MrSaLTy

Well-Known Member

Awesome. Ladder, is that 1/2 inch copper? and also what diameter holes did you drill? So doing this.

Was this the 1-1/4" FIPS x 1" Slip adapter ($1.60 ea) you were looking for?revco said:This is super easy if you have the pump. Here's what you'll need: (1) 1-1/4" Lead Free Brass or SS Coupler (1) 1-1/4" to 1" Lead Free Brass or SS Reducer Bushing (1) 1" MIPS to Slip CPVC Adapter (Note, the three above parts can be replaced if you can find a CPVC 1-1/4" FIPS x 1" Slip Adapter, I haven't found any personally.

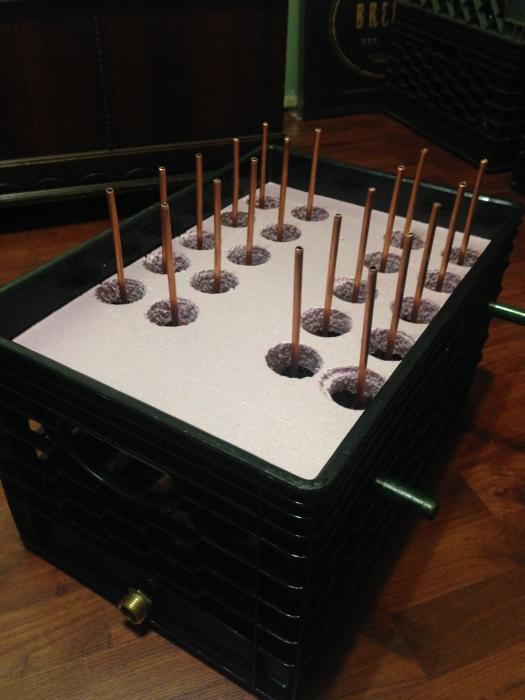

So I was able to make this finally and it works great!

I followed Nameless's version of this bottle washer as I use the fastrack. I must say it makes this process even easier when you use the fastrack. I did not make posts like you design did but surprisingly enough the posts are not necessary. water still makes contact with the bottom of the bottle at all times. I used the same pump that you recommended and instead of placing the bottles inside the crate, I put them on top of the crate to elevate them.

I cut notches into the fastrack feet so the rack literally just fits into place and does not move. It only takes a few minutes and all 24 bottles are fresh and clean!

Thanks for the great ideas, Ill post later if I have any updates.

I cycle from Oxyclean to clean water to StarSan.

Hey man, I just built this unit but out of PVC. What size holes did you use in your copper?

Where is everyone getting the cross cpvc fitting?? I can find the pvc cross fitting all day no problem, but not cpvc.

I've had a few people ask me this, so I think you're not alone. Unfortunately, I don't have a lot of insight to offer. I got all my parts at a very small neighborhood hardware store in upper-Manhattan.