I am asking some stuff of a guy I work with. He deals with a bunch of panel shops, integrators and Electrical Distribution companies and works on all kinds of automation projects. I think he is looking at my questions from an industrial viewpoint versus home based. Also, I might not be explaining myself too well either. I also got online and accessed some configurators on various websites, and they pointed me to some higher end stuff.

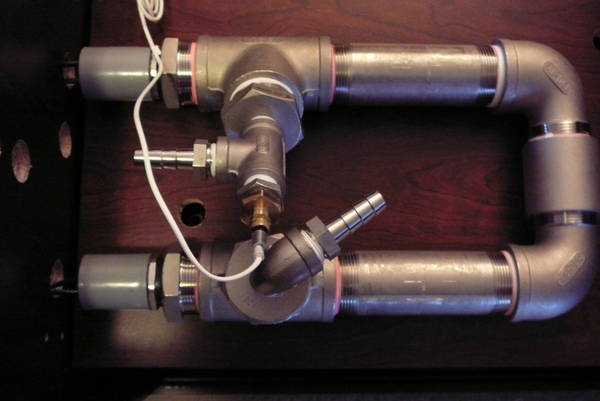

Basically, I am looking at a 5500w element in the Liquor Tun and Boil Kettle, PID controlled and using pumps to move everything. So I need to control boils and strike temps.

As far as thermocouples, that is what the person I asked said to look into, but I am not locked into that at all.

also, any idea if an OMRAN PID (E5CJ) is a good fit for my build out? I have a few of these that I got for free....

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)