I purchased these quick connects: Beer & Gas Quick Connect - In-Line Set (With Shut-Off) | MoreBeer

and this tubing: High Temp Silicone Tubing - 3/8 in. | MoreBeer

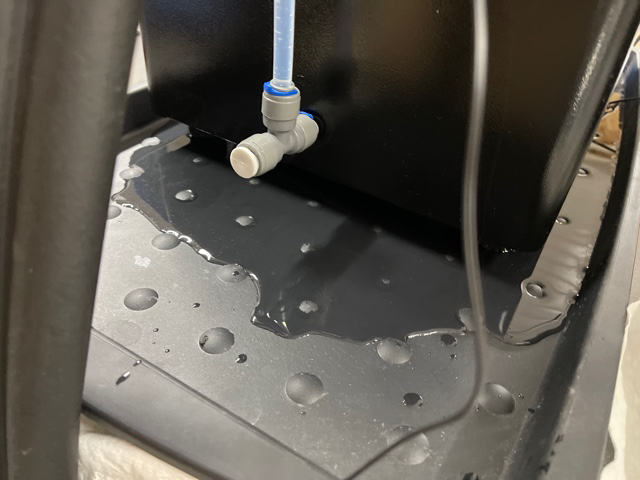

Which clearly didn't go so well because the tubing ID was way to large for the quick disconnects. SO...I'm thinking about buying this tubing: Amazon.com: Pure Silicone Tubing - 1/4" ID x 3/8" OD - High Temp Kink-Free Hose Tube 500F (10 Feet): Home Improvement

Using this smaller tubing INSIDE the larger tubing, along with a clamp, should provide a tight seal. If anyone has a better approach, I'd like to hear it.

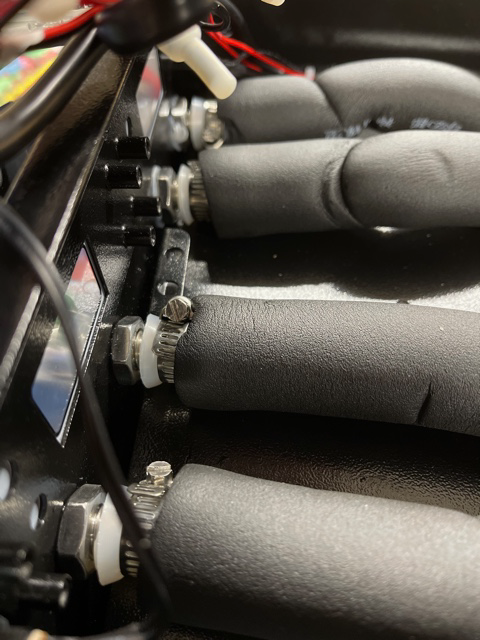

The reason I need these quick disconnects is to disconnect the tubing from the Glycol chiller when moving the Spike CF5 fermenter over to the cleaning station area. The quick disconnects will allow separation without loosing much glycol solution.

This is similar to the dual valve quick disconnect that comes with the SS Brewtech kit. US Plastic also sells them at a slightly higher price but they are OOS.

https://www.freshwatersystems.com/p...pling-body-3-8-id-barb?variant=13249454964779https://www.freshwatersystems.com/p...ing-insert-3-8-id-barb?variant=13249715241003

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)