o0_Enigma_0o

Active Member

Good Morning Guys.

Just wondering if you could help choosing what to build a mash tun from.

I have a couple of options but not sure what the best route would be and I would prefer not to buy any more containers if possible.

Using an old but small cool box (Maybe 20L - Its so far in my garage I cannot reach it)

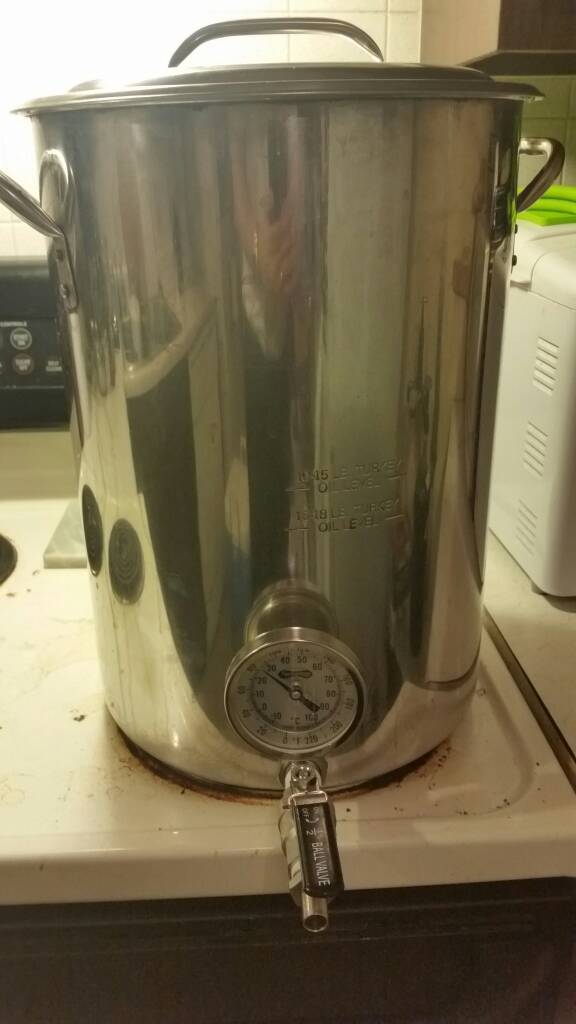

Using a 5 gallon steel kettle (huge sauce pan)

Using a beer Keg I have acquired from my local pub

I have lots of pipe fixing, stainless steel filters(bazooka screens), stainless taps etc

What do you guys think the best container would be to convert into a mash tun?

would I get benefits by using a smaller container and then using a Sparging system?

My current thoughts are to use foil insulation (looks like foil bubble wrap) to insulate the 5 gallon steel kettle. But not sure if it will hold temperature long enough.

Many thanks in advance for any help you can provide.

Just wondering if you could help choosing what to build a mash tun from.

I have a couple of options but not sure what the best route would be and I would prefer not to buy any more containers if possible.

Using an old but small cool box (Maybe 20L - Its so far in my garage I cannot reach it)

Using a 5 gallon steel kettle (huge sauce pan)

Using a beer Keg I have acquired from my local pub

I have lots of pipe fixing, stainless steel filters(bazooka screens), stainless taps etc

What do you guys think the best container would be to convert into a mash tun?

would I get benefits by using a smaller container and then using a Sparging system?

My current thoughts are to use foil insulation (looks like foil bubble wrap) to insulate the 5 gallon steel kettle. But not sure if it will hold temperature long enough.

Many thanks in advance for any help you can provide.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)