pizzaman

Well-Known Member

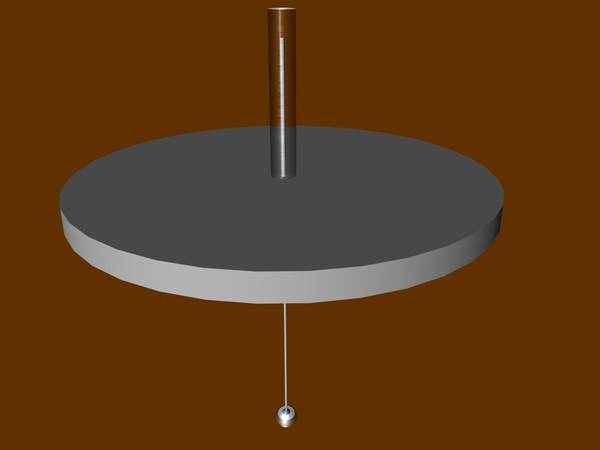

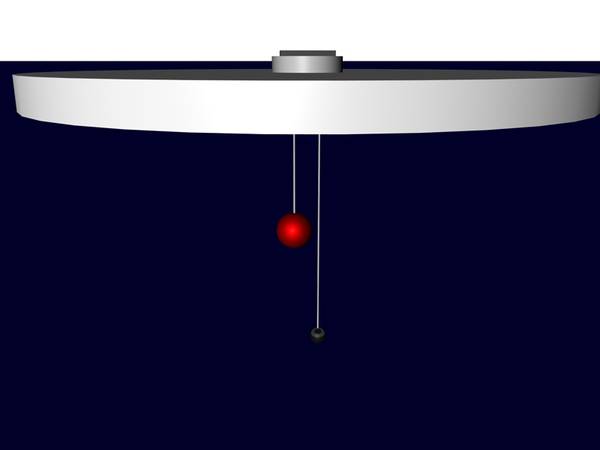

Just had a strange thought whilst sitting on the porcelain lazboy. "Oh how wonderful it would be if I could check the SG of my brews without having to sanitize things, open the lid, risk oxidation, etc." (my thoughts often have an etc. in them)

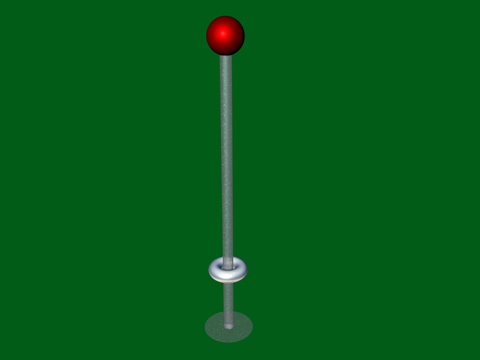

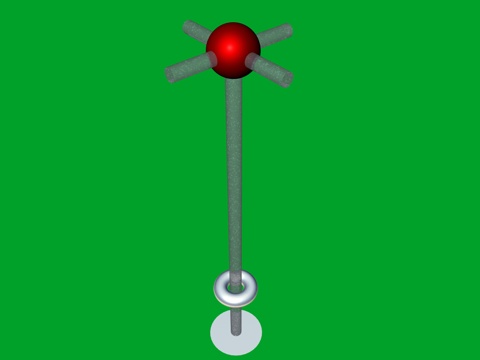

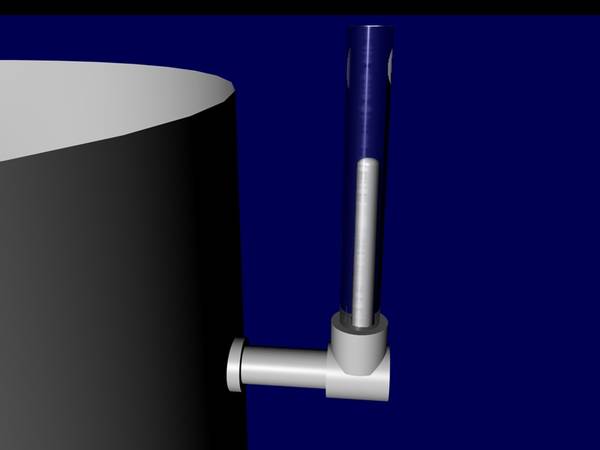

Then it hit me, why not build a carboy with a built in hydrometer attached to the outside. You could get real-time SG readings by simply looking at the hydro-gauge, which I imagine would be very useful for all levels of homebrewers. Since this thought is still fresh in my mind, I only have a few basic ideas about how one would go about doing this. A quick search of the "world wide web" didn't come up with any similar ideas but, has anyone ever heard/thought of anything like this?

Then it hit me, why not build a carboy with a built in hydrometer attached to the outside. You could get real-time SG readings by simply looking at the hydro-gauge, which I imagine would be very useful for all levels of homebrewers. Since this thought is still fresh in my mind, I only have a few basic ideas about how one would go about doing this. A quick search of the "world wide web" didn't come up with any similar ideas but, has anyone ever heard/thought of anything like this?

When I was working in radio I used to get my best ideas for commercial copy while worshipping on the same throne...

When I was working in radio I used to get my best ideas for commercial copy while worshipping on the same throne...

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)