You are probably aware that many of us are following your adventure with great interest.

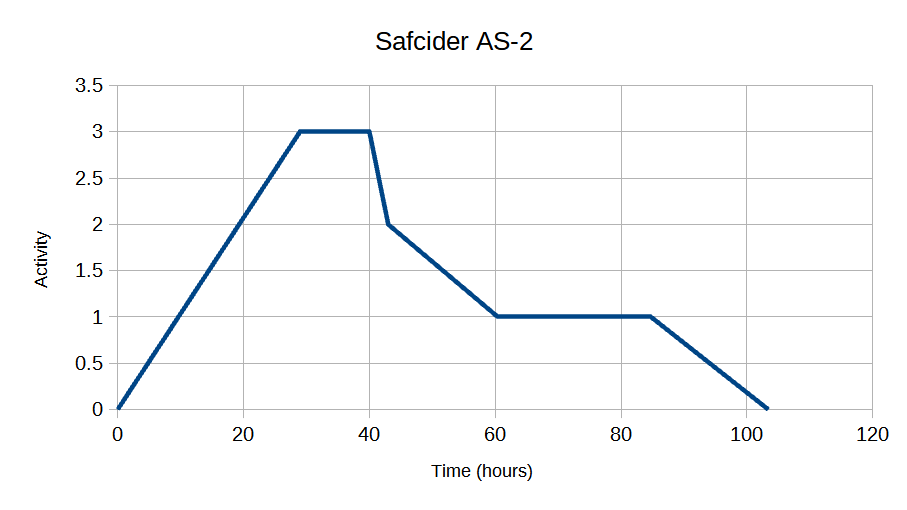

I am intrigued that you rate AC4 as a winner and AB1 as a loser since the Fermentis profiles seem similar and I would have expected the results to be similar. Please tell us more. FYI, in case you haven't seen it, I attached a paper covering these yeasts to Madscientist451's post of last Saturday. This was written by Fermentis' Technical Manager, Fruit Fermentation, and although probably originally in French and translated into English, it is "followable".

Please keep reporting about what is happening because I would like to try these new yeasts and value your input.

I am intrigued that you rate AC4 as a winner and AB1 as a loser since the Fermentis profiles seem similar and I would have expected the results to be similar. Please tell us more. FYI, in case you haven't seen it, I attached a paper covering these yeasts to Madscientist451's post of last Saturday. This was written by Fermentis' Technical Manager, Fruit Fermentation, and although probably originally in French and translated into English, it is "followable".

Please keep reporting about what is happening because I would like to try these new yeasts and value your input.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)