This is not really true, as I have used both gas and electric systems. My electric systems have kicked the pants off my gas systems for boiling.

9000W is equal to 30,708 BTUs... BUT it heats 3x faster than my little 55K BTU propane burner.

I dont know how else to design a gas system aside from proper shielding, so that it helps to concentrate the heat at the kettle.

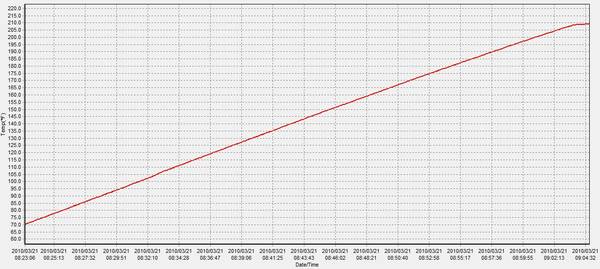

9000W will take 13 gallons from sparge temp. 160F to a boil in 11 minutes. I could never get close to this with my gas burners, I couldn't do it that quickly in a 7 gallon boil in fact. I can also heat 5 gallons of strike water at a rate of 10F per MINUTE. I dont understand the brute force analogy, because this seems like brute force to me.

I know people like to say that electric is slow, but it isnt when you consider that it is about 95% eff (accounting for heat loss) and it has been tested time and time again with gas burners and the numbers are anywhere from 20-30% eff. This means that you need a gas burner that is 3-5x larger than is electric counterpart to heat in the same amount of time.

Even a 5500W BK is equal to a gas burner of about 75K BTUs... it is just much cheaper to operate.

I would put my electric BK against most gas BKs any day.

My garage used to get up to about 90F in the dead of winter when I had a gas BK running. With electric it is still a balmy 45F when the BK is running, because all of that heat is going into the garage, not my boil.

We are wayyyy OT here though and re-hashing the same thing that has always been hashed. Gas users swear electric is slow to heat, and electric users who have used both, know it isnt true, the heating times speak for themselves.

To each their own, but the correct information should be out there

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)