I poked around the forms a bit and could not find an answer to this question.

I have my electric brewery up and running. On my first brew day, all went well except I am getting a serious amount of condensation in my condensate hood.

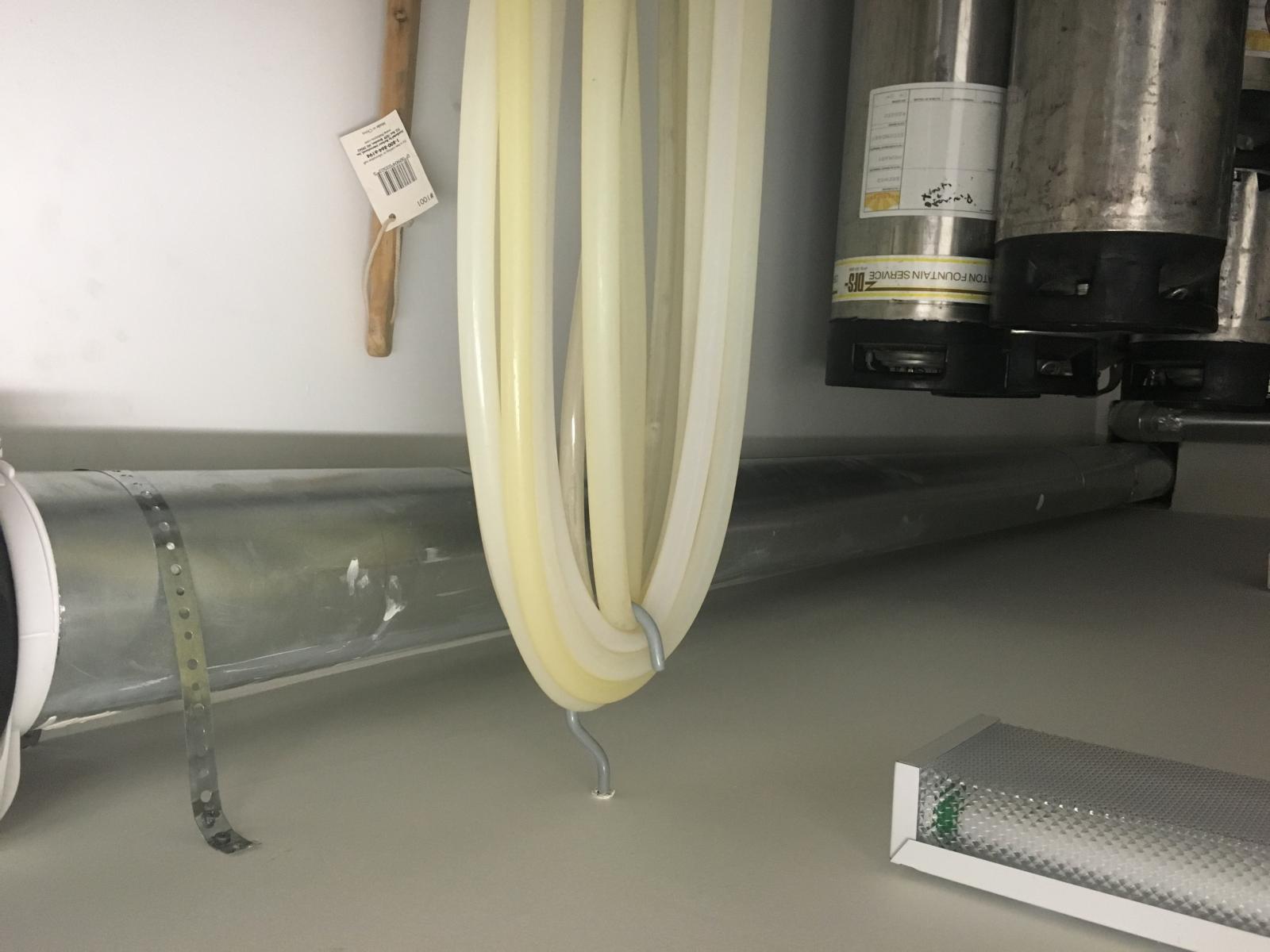

The hood is 5' long x 2' wide x 1' tall. It is 2 ft. from the top of my pots. I have 6" ducting setup. There hole in the hood is centered in the top and there are two 90 degree elbows to get the exhaust to fun to my duct run. The overall length of run is 25 feet. I am using a 347 CFM 6" inline fan.

I am guessing that the 347 CFM is not sufficient for removing all of the steam, but I'm trying to figure out what CFM I need to prevent the excessive condensation and/or if there is anything else I should be doing in order to help prevent this excessive condensation.

Lastly, does anyone know if I add another fan in line with the current fan, will that boost the overall ability to remove the steam? or is the CFM not additive?

The only fans I can find with a high CFM are larger diameter, so I'm wondering if I should install reducers in the duct line (6"->10") and install a 10" fan in a small section of the duct run?

Any advice is greatly appreciated!

I have my electric brewery up and running. On my first brew day, all went well except I am getting a serious amount of condensation in my condensate hood.

The hood is 5' long x 2' wide x 1' tall. It is 2 ft. from the top of my pots. I have 6" ducting setup. There hole in the hood is centered in the top and there are two 90 degree elbows to get the exhaust to fun to my duct run. The overall length of run is 25 feet. I am using a 347 CFM 6" inline fan.

I am guessing that the 347 CFM is not sufficient for removing all of the steam, but I'm trying to figure out what CFM I need to prevent the excessive condensation and/or if there is anything else I should be doing in order to help prevent this excessive condensation.

Lastly, does anyone know if I add another fan in line with the current fan, will that boost the overall ability to remove the steam? or is the CFM not additive?

The only fans I can find with a high CFM are larger diameter, so I'm wondering if I should install reducers in the duct line (6"->10") and install a 10" fan in a small section of the duct run?

Any advice is greatly appreciated!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)