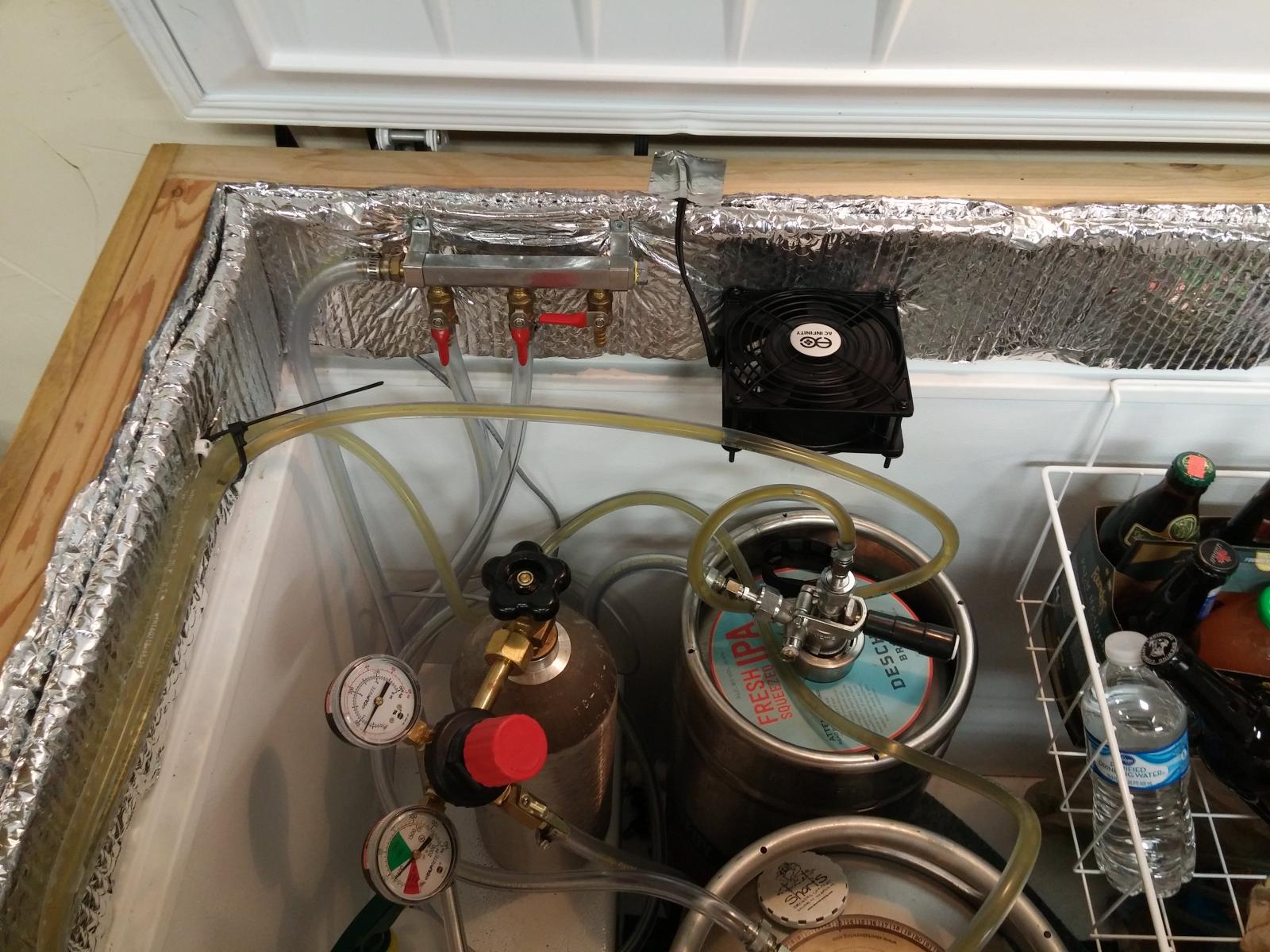

What is that insulation stuff? I should probably get some and build one of those fan attached to PVC to help with circulation and condensation.

Reflectix. They have at Home Depot. Light, cheap and easy to work with. I just taped it it with the foil tape. It's good too to insulate electric boil kettles, mash tuns, etc.

Yeah, I saw those pvc builds for air movement. I think that is my biggest issue right now. That small fan I have to move air around is not cutting it.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)