cantrell00

Well-Known Member

- Joined

- Jul 6, 2013

- Messages

- 840

- Reaction score

- 116

I generally don't recommend that people do that.

As you work down a side. This allows an electrician to put in single pole, single unit width breakers down each side distributing the load as he goes or to install a two pole double width breaker in two slots for 240 V circuits.

That's what I would expect but you would need the voltmeter to verify.

Again I don't recommend that people fiddle in their panels unless qualified or unless under the supervision of a qualified person but yes, a qualified person could swap wires and labels between an adjacent pair of single width breakers and so swap the phases to which they are attached.

You'd have to move two wires. It may actually be easier to just swap the positions of the breakers.

No but the question again arises as to what to do with the two outlets on opposing phases. No doubt that would allow you to construct 240 V circuits in your garage. The question is as to how to do it safely. There are devices that one can buy that can be plugged into two opposite phases outlets that have a 240 V receptacle on the female end. Are these UL approved? I have no idea. What would your insurance company have to say if there were an electrical fire, even one unrelated to these circuits, and they found this stuff in the ashes? Again I don't know and wouldn't want to undertake such a project until I had consulted someone who did.

The appeal of using a pair of 4500 W 240 heaters is clearly great but connecting them to a single circuit, even with an interlock, violates the letter (we could argue about the spirit but how would we do in this argument if it were with an insurance adjuster?) of Secs 210, 220 and 384 of the NEC which state that a breaker must be sized to 100% of the current demand of all intermittent loads on the circuit. One of the most appealing aspects is that one could, with a little additional circuitry (a pair of diodes and switches/contactors) arrange to have either on at full power or both on at half power (2250 W) and still draw less than 20 amps.

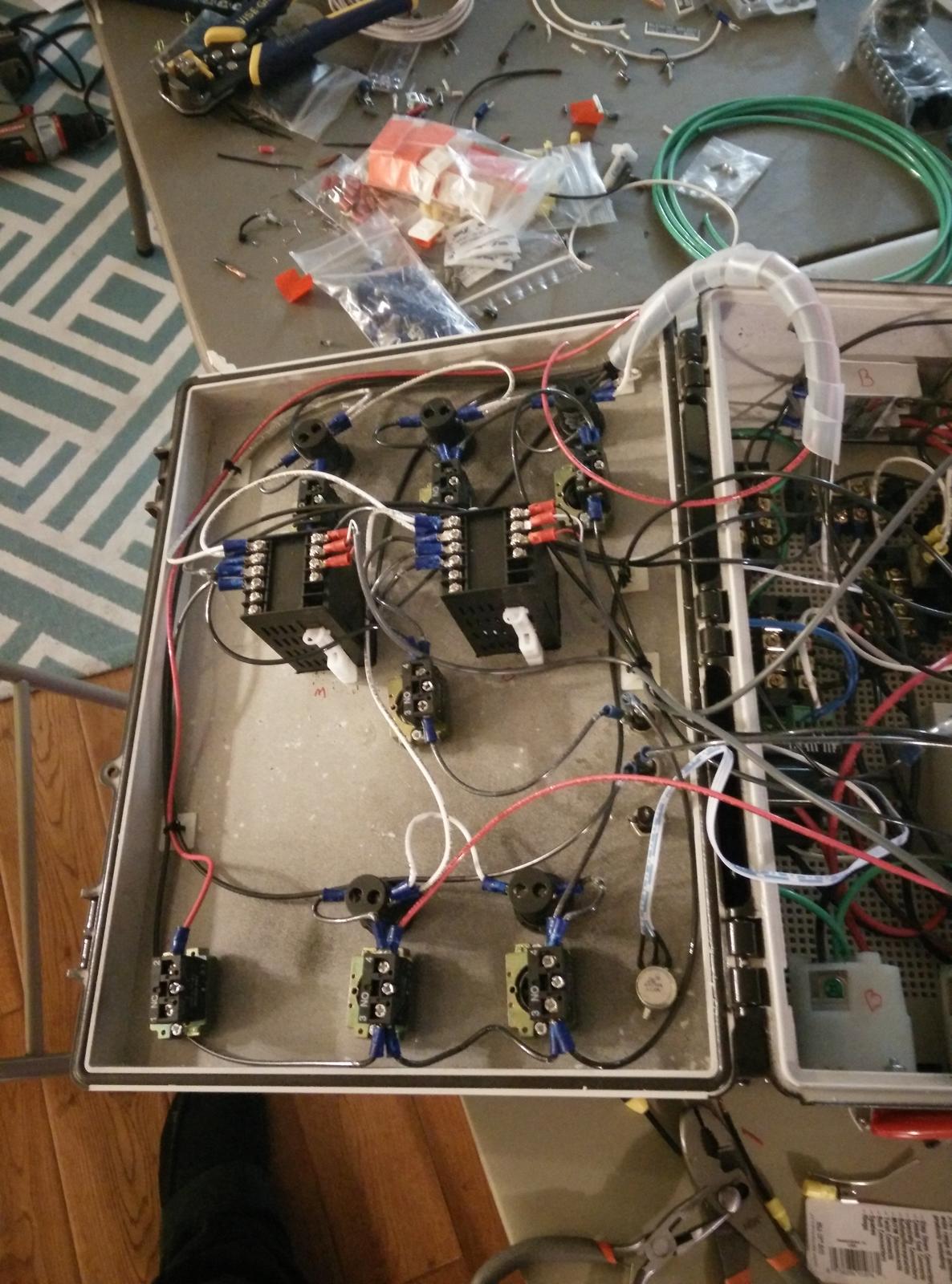

I follow... These two receptacles will require a drop from each receptacle to my controller box... So the only time it would be ran this way is when I would be brewing.

And just to clarify, combining the two 120 outlets would result in a single 20A/4500V element, not two.

Thanks a ton for taking the time to write all of this in such detail.

I will consult with my electrician friend and have him make the modifications assuming I choose to go that route.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)