EinGutesBier

Well-Known Member

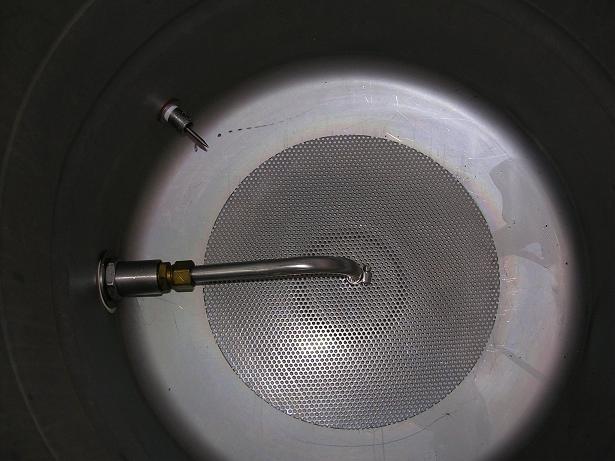

I hate to be the odd man out, but what's an easymasher? I did a quick search for it and it didn't give me an idea of what it is. This might be a good solution to consider.Warrior said:Got the keg out for mashing tomorrow. It took about 2 3/4 gal to reach the copper plates. I'm doing a 5 1/2 gal Bock tomorrow. I'm figuring 13 1/2 lbs of grain to get around a 1.070 gravity at the end of the boil. 6 gal of water for the mash (3 1/4 actually mixed in the grain) and 5 1/2 gal for the sparge. I threaded the easymasher in the keg fitting also. This will syphon most of the wort out of the kettle and the screen around the easymasher should help the runnings to get clear much faster than just using a dip tube. I'll let you know the results this weekend.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)