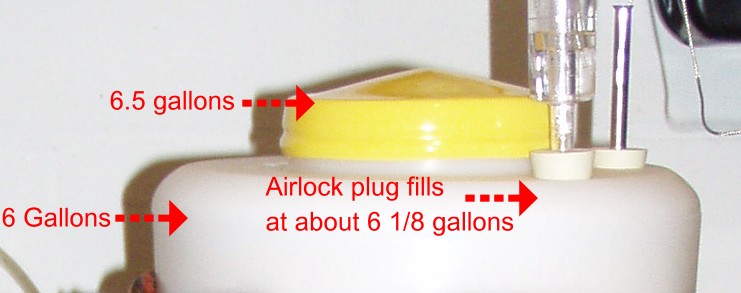

I have brewed 8 batches of extract ale with my Mini-Brew 6.5 conical. This conical has many advantages, but few disadvantages as well. My most recent concern is with the airlock filling with krausen during fermentation. My photo shows that my plug for my airlock sits between the 6 and 6 1/8 gallon mark, and when I ferment 5.25 gallons, and have a vigorous fermentation, my airlock will plug up. I could just ferment 5 gallons, but after dumping the yeast, and taking a couple of gravity readings, I might only have 4.5 gallons left at bottling time.

What I would like to do is just boil and ferment a 4 gallon batch, and add distilled H2O after active fermentation to get back to 5-5 1/2 gallons, but was wondering what kind of negative impact of issues I might run into.

Would I need to boil the water to expel any oxygen? Would I mess up my hop utilization by boiling 4 gallons instead of 5? I am guessing I would need to re-calculate my starter size due to a more concentrated wort gravity? At what point would I add my H2O, after the krausen has subsided, or might I just boil the priming sugar in the amount of H2O I need to top off? What other issues might I have?

Yes I could use a different fermenter, buy a stainless conical, or build a “stack tube” for the airlock plug, but this is the fermenter I have to use for now.

Another potential disadvantage I have found is that it appears that up to 3/8 of a gallon of oxygen might be trapped from the bottom of the airlock plug, to the top of the conical where the plastic lid is secured. CO2 should still give me a layer on top of the beer but I am not sure. I am considering adapting an airlock attached to the lid itself, but since it is flexible it won’t be easy. I was thinking of finding a 6" diameter sleeve (stainless? glass? sched 80 pvc?) and hose clamp it to the top of the conical, then attach my airlock to the top of that. Too bad I have this issue, it is a great product otherwise.

What I would like to do is just boil and ferment a 4 gallon batch, and add distilled H2O after active fermentation to get back to 5-5 1/2 gallons, but was wondering what kind of negative impact of issues I might run into.

Would I need to boil the water to expel any oxygen? Would I mess up my hop utilization by boiling 4 gallons instead of 5? I am guessing I would need to re-calculate my starter size due to a more concentrated wort gravity? At what point would I add my H2O, after the krausen has subsided, or might I just boil the priming sugar in the amount of H2O I need to top off? What other issues might I have?

Yes I could use a different fermenter, buy a stainless conical, or build a “stack tube” for the airlock plug, but this is the fermenter I have to use for now.

Another potential disadvantage I have found is that it appears that up to 3/8 of a gallon of oxygen might be trapped from the bottom of the airlock plug, to the top of the conical where the plastic lid is secured. CO2 should still give me a layer on top of the beer but I am not sure. I am considering adapting an airlock attached to the lid itself, but since it is flexible it won’t be easy. I was thinking of finding a 6" diameter sleeve (stainless? glass? sched 80 pvc?) and hose clamp it to the top of the conical, then attach my airlock to the top of that. Too bad I have this issue, it is a great product otherwise.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)