I also find it difficult to follow....

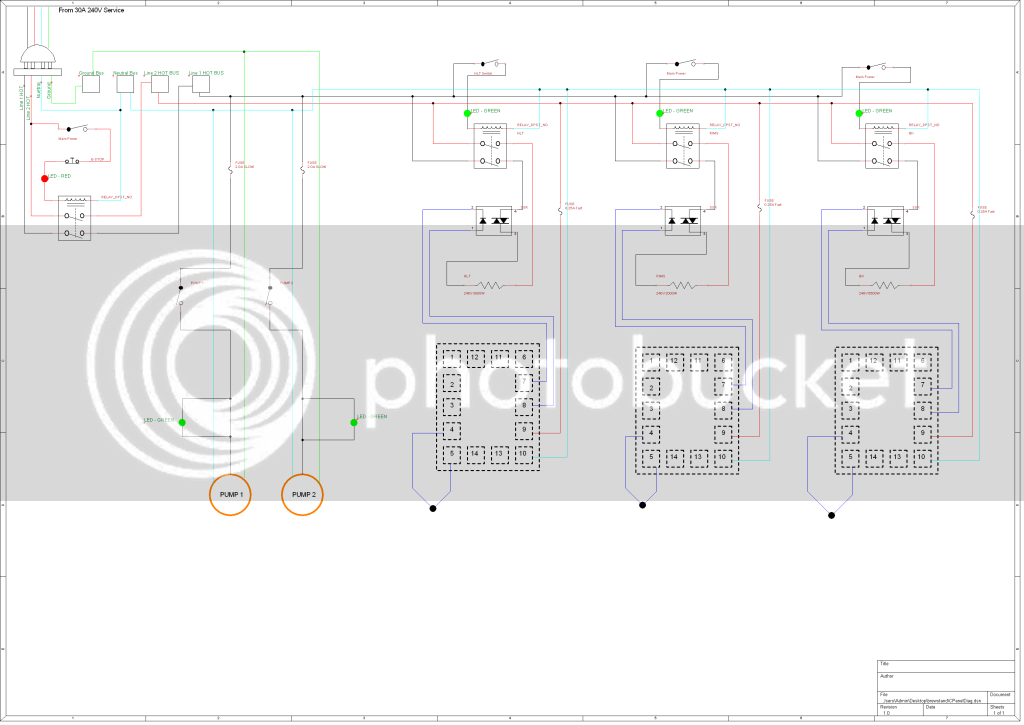

These pictured wiring diagrams are sometimes hard to read. For example, I can't tell exactly how your DPDT relays are wired. You have 6 terminals and 9 wires all on one relay. If you could please provide a little more detail so that we can give you better quality input.

You are right. (I think) Best I can figure the way it is now - The HLT and BK are interlocked. BUT - It is possible to fire the RIMS along with either the HLT or the BK. That's over 30A (not counting PIDS or pumps) with the BK and RIMS fired.Wonder if you could add another contact block on the 3way switch so the rims would only activate when the bk element is off,

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)