I did the pro/am yesterday at Forgotten Star. Brewed 15 bbls of Grodziskie. Had a blast!

The brewery is located in a 1920s factory building that has a very colorful history. It was a pump manufacturer in the '20s and '30s, but after Pearl Harbor, its mission switched to building naval guns. The "E" and the stars painted on the left smokestack denote quality awards the company earned from the War Dept. in its service during WWII. The industrial park it sits in still holds manufacturing facilities for BAE Systems, nearby.

Forgotten Star has been here since 2019.

I started at 8AM, and Matt, the head brewer said I could participate as much or as little as I wanted. Of course, I chose "as much," as I wanted to get my hands dirty and learn some things. His two assistant brewers were also on hand, so we had a good crew.

Matt followed my recipe, but with an adjustment. Mashing 100% wheat was too risky, so we went with 50/50 Weyermann Pilsner and Weyermann Oak Smoked Wheat malt, with 3% acid malt for pH adjustment. Didn't want a stuck sparge.

Aside from that, Matt wanted to stick close to my recipe. Same hops (Saaz), and same yeast (Chico). Even getting close to the same water I used. About 50ppm Ca, and around 60-70ppm sulfate and chloride. The brewery builds its water from RO. They are even planning to use the name I suggested, "Smokestack Lightning," from the old Howlin' Wolf song. It's not a true-to-form Grodziskie, but something the brewers think will appeal to their customers.

Their auger is not working so I volunteered to hump bags of grain up the stairs to the mash tun, just over 900lbs. I needed to work off some Thanksgiving pounds.

We mashed in at 150, took a pH reading after about 20 minutes. It was high, despite the acid malt, about 5.65. So they added some phosphoric acid and we soon had pH down to around 5.45.

Recirculated for about a half hour, then time to rack into the boil kettle.

We did a 60 minute boil with Magnum at 60, then Saaz at 10.

At knockout did a whirlpool for 30 minutes. Left that kettle trub behind.

Pumped the wort through the chiller, oxygenated, and racked to the FV.

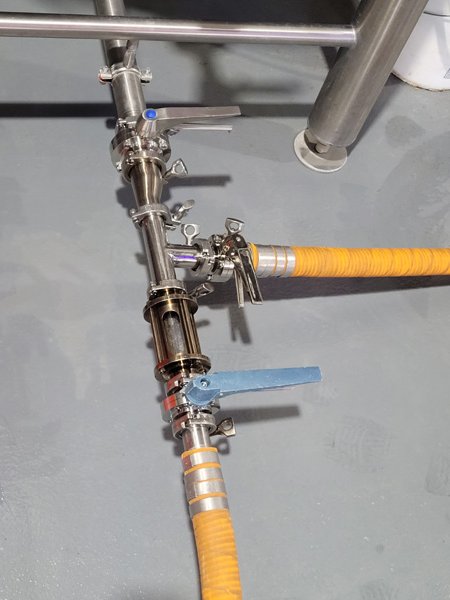

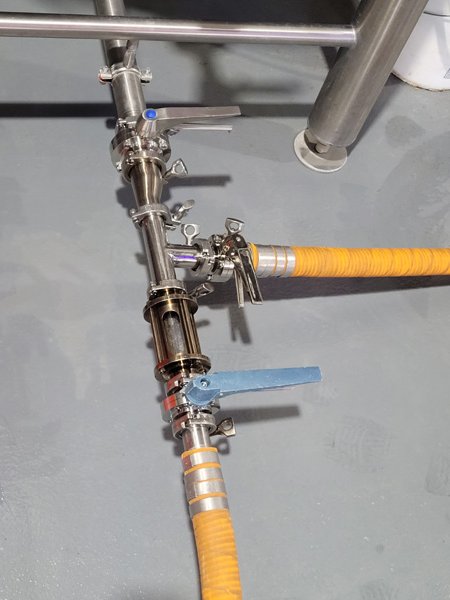

Using at T-connector with valves we purged the sanitizer from the line, used a sight glass to see when the wort flowed in. Then switched the valves and up it goes into the FV. Ferm temp was set to 65. OG was 12 Brix. They're shooting for a FG of about 3 Brix, and an ABV just north of 4.5%. The beer should be ready to serve in 2-3 weeks.

They crop their yeast--up to 20 generations for ale yeast and 7 or 8 gens for lager--and had a fresh batch of Chico pressurized in a 16 gallon keg. They connected it via a hose to the T, and pumped in 15 lbs about halfway during the racking, so it would be well-distributed in the FV. One of the brewers told of a time when a bunch of cropped yeast blew out of a keg (something not connected), so I decided to step back a few paces. They don't measure cells, but use a rule-of-thumb of just over 1 lb cropped yeast per degree Brix for a 15 bbl batch of ale, double that for lagers. They put the keg on a scale, tared, then force fed it to the FV until the scale read minus 15 lbs.

They don't measure cells, but use a rule-of-thumb of just over 1 lb cropped yeast per degree Brix for a 15 bbl batch of ale, double that for lagers. They put the keg on a scale, tared, then force fed it to the FV until the scale read minus 15 lbs.

Then, the fun job of cleaning the spent grain from the mash tun. We scooped it into several rolling tubs and took it outside. A farmer stops by each week to take it away for hog feed.

After cleanup, we hung out a bit. I brought a couple homebrews for the three brewers to sample and give feedback. Then Matt asked if I needed any malt. They had a bunch of Pilsner and Munich I approaching their use-by dates (Feb 2024). It's still good (we used 440 lbs of Pilsner that day), but they wouldn't use the rest of it. He said to take as much I wanted. So I grabbed a few bags. More than I can use, but will give some away. It was a nice, generous gesture, as my time there was as an unpaid internship sort of arrangement and I wasn't expecting anything.

I had a chance to talk general brewing topics with Matt, as there are lots of little downtime periods during the process. Forgotten Star is content to keep brewing for the taproom and crowler/growler sales. They have no plans at this time to package and distribute, as the margins are quite thin and it brings in a lot a middlemen.

They are venturing into some barrel-aged beers. In fact, a guy from a nearby distillery came by to drop off some rye whiskey barrels that morning.

Their beers have won gold and silver medals from GABF, Minnesota Brewers Cup and US Beer Open Championship. They just added a new oatmeal stout so I'll be visiting later this week to try some. The brewery has food trucks most days, but they are cool with outside food being brought in. Check it out if you're in the Twin Cities, or passing through.

The brewery is located in a 1920s factory building that has a very colorful history. It was a pump manufacturer in the '20s and '30s, but after Pearl Harbor, its mission switched to building naval guns. The "E" and the stars painted on the left smokestack denote quality awards the company earned from the War Dept. in its service during WWII. The industrial park it sits in still holds manufacturing facilities for BAE Systems, nearby.

Forgotten Star has been here since 2019.

I started at 8AM, and Matt, the head brewer said I could participate as much or as little as I wanted. Of course, I chose "as much," as I wanted to get my hands dirty and learn some things. His two assistant brewers were also on hand, so we had a good crew.

Matt followed my recipe, but with an adjustment. Mashing 100% wheat was too risky, so we went with 50/50 Weyermann Pilsner and Weyermann Oak Smoked Wheat malt, with 3% acid malt for pH adjustment. Didn't want a stuck sparge.

Aside from that, Matt wanted to stick close to my recipe. Same hops (Saaz), and same yeast (Chico). Even getting close to the same water I used. About 50ppm Ca, and around 60-70ppm sulfate and chloride. The brewery builds its water from RO. They are even planning to use the name I suggested, "Smokestack Lightning," from the old Howlin' Wolf song. It's not a true-to-form Grodziskie, but something the brewers think will appeal to their customers.

Their auger is not working so I volunteered to hump bags of grain up the stairs to the mash tun, just over 900lbs. I needed to work off some Thanksgiving pounds.

We mashed in at 150, took a pH reading after about 20 minutes. It was high, despite the acid malt, about 5.65. So they added some phosphoric acid and we soon had pH down to around 5.45.

Recirculated for about a half hour, then time to rack into the boil kettle.

We did a 60 minute boil with Magnum at 60, then Saaz at 10.

At knockout did a whirlpool for 30 minutes. Left that kettle trub behind.

Pumped the wort through the chiller, oxygenated, and racked to the FV.

Using at T-connector with valves we purged the sanitizer from the line, used a sight glass to see when the wort flowed in. Then switched the valves and up it goes into the FV. Ferm temp was set to 65. OG was 12 Brix. They're shooting for a FG of about 3 Brix, and an ABV just north of 4.5%. The beer should be ready to serve in 2-3 weeks.

They crop their yeast--up to 20 generations for ale yeast and 7 or 8 gens for lager--and had a fresh batch of Chico pressurized in a 16 gallon keg. They connected it via a hose to the T, and pumped in 15 lbs about halfway during the racking, so it would be well-distributed in the FV. One of the brewers told of a time when a bunch of cropped yeast blew out of a keg (something not connected), so I decided to step back a few paces.

Then, the fun job of cleaning the spent grain from the mash tun. We scooped it into several rolling tubs and took it outside. A farmer stops by each week to take it away for hog feed.

After cleanup, we hung out a bit. I brought a couple homebrews for the three brewers to sample and give feedback. Then Matt asked if I needed any malt. They had a bunch of Pilsner and Munich I approaching their use-by dates (Feb 2024). It's still good (we used 440 lbs of Pilsner that day), but they wouldn't use the rest of it. He said to take as much I wanted. So I grabbed a few bags. More than I can use, but will give some away. It was a nice, generous gesture, as my time there was as an unpaid internship sort of arrangement and I wasn't expecting anything.

I had a chance to talk general brewing topics with Matt, as there are lots of little downtime periods during the process. Forgotten Star is content to keep brewing for the taproom and crowler/growler sales. They have no plans at this time to package and distribute, as the margins are quite thin and it brings in a lot a middlemen.

They are venturing into some barrel-aged beers. In fact, a guy from a nearby distillery came by to drop off some rye whiskey barrels that morning.

Their beers have won gold and silver medals from GABF, Minnesota Brewers Cup and US Beer Open Championship. They just added a new oatmeal stout so I'll be visiting later this week to try some. The brewery has food trucks most days, but they are cool with outside food being brought in. Check it out if you're in the Twin Cities, or passing through.

Last edited:

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)