beta machine is a really effective one, might even be our favorite; however, it's also much more fragile and will tend to break quicker (i.e., at more moderate temperatures). The alpha machine meanwhile is generally much more robust, but also doesn't always give us exactly the results we want either if all the beta were to fail early. So, what we really want is for both types of machines to both work together, the alpha product constantly being refined by the beta, without breaking the beta too quickly by running it too fast, but also not turning the knob too far left keeping the alpha from helping out as much. A happy medium is generally desired.

Both beta and alpha are constantly being denatured at any warm temperature, but beta will always be running much harder and wearing out quicker at any given temperature, because the alpha just happens to be built stronger. Some alpha will fail at lower temperatures, but generally most alpha will hang on for a longer time than beta. And at relatively high temperatures, most of the beta is certain to fail pretty quickly (I'm not exactly sure how long, could be 5 minutes, 10, 15, 20, somewhere around there, but depending on exactly how hot for how long -- yeah there must be data out there but personally I don't know it).

If we select a mash favoring the alpha alone, or especially near the high end for the alpha, then the beta will still provide assistance, but most will denature in a very short time (probably a few minutes like I said above).

I think if you had a sufficiently long mash time (several hours) for either the low end for beta or the high end for alpha, the exact temperatures and enzymes involved become less and less important. If you mashed say for 8-10 hours like an overnight mash, if the temperature was very low, the beta could do a nice job for you unless it denatures eventually anyway, but the alpha will chug along slowly even at lower temperatures and just chew right through everything given enough time I think. Meanwhile we do need to take care not to take the mash too hot say at 165-168 F where the alpha might become denatured too quickly leaving us with a dextrinous mess that is not very fermentable even if left to mash for hours on end. But any lower than that, say at 160-162 F, I think enough alpha will survive to make a highly fermentable wort, at least until such time that it too all denatures.

Wish I had better specifics, but regardless, I hope perhaps this discussion will help somebody understand the workings of these little machines a little better. Bottom line: At low temperature, they don't denature much and just chug along slowly, but given enough time (many hours) will still do a very nice job for us. At high temps, alpha probably can do a reasonably good job, maybe even great, if they don't denature too fast. And anywhere in between, that's just Goldilocks, keep it there for as short or as long a time as you like really, the longer you keep it there the more fermentable the wort will become.

Finally I should add: In my opinion, mash TIME seems to be FAR more important than specific mash temperature, as long as we keep the mash temperature anywhere within the Goldilocks zone. If I want a fuller bodied beer, personally I mash for a shorter TIME, say only 35-40 minutes, at any reasonable temperature. And personally if I want a very dry beer, then I'll mash not just at 147 F for 60 minutes, but go 90 minutes or even 120 minutes or more, then it will turn out very dry indeed. And even if I were to mash warmer at say 155 F or something like that, I'll bet after 90-120 minutes, I'll still get a very dry beer indeed because the alpha will be working so fast, chainsawing the bajeezus out of the starches and dextrins for a nice long time.

Not sure if this helps a lot, but there you have it, for whatever it's worth. Cheers all.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)