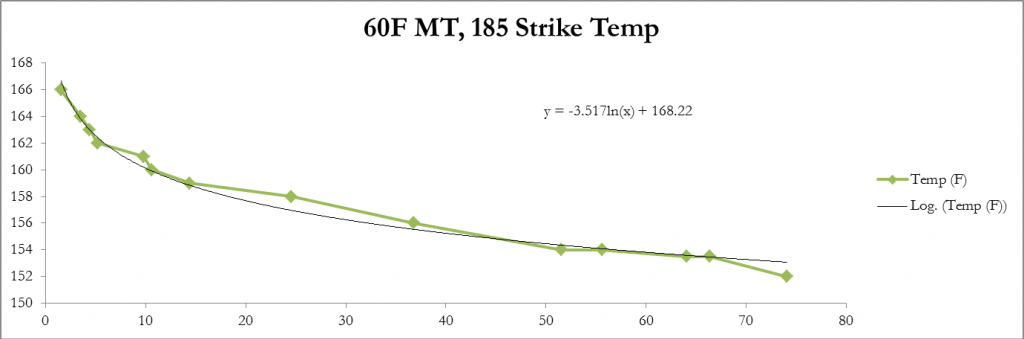

I did a test with my mash tun today using only water to see how well it would retain heat. I had heating issues using it for my first all grain batch. Temps dropped too low.

I did a test with a little over 3 gallons. My "strike" temp was 170F. I did not preheat the Lowes circular style cooler.

I closed the lid when it was 165F. In one hour the temp went from 165F down to 153F. Again using only water. Clearly not good.

Now the most obvious question is, does the lack of grain in the cooler speed the drop in temp? I assume the grain itself would help act as insulation and help retain that heat. But by how much?

If not, not sure what else I can do. I did not cover it with a blanket. That might help a couple degrees. The outside weather here today is fine, 68F. I've read people have tried to insulate the lid with spray foam insulation. Maybe I can try that.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)