kal

Well-Known Member

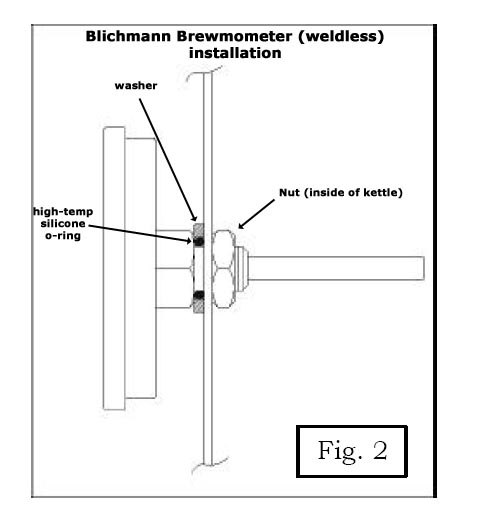

Yup, metal on metal is not good, but take a look at the picture I posted above from the Blichmann manual on how it works. It's not metal on metal:

Maybe it's just me then but I really like the way Blichmann does it as it makes sure you don't overtighter the nut. You could throw an extra washer on the inside but I don't think it's probably needed.

BTW, I emailed John Blichmann last night and I already had an email this morning indicating that he'd update the next print run of their Boilermaker and Brewmometer manuals to include more labels like my Figure 2 above (to make it clearer for people what's what). I've always been impressed with their service. 5 thumbs up!

Kal

Maybe it's just me then but I really like the way Blichmann does it as it makes sure you don't overtighter the nut. You could throw an extra washer on the inside but I don't think it's probably needed.

BTW, I emailed John Blichmann last night and I already had an email this morning indicating that he'd update the next print run of their Boilermaker and Brewmometer manuals to include more labels like my Figure 2 above (to make it clearer for people what's what). I've always been impressed with their service. 5 thumbs up!

Kal

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)