There are tables online for freezing temperature vs glycol concentration. Here's one: Glycol-Freeze-Point. From that, it looks like your 30% solution is good to about -13*C (8*F).I was thinking of lowering the reservoir temp but BrewBuilt suggests not to go below -2C. I do have a neoprene jacket around the fermenter and towels on top. So, the 3:1 glycol solution won’t freeze at -5C? It’s a 25% glycol solution. I reached out to MoreBeer, they suggest that I go with a 40% glycol solution

AFAIK, there is are a couple of tradeoffs to glycol ratio: 1) glycol is more viscous than water, so makes the pumps work harder, and 2) water holds more heat (or cold if you prefer) than does pure glycol. Both lead to wanting to use the minimum ratio that gets to your required temperature.

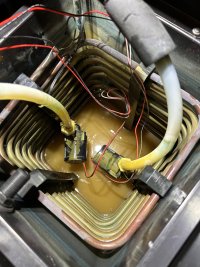

The Icemaster has a little window under the cover where you can shine a flashlight and see if you have accumulated any ice on the evaporator coils. So long as you have no ice, you're good to go. (That's been my practice anyway.)

The coolstix might work with cold enough glycol and enough insulation around the fermenter. -2C seems arbitrary (unless there's a pump limitation?), so with 30% glycol I'd go colder (any maybe double up on a blanket) before doing anything else.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)