rkhanso

Well-Known Member

- Joined

- Jan 24, 2017

- Messages

- 785

- Reaction score

- 178

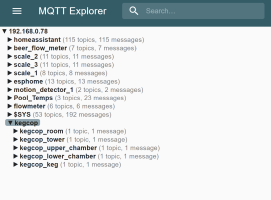

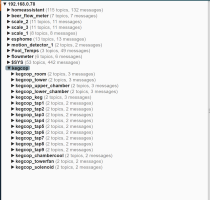

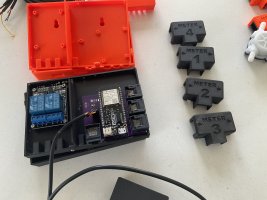

Well, Keg Cop is running with 4 temp sensors connected, I just don't have a solenoid connected and it actually controlling the Kegerator. I'm checking it's running stability only. I can easily switch the Kegerator over from BrewPiLess to Keg Cop, but thought I'd just let it simmer on its own to see how it ran.

If the web server is not an indication of how it would really control temperatures (the controller not locking up, resetting, losing configs, etc), that's good news.

Later today or this week, I'll get Keg Cop actually controlling the kegerator temps and also have CraftbeerPi3 running to measure/graph temperatures to see if when the webserver acts up and the ESP crashes/reboots, if the temp control continues to work through that.

If the web server is not an indication of how it would really control temperatures (the controller not locking up, resetting, losing configs, etc), that's good news.

Later today or this week, I'll get Keg Cop actually controlling the kegerator temps and also have CraftbeerPi3 running to measure/graph temperatures to see if when the webserver acts up and the ESP crashes/reboots, if the temp control continues to work through that.

Last edited:

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)