Zulu

Well-Known Member

Glad you are up and running.

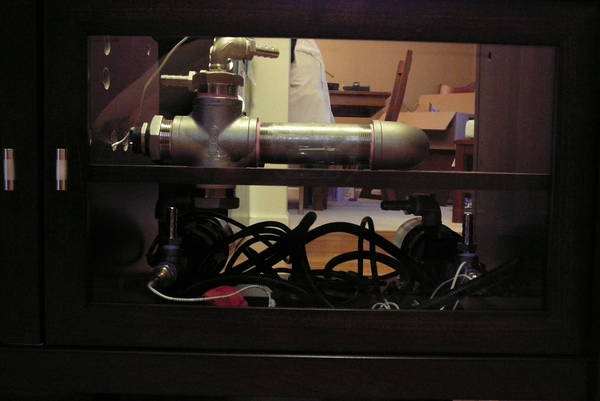

I love the BCS, was one of the beta testers and have had a lot of fun in last 18 months. While I typically only use it now for the basics of running the RIMS, I have programmed and played with many other settings and arrangements but not got the time to implement them yet !!!

Your whole project looks like fun.

As for wireless, man I tried a number of routes in early days , including bridges, and kinda gave up , I now run a seperate old linksys router with own wifi network for the brewery, and just toggle between wifi networks on my laptop if I need internet. It is rather nice being able to mash in and sit at breakfast table and monitor the brewery in warmth.

have fun , shout if you need help

Rick

I love the BCS, was one of the beta testers and have had a lot of fun in last 18 months. While I typically only use it now for the basics of running the RIMS, I have programmed and played with many other settings and arrangements but not got the time to implement them yet !!!

Your whole project looks like fun.

As for wireless, man I tried a number of routes in early days , including bridges, and kinda gave up , I now run a seperate old linksys router with own wifi network for the brewery, and just toggle between wifi networks on my laptop if I need internet. It is rather nice being able to mash in and sit at breakfast table and monitor the brewery in warmth.

have fun , shout if you need help

Rick

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)