rabeb25

HE of who can not be spoken of.

I think you guys are smoking something funny if you think a possible MAX concentration of 25ppm sodium is the magic bullet. Dose the beer in your glass with 25ppm sodium. Does that do it for you?

but with that always seems to come the caveat that ascorbic acid, once oxidized (i.e. after it has reduced something), is now an oxidizing agent so that some metabite is usually used along with it.

This is something I don't understand. The Water book, for example, advises brewers to keep potassium additions to below 10 mg/L while at the same time acknowledging that many beers contain (from the barley) as much a 500 mg/L (in fact some contain almost a gram). I don't see how adding 20 mg/L to your water as a source of, say, chloride, is going to be problematical but I haven't tried it. The situation is similar, if not so dramatic, with sodium and yet the lore allows us greater flexibility in how much sodium we can add. Something doesn't compute here.I think you guys are smoking something funny if you think a possible MAX concentration of 25ppm sodium is the magic bullet. Dose the beer in your glass with 25ppm sodium. Does that do it for you?

This is something I don't understand. The Water book, for example, advises brewers to keep potassium additions to below 10 mg/L while at the same time acknowledging that many beers contain (from the barley) as much a 500 mg/L (in fact some contain almost a gram). I don't see how adding 20 mg/L to your water as a source of, say, chloride, is going to be problematical but I haven't tried it. The situation is similar, if not so dramatic, with sodium and yet the lore allows us greater flexibility in how much sodium we can add. Something doesn't compute here.

Look on page 234 of Kunze and you can see chemiluminescence detection-based measurement of oxidative reactions in the mash.

I have the 4th Edition of Kunze's book and it appears that the pagination is not consistent with that of your edition. Could you describe the chapter title and subsection that you are referring too. I do want to read about this.

I'm assuming BIAB is out of the question for this low oxygen technique since the bag is squeezed (pretty hard in most cases). Squeezing would introduce oxygen during the squeeze and the splash back into the MT/BK.

Depends on how you do it. Lift the bag up a little at a time instead of just pulling it right out a foot above the kettle. Once most of it is drained remove bag to a bucket or another kettle and let it drain naturally and add that wort back to the boil.

Probably would send my efficiency from 78 to 55. I guess that's part of the sacrifice for low oxygen.

Really wish I had a DO meter. Even if I wasn't shooting for all the steps itd be interesting as to how much oxygen gets introduced during my normal process.

Nah, you won't lose that much, maybe a couple points if that. Squeezing doesn't really give better efficiency just gives you an extra cup or two of wort.

There are a whole passel of craft brewers that don't do half of what you're advocating, and they're still making amazing beer. I don't do this stuff, and I've gotten a ribbon or two for my brews.

Can it make a difference in the finished product? Maybe. Is it worth the effort to chase some 'special, elusive flavor'? In my opinion: No. The return for all the effort/equipment seems too small, potentially nonexistent.

I'm all about limiting O2 pickup after fermentation, and I'll probably start adding O2 after pitching yeast based on some of the info. Other than that, some of what's been passed on seems too much like faith based gospel.

In closing, I leave you a humorous image:

The science is very sound, so to me it is worth learning more and conducting the mini-mash test.

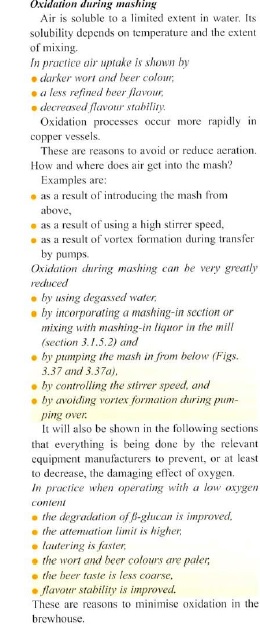

Obviously there are oxygen dependent reactions in the mash...

If indeed some German breweries are using special techniques to exclude oxygen then I think we can take this as proof that the capital investment is more than offset by increased sales for those breweries. Note that increased sales and better beer are not necessarily the same thing. At the same time I think we can take the continued use of sinks in breweries like Pilsner Urquell as evidence that at least some markets like some oxidized flavor.

I wouldn't be so quick to dismiss the validity of the claims unless you have experienced them firsthand. The science is very sound, so to me it is worth learning more and conducting the mini-mash test. It sound like you don't like the possible reality that what we have accepted as gospel may not be correct. You are certainly entitled to your opinion but I will personally withhold judgment until I disprove the claims (or not) myself.

The implication is that it is oxidized malt compounds that are volatile and, thus, responsible for malt aromas. That is, of course, a hypothesis on my part.Their comments about there being no malt aroma from the mash as proof that the mash is not being oxidized are certainly curious. What is the science there?

Yes, and that's what the comment about the sinks at PU was supposed to convey.Are not world class examples of every style made without using special low oxygen techniques?

I'm not being quick to dismiss their claims.

Where's the 'science'?

That test mash fails as conclusive proof one way or the other. You are using different parameters in the main part of the testing medium (water) which may introduce other changes in the outcome (mineral composition of the wort, other alterations in mash reactions) that render any conclusions suspect, at best.

A real apples to apples comparison would use deoxygenated water in one test, not an additive to suppress oxygenation that consequently changes the mineral composition and potentially alters other reactions going on in the mash. Then perform a second mash with the *same* water, sans the de-oxygenating step. Both worts must be boiled, hopped, fermented with the same yeast strain, etc. Then, the *final* product can be tested to see if it made any appreciable differences.

There's a distinct lack of conclusive proof that all this effort and energy expenditure makes an iota of difference in the finished product. I'm not terribly concerned with how the wort tastes, I'm concerned with how the finished beer tastes.

The problem with the 'paper' is that it's presented in a very 'gospel' like way, that 'this is the only way to do things' in pursuit of an 'elusive, special flavor' without any real testing of a *finished product*. The wort is an intermediate step to finished beer. Differences there may not translate into meaningful changes in the finished product.

In short? You could post the hypothesis that there may be a benefit to reducing oxygen introduced during the mashing process, instead of proclaiming "OMG guys I totally found the holy grail of that 'special elusive' flavor and here's the only way to do it!" and there might be a little better reaction to what the hypothesis is and more open discussion.

There is a distinct lack of conclusive proof that drinking a glass of plutonium will kill you, but the concept of radiation toxicity is nonetheless well appreciated.

Do or don't what you like. The author proposed adding sulfate to the non-DO water to make the waters similar, but I know you'll continue to find reasons to say the proposal is crap no matter what, likely because it contradicts your accepted beliefs and practices. I'm open to the idea and will decide after I have direct experience.

I'm not being quick to dismiss their claims.

Where's the 'science'?

I would love to read the Kunze books. However, the price tag puts them out of reach... for now.

I think you can keep beer that fresh by limiting O2 post ferment. Again, I'm not saying the process doesn't work; I'm just wondering how viable it is on a small/homebrewer scale.

I brew single vessel electric with a stainless basket. It wouldn't be hard to test this process with the setup I have, as I can put my milled grain in the basket (I condition already) and slowly lower the grist into the kettle after boiling/Metabisulfite. The problem is my chiller is a copper counterflow and I can't see changing it out for a test.

If it does pan out, as it states on Braukaiser's site, it may only be useful for a small subset of beers.