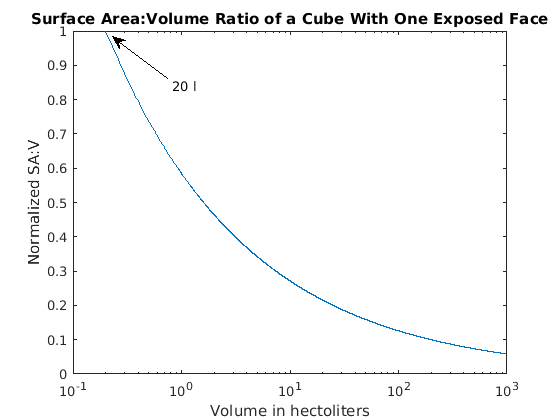

For anybody who might think that this is only a "big brewery" problem that doesn't matter at "home-brew scale", the reality is that oxygen ingress at home-brew scale is many times higher than at commercial scale due to the larger surface area to volume ratio of a home-brew system:

The arrow marked "20 l" points to a 20 liter, home-brew sized system. You can see that from 100 hl (~85 bbl) and larger, the surface area to volume ratio is less than 1/10 as much as a home-brew system, getting close to 1/20 for 500 hl systems. This means home-brew systems experience more than 10-20x as much oxygen exposure as a commercial system under normal conditions.

that's only an accurate statement if 100% of the oxygen uptake during brewing occurred via absorption through the surface of your brew kettle, which you just argued was not the case. You get oxygen during milling, during mashing in, during pumping, during stirring, during siphing... And there is far less of all of these things in homebrewing.

You also have to take into account the reduced time everything takes on the homebrew scale. Gas diffusion is a relatively slow process, so by simply reducing your mash-in time from hours to seconds, you're reducing the oxygen exposure exponentially.

I'm speculating obviously, but I would like to see a plot of TDO during a homebrew brew day, vs a small brewpub brew day. I would be willing to bet that overall, an average homebrewer has less TDO integrated over the brew day as compared to a craft brewery.

At the end of the day it's just not practical to remove oxygen from your mash without lengthening your brew day substantially (mine is 3.5-4 hours on average from filling the kettle to finish cleanup). And for me that amount of work just isn't worth the very minor (IMO) benefits.

I make pretty good beer without all the extra fuss, and my german lagers come out great. I'm not chasing some white whale here, I just haven't ever made this style before, and that was the point of this thread: to distinguish between Marzen, American Oktoberfest, and Tent Beer. I make a damn good pilsner and doppelbock that have a very full malt characteristic with no "flatness" or stability issues. What I'm doing is working for me.

I'm sorry if I got a little heated.