stpug

Well-Known Member

- Joined

- Nov 5, 2012

- Messages

- 3,808

- Reaction score

- 769

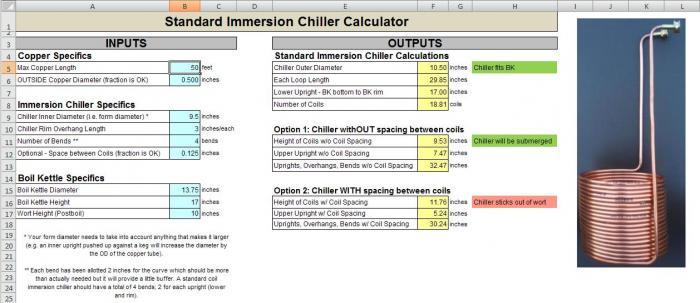

I'm looking at coiling up some copper I recently picked up at the HD clearance sale and thought I'd quickly put something together to help myself dial-in the coil height, uprights, bends, width, etc. I **think** this works fairly well and thought I'd pass it along. If there are any glaring mistakes, please let me know. It's not protected in any way so feel free to make changes as you wish. (I aimed for that all familiar look of Bru'N Water  ).

).

The Excel spreadsheets can be downloaded below (pick whichever format best suits your needs; xls/xlsx). You will need to remove the bsm/bsmx extension so that your computer recognizes them as Excel documents. Sorry, I couldn't figure an easier way to provide them

View attachment ChillerCalculator.xls.bsm

View attachment ChillerCalculator.xlsx.bsmx

The Excel spreadsheets can be downloaded below (pick whichever format best suits your needs; xls/xlsx). You will need to remove the bsm/bsmx extension so that your computer recognizes them as Excel documents. Sorry, I couldn't figure an easier way to provide them

View attachment ChillerCalculator.xls.bsm

View attachment ChillerCalculator.xlsx.bsmx

and was looking for a calculator for my IC build! I have only played with it for a few minutes but so far looks to work very well. My only request would be to have an option for multiple coils, as I plan to build a dual (inner & outer) coil chiller. ie.

and was looking for a calculator for my IC build! I have only played with it for a few minutes but so far looks to work very well. My only request would be to have an option for multiple coils, as I plan to build a dual (inner & outer) coil chiller. ie.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)