LandoLando

Member

- Joined

- Apr 15, 2017

- Messages

- 7

- Reaction score

- 2

Hi, this is my second post. The first post was apparently in the wrong sub forum. I've been brewing for about 5 years now. I'm a process engineer so it follows that I am curse with an insatiable desire for process control.

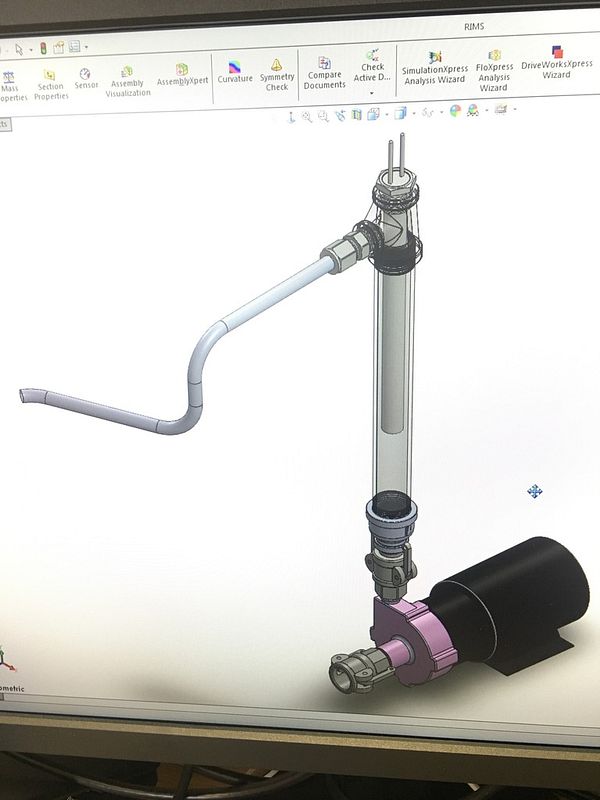

I have a 14 gallon kettle with a valve on the bottom. I also have a 10000 BTU/hr heating element from a hot tub. I want to install the heating element inline with a Brau inline pump and control the temp with a thermistor, 50A solid state relay, and Arduino microcontroller. The plan is to bring the mash water within 5 F of mash temp with my burner, and then run the pump and heater to control the temp. Add the grain once the mash water is at the appropriate temp and let her rip.

Any concerns?

Are the Bräu pumps quality?

If i have a constant whirlpool can i trust that the temp is uniform throughout the mash?

Any one do multiple step infusions with a similar setup?

I have a 14 gallon kettle with a valve on the bottom. I also have a 10000 BTU/hr heating element from a hot tub. I want to install the heating element inline with a Brau inline pump and control the temp with a thermistor, 50A solid state relay, and Arduino microcontroller. The plan is to bring the mash water within 5 F of mash temp with my burner, and then run the pump and heater to control the temp. Add the grain once the mash water is at the appropriate temp and let her rip.

Any concerns?

Are the Bräu pumps quality?

If i have a constant whirlpool can i trust that the temp is uniform throughout the mash?

Any one do multiple step infusions with a similar setup?