Hans O. Lowe

Well-Known Member

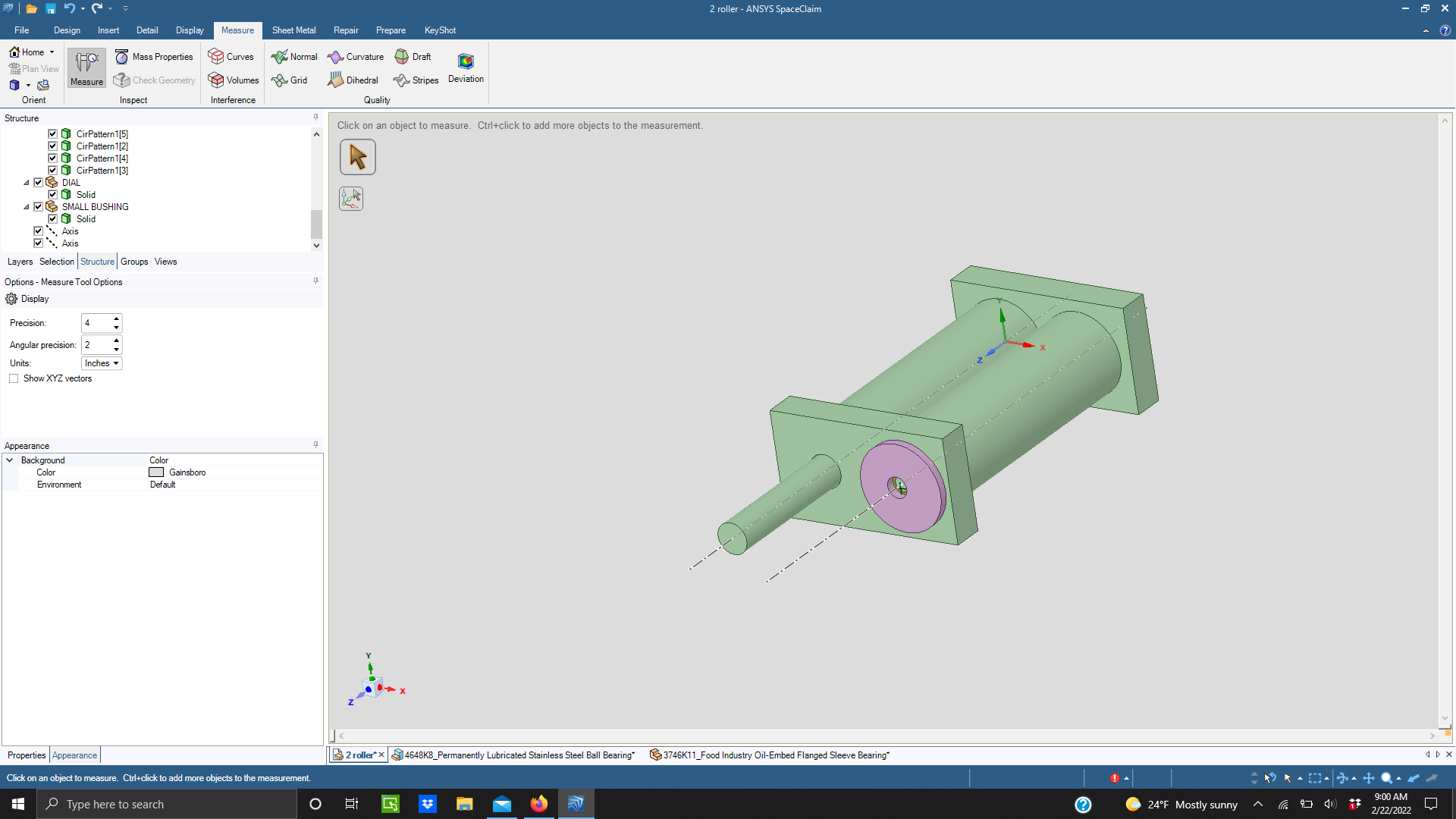

I work for a company doing design, prototyping, and small quantity manufacturing. We've been slow recently and the owner has said a few times we need to diversify. I decided to prototype a heavy-duty grain mill as a possible product to sell. (I don't own one so that's a bonus for me)

If you were adding things to your wish list of what a mill can do and features you'd like to have on one what would they be?

If you were adding things to your wish list of what a mill can do and features you'd like to have on one what would they be?

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)