harpo

Well-Known Member

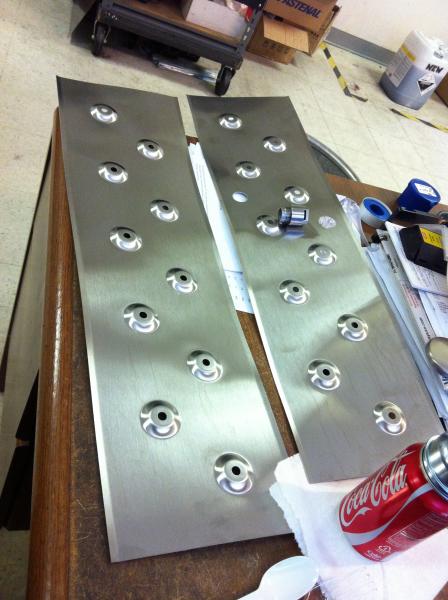

Just finished welding the jacket on. Inlet port is lower, and has a pointed flow of around the keg. Outlet is full open.

Now time to hook up glycol in a chest freezer with a pump and solenoid. We'll see how it goes.

10 gallons is just over the top of the jacket. Should be able to maintain temp as well as crash cool overnight for filtering and carbonating.

Now time to hook up glycol in a chest freezer with a pump and solenoid. We'll see how it goes.

10 gallons is just over the top of the jacket. Should be able to maintain temp as well as crash cool overnight for filtering and carbonating.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)