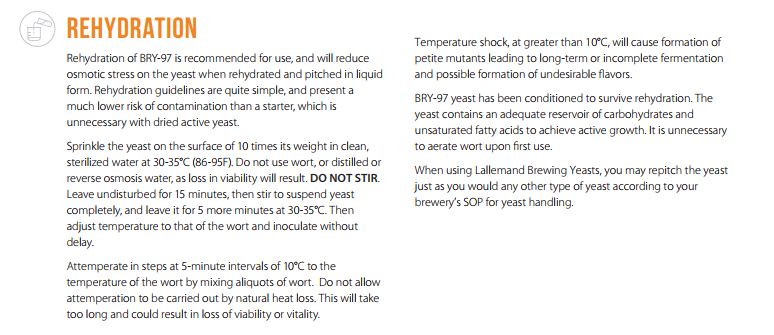

Hey peeps. Brewed a session ale yesterday, about 27-28 hours ago. OG was 1.041 and pitched a packet of danstar bry-97 dry yeast. I did rehydrate the yeast in 100 ml of distilled water heated to 110*F and let it cool. By the time i sprinkled the yeast in the heated water it was about 87*F. I let it rehydrate for 20 min, gently stirred and pitched in carboy. I realized after pitching i didn't shake the carboy first (to aerate) but i did have to pour the wort through a strainer to remove the whole leaf hops i used so i figured that would have aerated enough.

As of right now, there is no sign of fermentation. No movement of particles in liquid, no air lock activity, no krausen, no nothing. My question is how long do i wait before i pitch more yeast? And if nothing starts, is pitching more yeast my solution?

Thanks guys.

As of right now, there is no sign of fermentation. No movement of particles in liquid, no air lock activity, no krausen, no nothing. My question is how long do i wait before i pitch more yeast? And if nothing starts, is pitching more yeast my solution?

Thanks guys.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)