blasterooni

PIpe line is now well established

I have been listening to podcasts and watching videos talking about Kveik strains, however, at best there is a but a slight mention of cider while the rest of the talk is about beer. How do I approach using Kveik strains with cider? Do I go with the beer approach and bottle or keg when the cider reaches the desired FG? Do I age it? Bottle age or leave it the carboy?

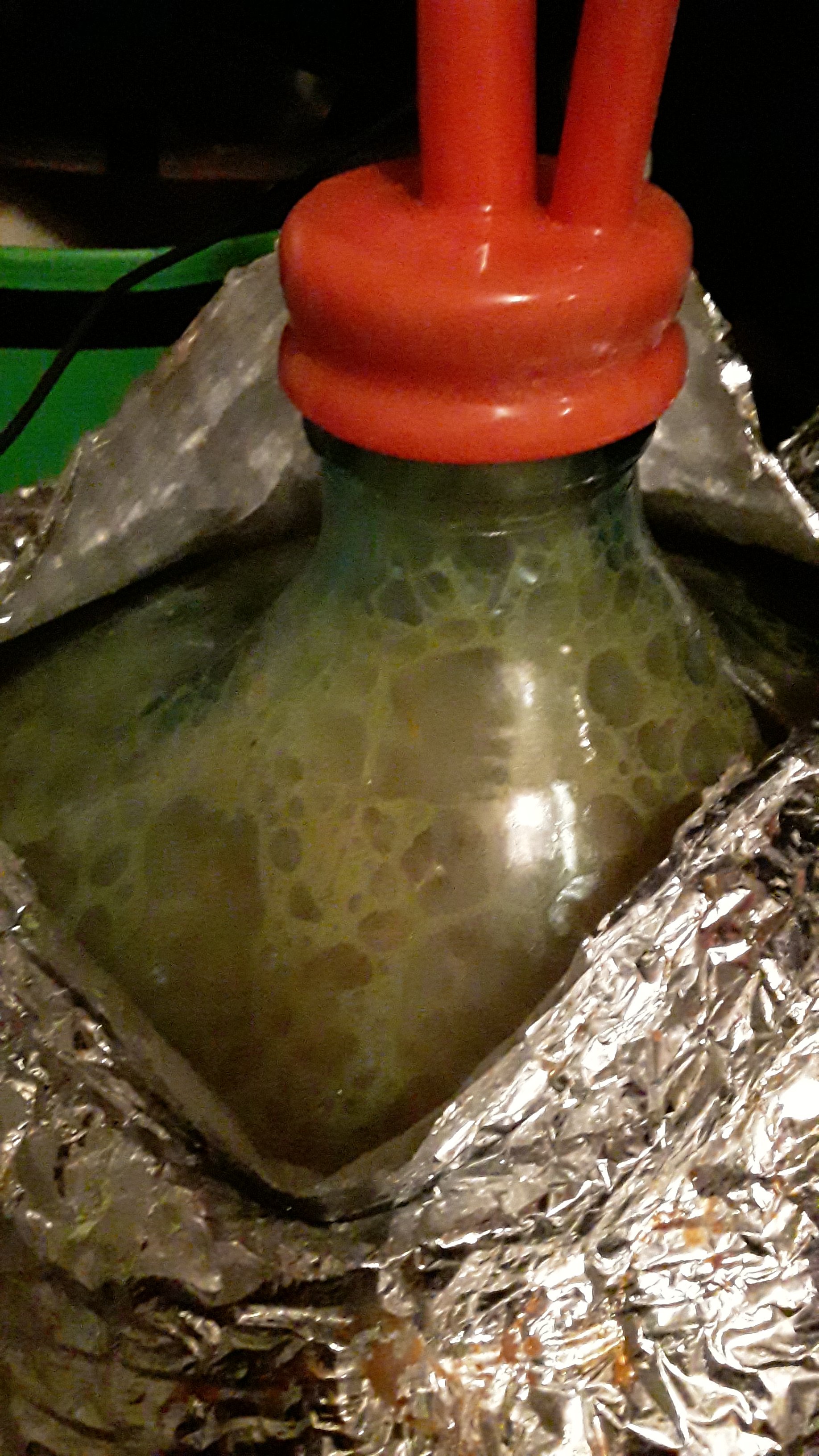

The Kveik strains sure are interesting, they are fast, the beer needs little to no aging (you know the whole grain to glass in 3-4 days thing). But does this apply to cider? I am aim to find out. Today, I bottled about 2.5 gallons of cider that had reached a FG of 1.001 fermented with opshaug, and siphoned the rest into a 3 gallon carboy for kegging later. The kveik tradition is no carbing, so the bottles will be whatever they end up with 1 gravity point left. I will force carb the remainder and see what I think ( I have force carbed both voss and opshaig in the recent past, but I want to do real comparison between the two from the same batch). I plan to age the bottles.

The questions I want to answer for myself are as follows:

!) will underpitching end up expressing the estery flavors in a cider as they are touted to in beer? So far, my ciders end up tasting really clean and crisp, definitely not complaining, but I'm not so sure about the mango, or citrusy notes that are supposed to come with the kveik strains. Maybe I don't have a talented palate...

2) Can it finish, that is, be totally drinkable as though aged when it reaches target FG without aging? My experience thus far says yes for both Voss and Opshaug. But I wonder what others would think, others that know what to look for in a cider

3) How much effect will fermentation temperature have on the cider? High temps in the upper 90's to 104F, vs upper 80-'s low 90's. How much appreciable affect will temps have on cider vs beer?

4) Is secondary necessary? Or can I go straight to bottle/keg once desiredFG is reached without off flavors? I am doing this now as I stated above. I did drink a half pint straight out of the keg, wasn't bad. silky mouth feel perhaps? Tasted good, but I'll see after a few days and once it's refrigerated. I am not accustomed to room temp cider, and not sure what its supposed to taste like

5) Should I treat cider like beer when it come to kveik ferments. or is cider a whole other animal

Are any other cider makers here fermenting with a Kveik strain(s)? What are your findings thus far? The beer guys have plenty to say, but cider is its own thing as far as I can tell, first off, we don't brew, and out base is apple juice instead of boiled grain. I wonder, is out process going to different at the end of the day?

The Kveik strains sure are interesting, they are fast, the beer needs little to no aging (you know the whole grain to glass in 3-4 days thing). But does this apply to cider? I am aim to find out. Today, I bottled about 2.5 gallons of cider that had reached a FG of 1.001 fermented with opshaug, and siphoned the rest into a 3 gallon carboy for kegging later. The kveik tradition is no carbing, so the bottles will be whatever they end up with 1 gravity point left. I will force carb the remainder and see what I think ( I have force carbed both voss and opshaig in the recent past, but I want to do real comparison between the two from the same batch). I plan to age the bottles.

The questions I want to answer for myself are as follows:

!) will underpitching end up expressing the estery flavors in a cider as they are touted to in beer? So far, my ciders end up tasting really clean and crisp, definitely not complaining, but I'm not so sure about the mango, or citrusy notes that are supposed to come with the kveik strains. Maybe I don't have a talented palate...

2) Can it finish, that is, be totally drinkable as though aged when it reaches target FG without aging? My experience thus far says yes for both Voss and Opshaug. But I wonder what others would think, others that know what to look for in a cider

3) How much effect will fermentation temperature have on the cider? High temps in the upper 90's to 104F, vs upper 80-'s low 90's. How much appreciable affect will temps have on cider vs beer?

4) Is secondary necessary? Or can I go straight to bottle/keg once desiredFG is reached without off flavors? I am doing this now as I stated above. I did drink a half pint straight out of the keg, wasn't bad. silky mouth feel perhaps? Tasted good, but I'll see after a few days and once it's refrigerated. I am not accustomed to room temp cider, and not sure what its supposed to taste like

5) Should I treat cider like beer when it come to kveik ferments. or is cider a whole other animal

Are any other cider makers here fermenting with a Kveik strain(s)? What are your findings thus far? The beer guys have plenty to say, but cider is its own thing as far as I can tell, first off, we don't brew, and out base is apple juice instead of boiled grain. I wonder, is out process going to different at the end of the day?

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)