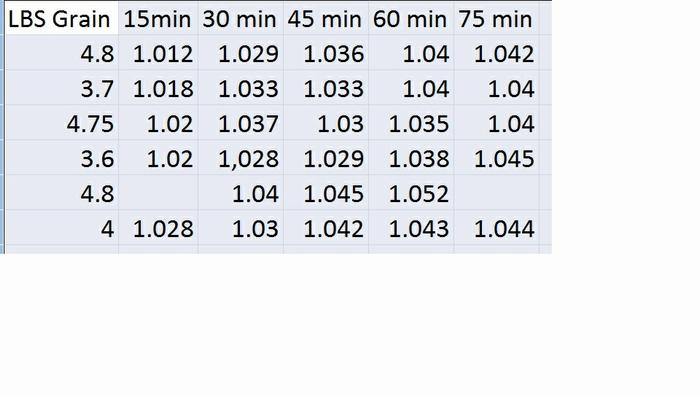

I keep seeing recurring comments about Mash Time, and responses about how conversion is done in far less than the hour of mashing, and you can mash for xx minutes and be done. If this was the case, why does everyone do a 1 hour (or more) mash?

Correct me if I'm confused here, but isn't this sort of a 2 step process - converting starches to unfermentable sugar, then breaking down those sugars to fermentable states, where this sugar conversion is directly related to mash temperature, and time.

Every time I see a comment about conversion being done in minutes I cringe, based on my understanding of the process. Yeah, you'll get beer, but is it the beer you were expecting?

Can the 'experts' weight in?

Correct me if I'm confused here, but isn't this sort of a 2 step process - converting starches to unfermentable sugar, then breaking down those sugars to fermentable states, where this sugar conversion is directly related to mash temperature, and time.

Every time I see a comment about conversion being done in minutes I cringe, based on my understanding of the process. Yeah, you'll get beer, but is it the beer you were expecting?

Can the 'experts' weight in?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)