DuncB

Well-Known Member

It's called cellar temperature.Imagine a world with nothing but warm beer.

It's called cellar temperature.Imagine a world with nothing but warm beer.

One could get a rough idea by looking at the "back panel" ratings on the fan.

~4.8W for this one, provided run at the full 24V

So where I live, about 87 degrees. Maybe I should invest in sake.It's called cellar temperature.

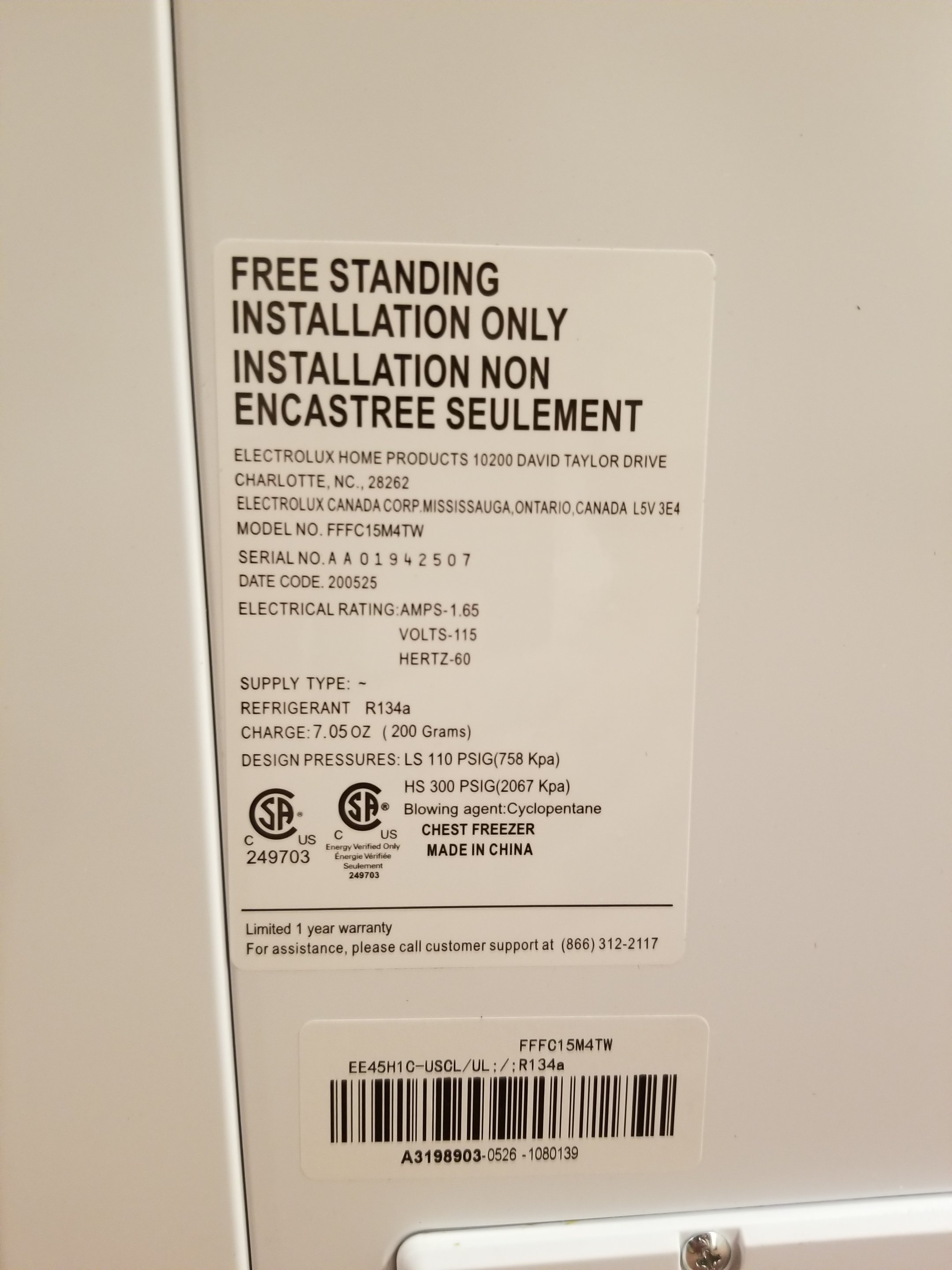

More great news: R134a is being phased out because of the ozone layer. It's already banned in cars. Wonder what they'll replace it with. Wasn't ozone the big issue with good old freon? I guess R134a makes smaller holes or something.

it's basically LP and is flammable if it leaks out. Works great however!

Maybe I'll measure it too.

I remember seeing that word on one of my freezers, on a label I tore off in contempt without reading it.Cyclopentane?

Sure, you can, but unless cooling capability is quite limited I'll opine it's not going to change much.

While a higher temp rise may be indicative, I suggest the net BTU working against cooling in either case is pretty small in the big picture.

I remember seeing that word on one of my freezers, on a label I tore off in contempt without reading it.

So they're using a refrigerant gas to pump up foam, but something else in the compressor?

Top marks from me! That's exactly the kind of jury-rigging I love to see.Here is what I did. It runs full time when the controller has power. Just a computer fan taped to a duct elbow, so it pulls cold air from the bottom of the freezer and blows it up. The orange thing is an oil pan heater that the fan blows over when the controller is heating the chamber. I should probably put a screen over the open end, but I haven't had a problem yet.

View attachment 839165

Do you get any notable differences in compressor cycle times between the probe as pictured to when it's plugged into a fermenter-probe?Note that there's a quick disconnect on the temperature probe. I have NTC 10K probes permanently mounted in all of my fermentors, I just plug them in when I have them in the keezer so the temperature control is on liquid temperature.

Never really paid much attention to cycle times. It just maintains a more stable liquid temperature.Do you get any notable differences in compressor cycle times between the probe as pictured to when it's plugged into a fermenter-probe?

Do you get any notable differences in compressor cycle times between the probe as pictured to when it's plugged into a fermenter-probe?

You do have to set the controller to lower tolerances when you're controlling by liquid temperature reading. I use a 2° spread for liquid in a 3° spread for air/ambient.Years back I posted some traces of temperatures I recorded with some datalogging equipment. Unfortunately those images seem to be gone and I can't find the originals.

As I recall, the cycle times did vary between air temp and immersion or insulated surface temp. But, as one might guess, the liquid temp didn't swing much at all because of the relatively large mass.

Maybe I'll record all that again one day, if for no other reason than just because.

A blob of blu tack and then the microfoam pad held on with a bungee cord seems to work well on my fermenters.I like to tape/tie/rubberband the temp probe to the lower part of a keg, maybe with a little foam over it.

Yep, it’s what I do in my keezer.I like to tape/tie/rubberband the temp probe to the lower part of a keg, maybe with a little foam over it.