Im a cheep and lazy Bastard. A deep pan or storage box for $6 with water and a tray of ice cubes every 8-12hr is fine.

I did build a coldwater recirculation system relatively inexpensive and used for years. The 8gal plastic fermenter fit inside the 10gal boil kettle. I placed the bucket in the kettle filled about 90% to top. Then placed the 2 ends of a tube, one was open for return, the other attached to a cheep homer aquarium pump. The tubing would couple with a coil of copper originally used for wort chilling. The copper was submerged in an ice bath from the 10gal homer cooler converted to mash tun. The aquarium pump was driven by a $15 temp cotroller from amazon. I built a box around it with spare wood. Worked great.

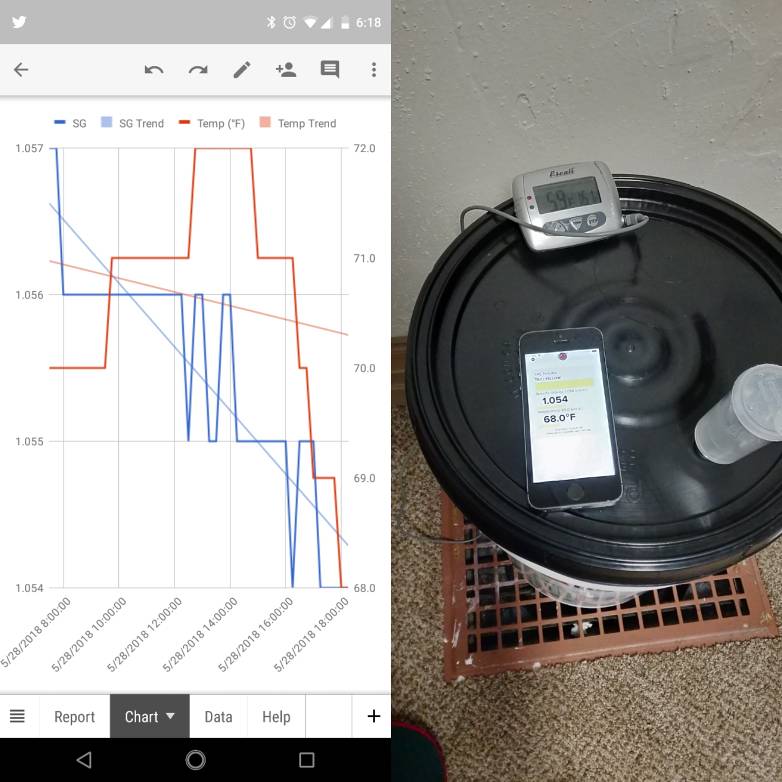

Water is like 1000% more efficient then air with heat transfer. So after experimenting, realized only have to do about 2 days of temp control. I'll start once I see fermentation action and end 1.5 to 2 days later and let the temp rise to room temp. During winter months the house gets onto the 60s so water only is fine. No body noticed any beer quality difference.

Temp control is ultra-important but the cheep/easy method is the way to go for me.