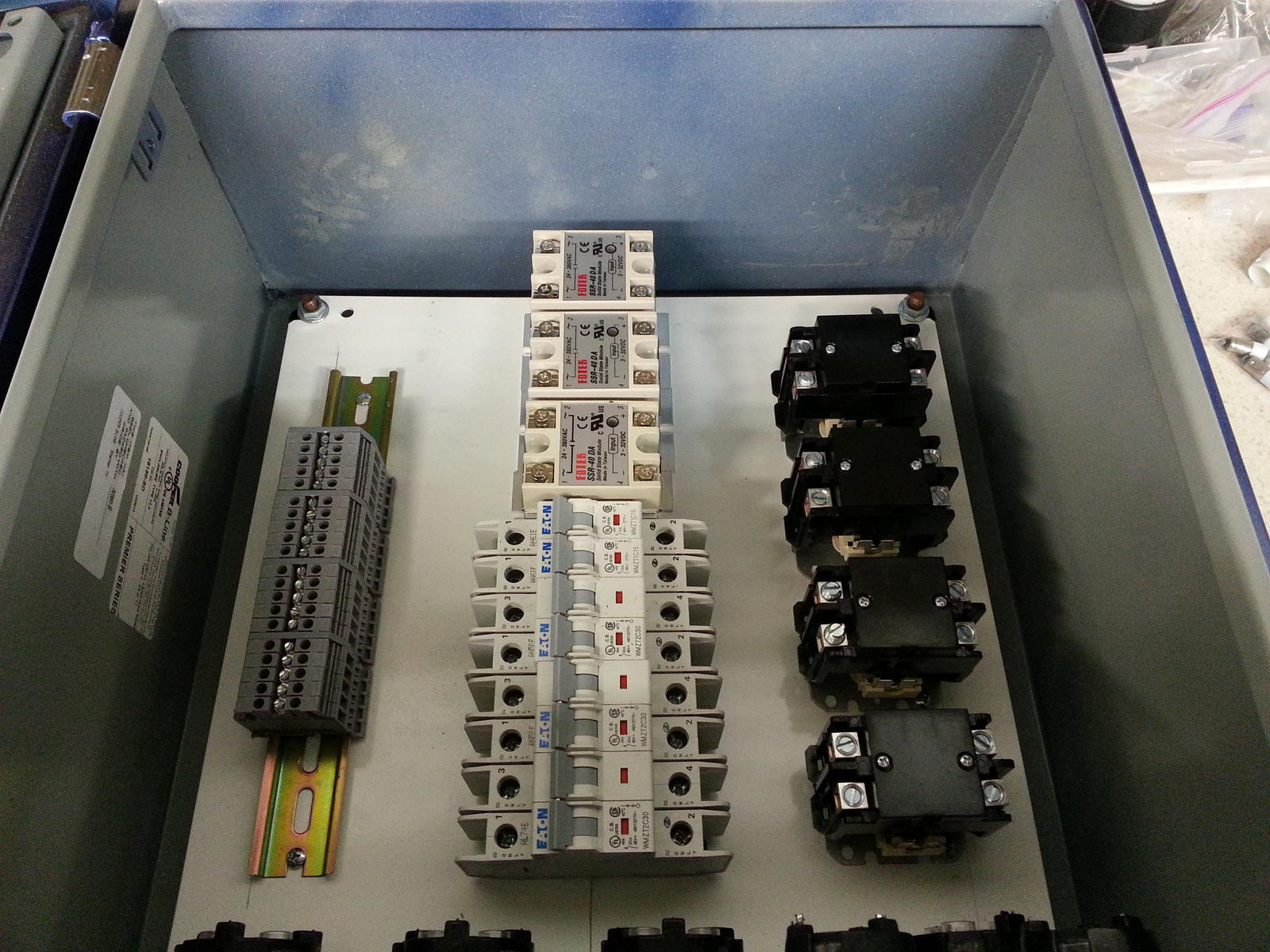

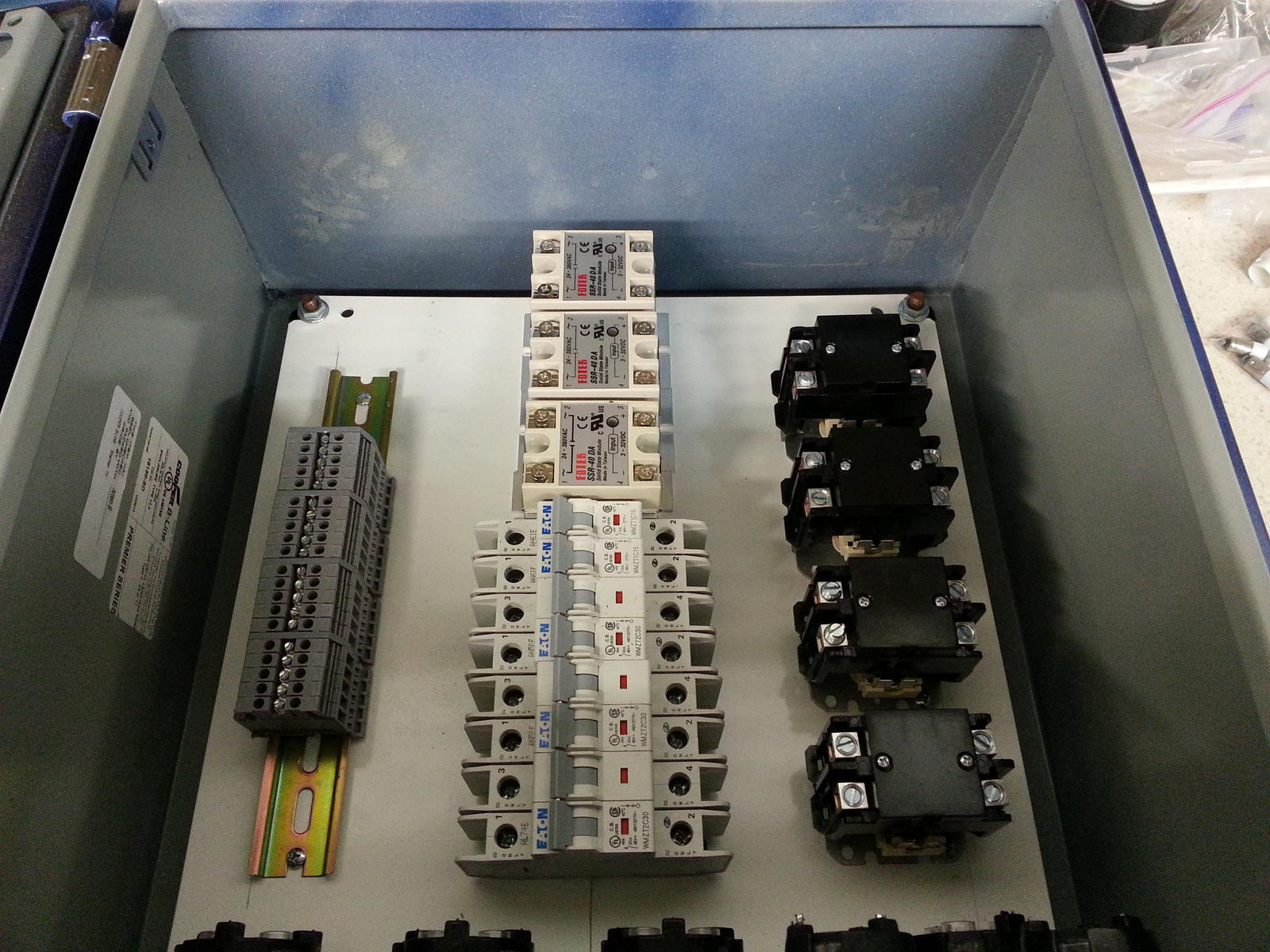

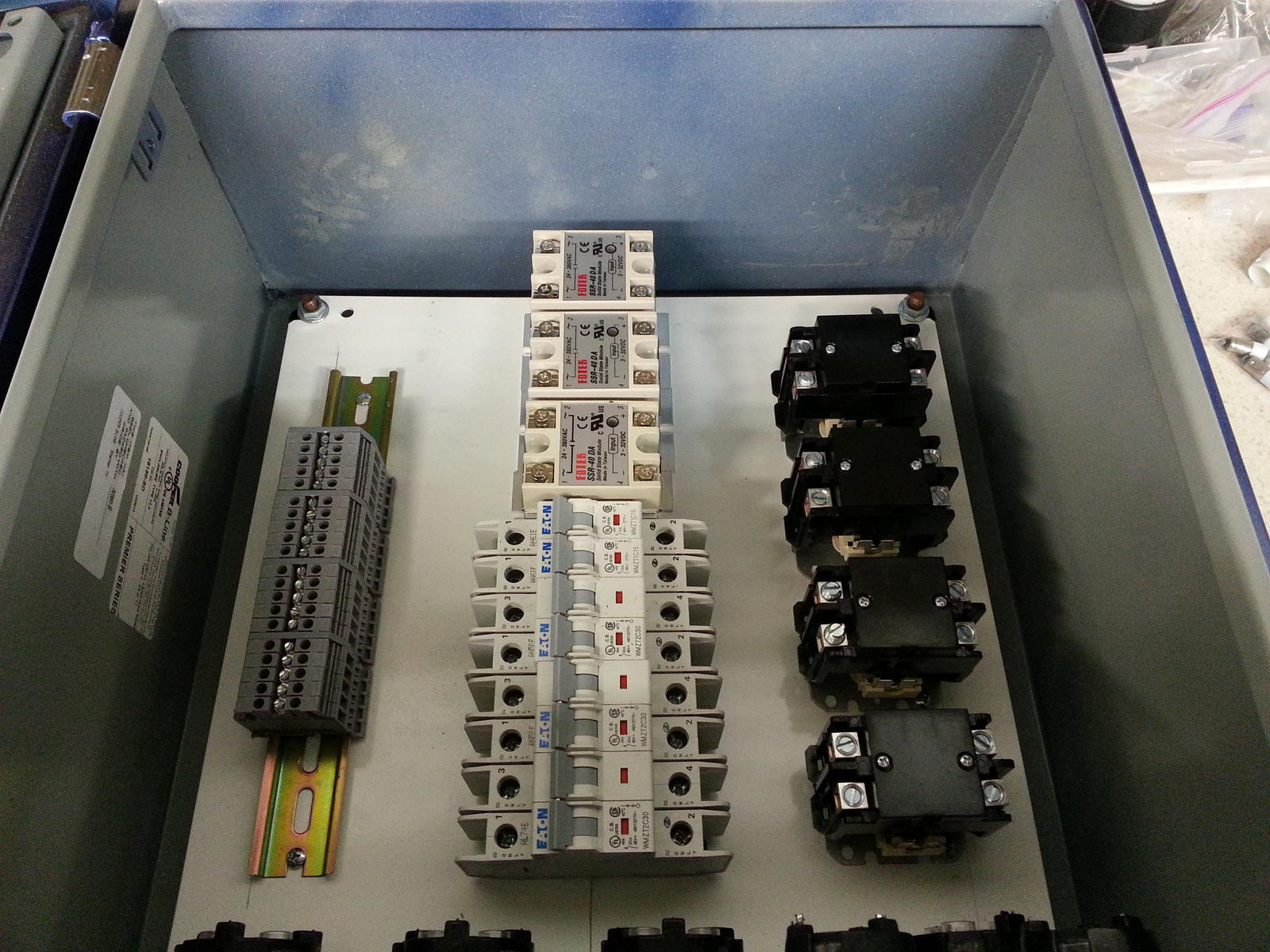

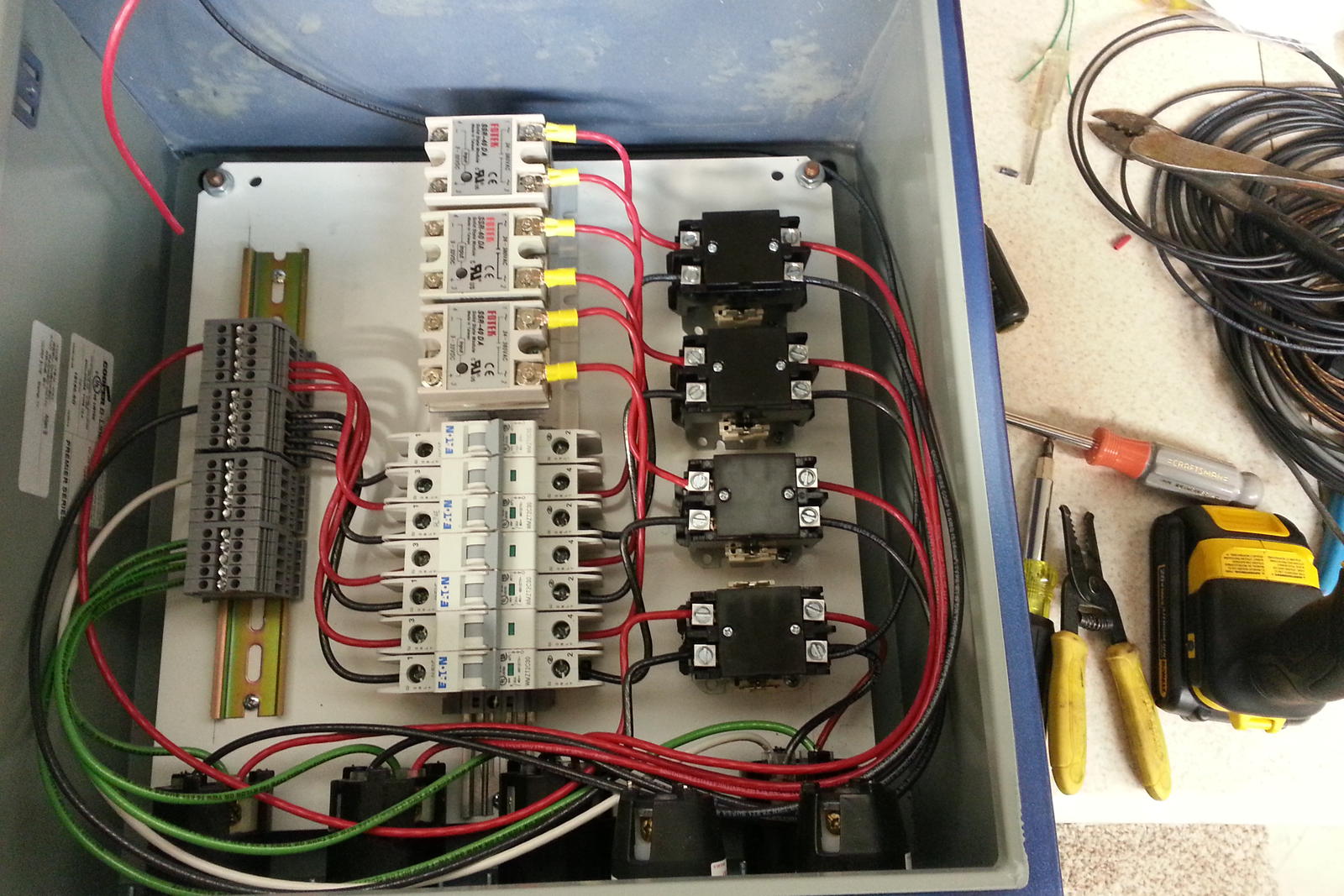

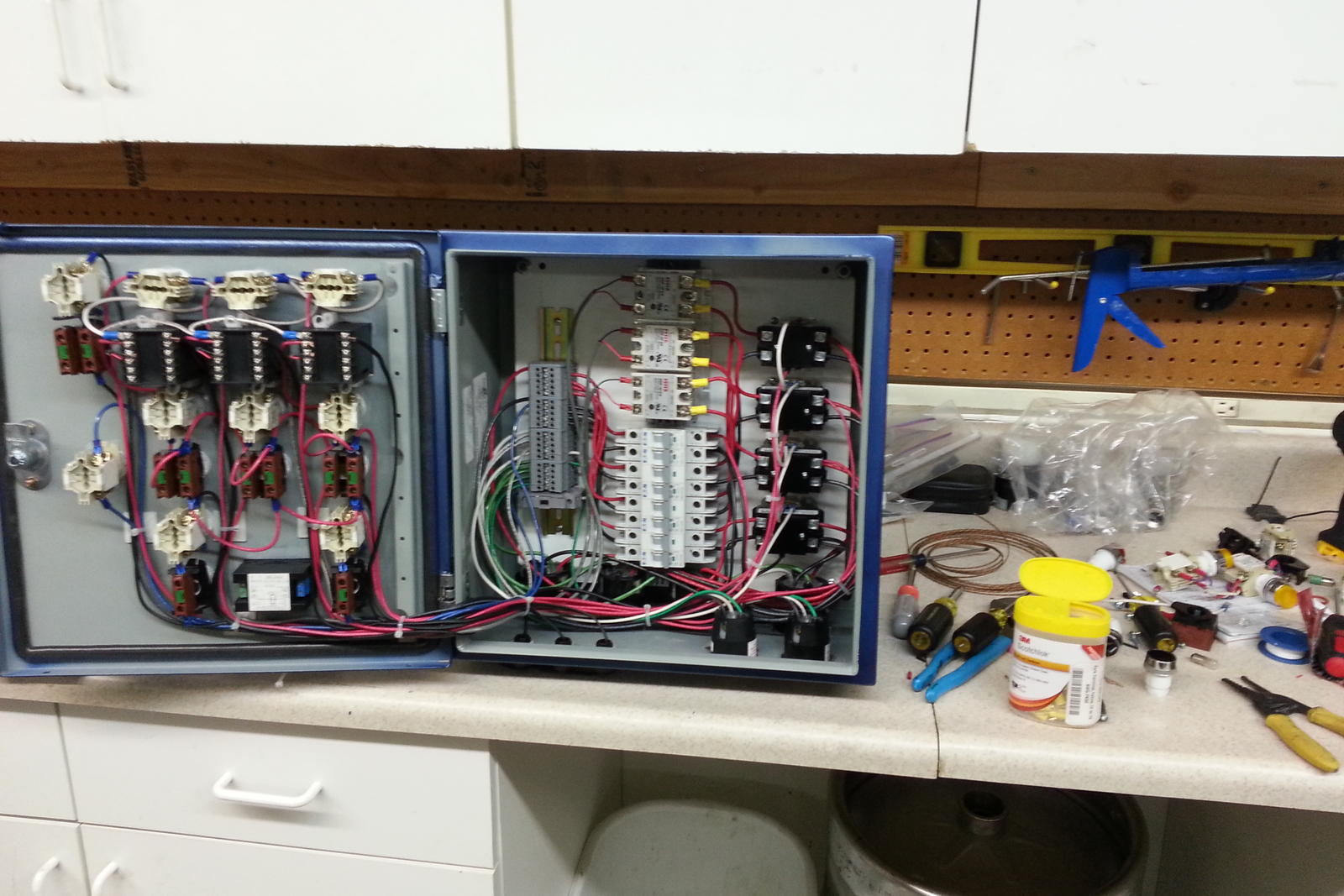

I have been working on my control panel the last few weekends and am interested to know what you guys think. I still need a way to attach my Thermocouples and another piece of din rail.

You can use something like this for your thermocouples. Just buy the mini tc connectors

http://www.omega.com/pptst/UPJ.html

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

Yes it was tight next time one up on my box size.That looks great you get an (A). Now grasshopper, wire like the wind, (keep everything tight, because that is going to be a stuff job).

Looks awesome!

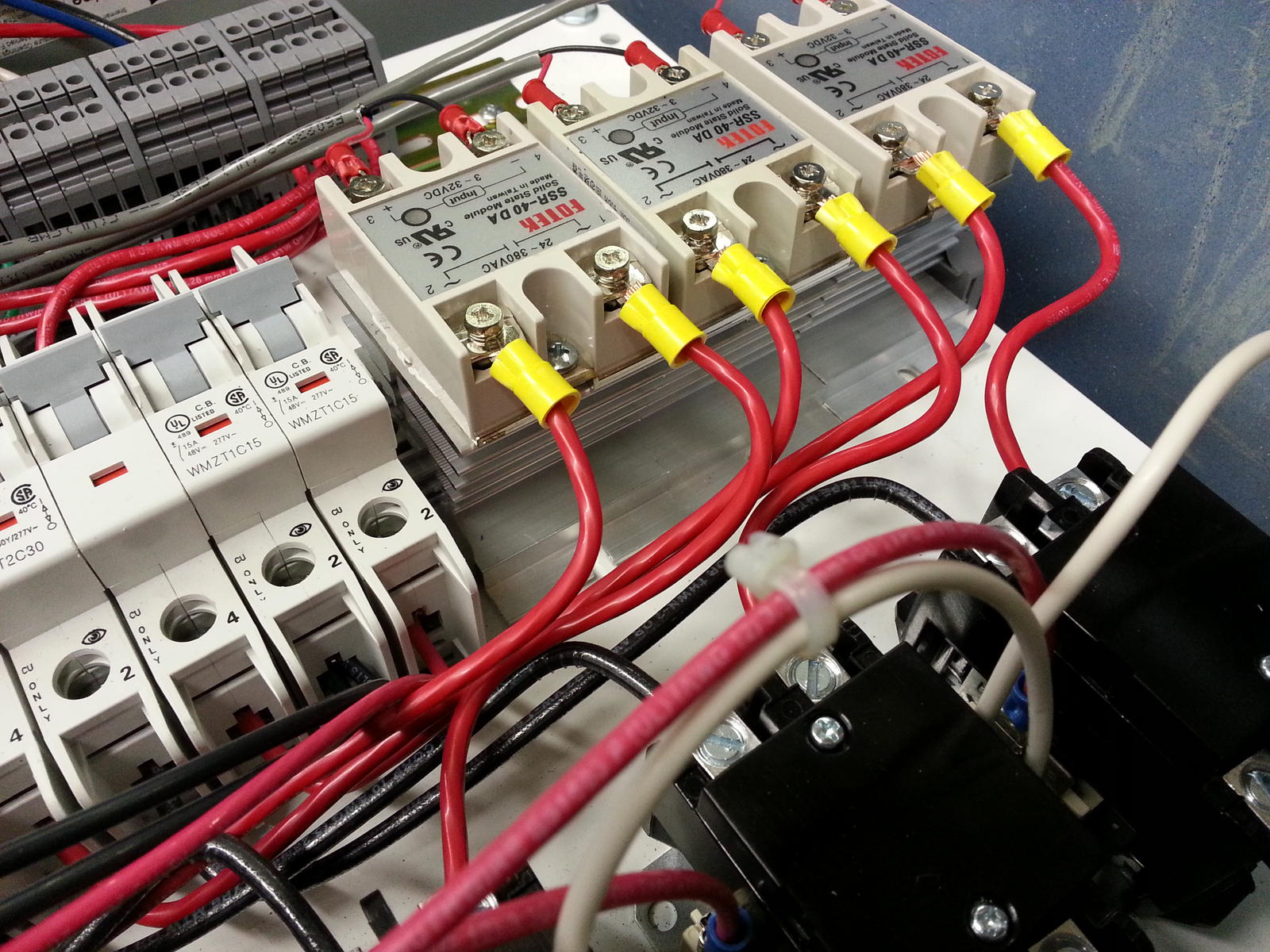

What are those four black components to the right next to the relays and breakers?

they are maniacal relays

Do the let out an evil click when they close?

Seriously...no heat syncs? I'm about to build similar

Sent from my iPad using Home Brew

Heat Sinks are there just cant see them.

What is the benefit of mechanical and SSR?

Spare PIDs too. Heat greatly reduces the lifespan of electrolytic capacitors (which are found in most electronic devices, including PIDs).Those heat sinks are going to get pretty hot in that enclosure. You might want to think about a fan and a vent. And have some spare SSR's handy.

16x16x8What size is the enclosure?

I have a 50 amp, 240 vac system. I run two 4500 watt elements in both my HLT and BK. My heat sinks are mounted to the back panel. Granted my heat sinks are bigger and my enclosure is bigger (20X16X8), but I have no ventilation system and my SSRs barely get warm. I have had the same Crydom (40 amp) SSRs for 8 years with no failures. I have replaced one Omega PID but I purchased it used. The size of the heat sink and enclosure will make a significant difference so my situation is not universally applicable. YMMV.