madscientist451

Well-Known Member

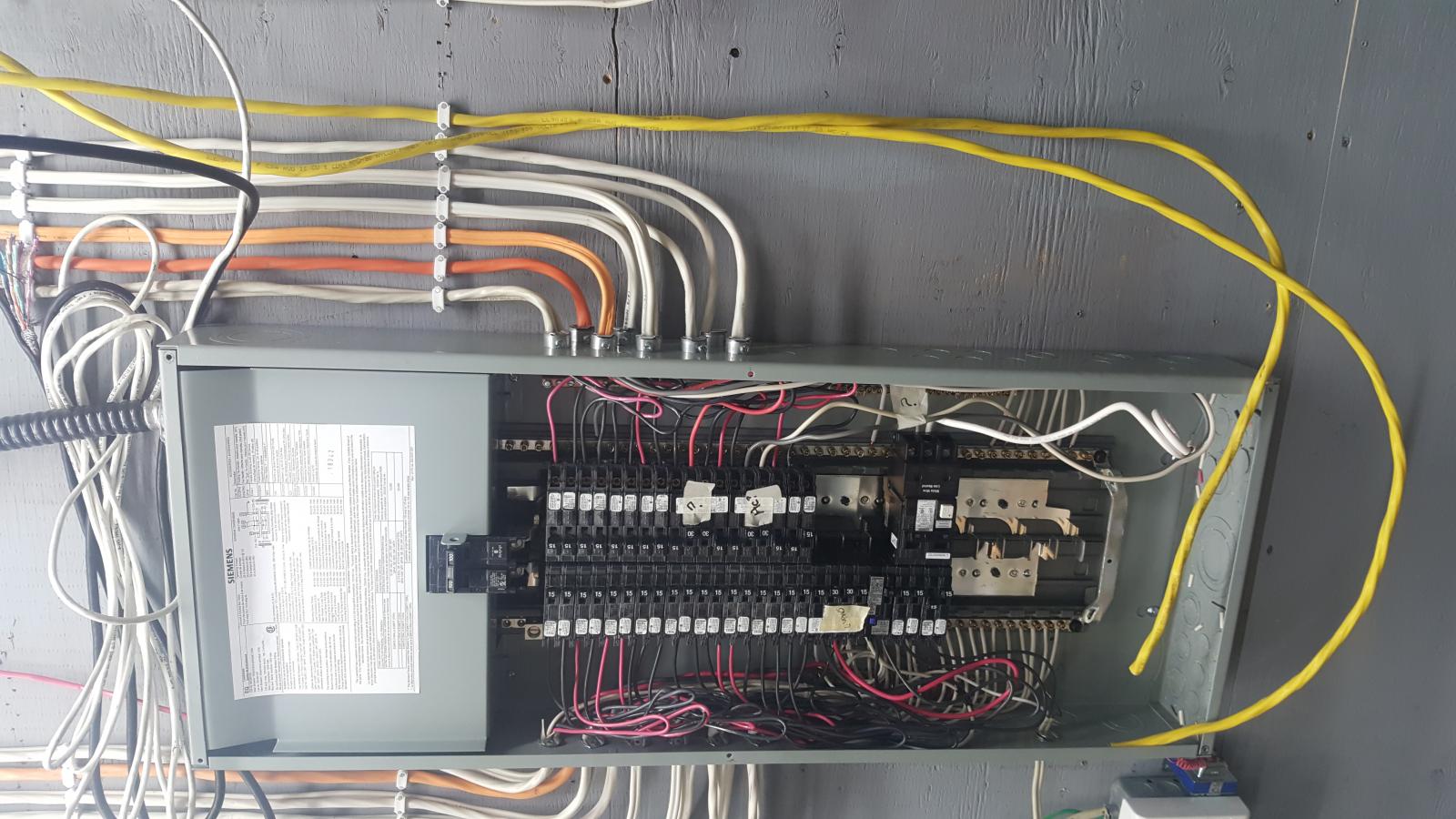

Hey "buddy", I asked you what size and type wire you have coming from the pole to your meter and from the meter to the panel and you didn't answer....Here are some more facts:

Around here, the electrical code is written in to law. Any activity that circumvents the permit process or intentionally violates the electrical code is also a violation of the law.

In your state, maybe its different, I don't know.

You also stated that the meter is designed for 100 amp and since you may be pulling a higher load now it isn't reading the actual consumption properly, so that sounds like a theft of electricity. The power company people around here are inflexible A-holes. I hope, for your sake, that they are a little more easy going in your area.

Around here, the electrical code is written in to law. Any activity that circumvents the permit process or intentionally violates the electrical code is also a violation of the law.

In your state, maybe its different, I don't know.

You also stated that the meter is designed for 100 amp and since you may be pulling a higher load now it isn't reading the actual consumption properly, so that sounds like a theft of electricity. The power company people around here are inflexible A-holes. I hope, for your sake, that they are a little more easy going in your area.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)