You'd need a bigger vessel to sparge...

"Dunk sparging" is probably the most common procedure for sparging BIAB bags. I'm not sure what kind of vessels brewers use. A larger sparge kettle? Larger, 8-10 gallon bucket, if they exist? A large tub?

Once you start using your new mash tun, (batch) sparging becomes so easy, and virtually mess free.

A few hints:

For 5 gallon, 1.060-1.066 OG batches I mash 12-13 pounds of grist at a thickness of around

1.5 quarts per pound. That mash thickness has been working best for me, any thicker and I get mixing/conversion/temp drop issues. That comes out at around 5 gallons of strike water for the mash, for that target OG.

I then split the remainder of the water into 2 equal volumes, around 2.2 gallons per sparge, doing 2 consecutive sparges. The exact volume used for each batch sparge cycle is not super critical, but you want them to be close for best efficiency.

I do regular vorlaufing to get reasonably clear wort without grain bits. Then fully drain the tun each time, before adding the next volume of water. Good stirring after adding each water addition is needed to "knock" the sugars out of the grain bits, and into solution.

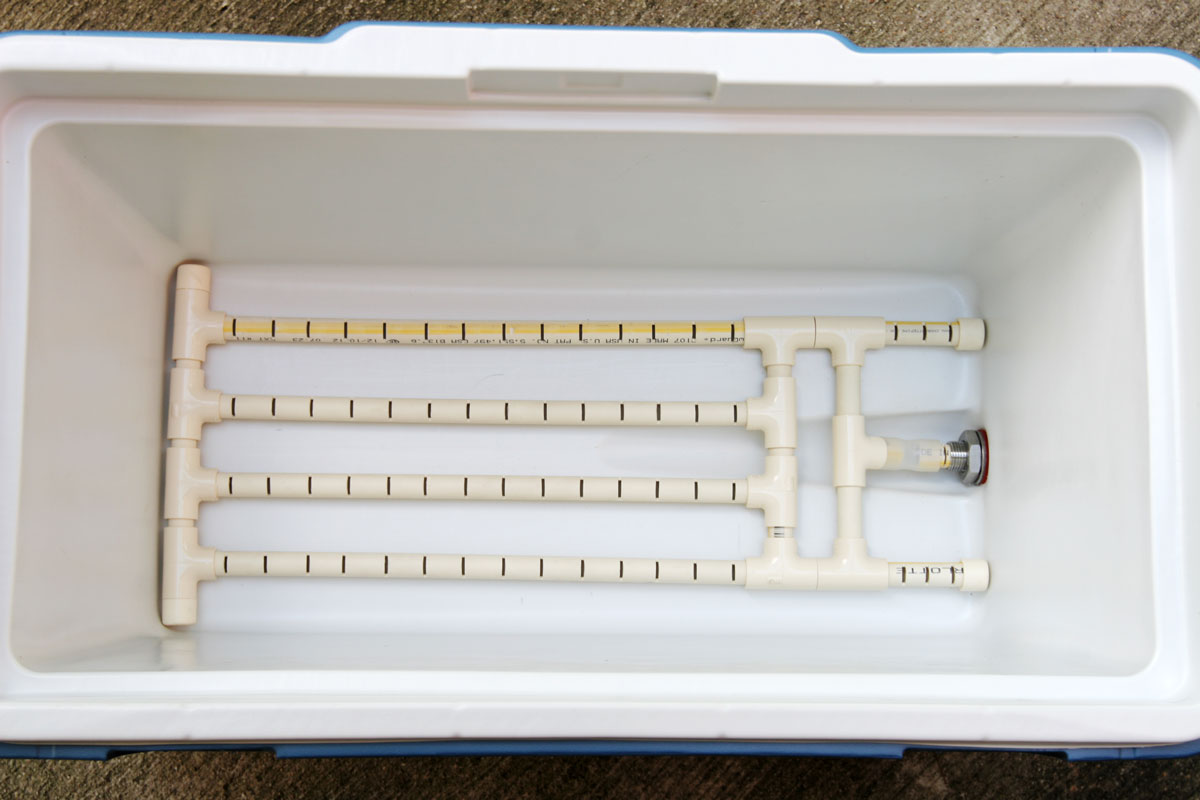

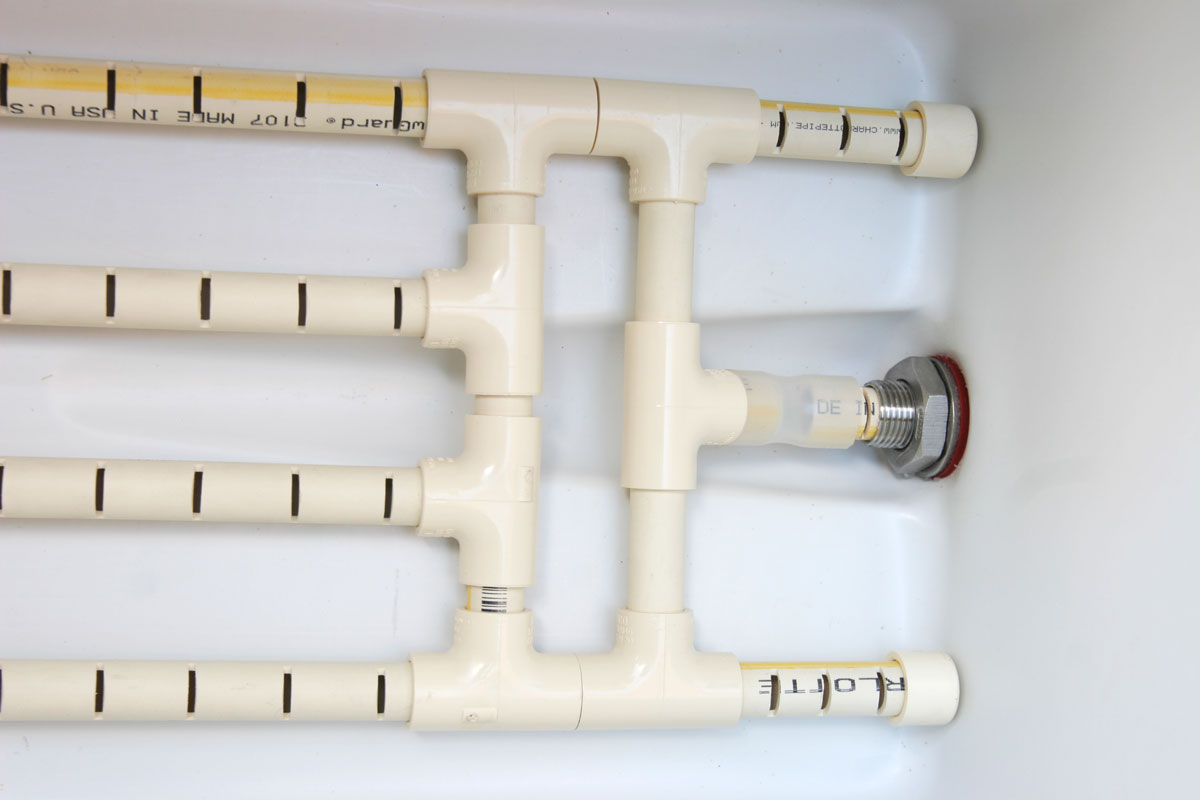

My mash tun is a converted rectangular 54 quart (13.5 gallon) Coleman

Extreme cooler, which drains completely due to the drain opening being recessed in the bottom. I chose for making a manifold (shown

upside down in the pictures, for illustration). But a bazooka tube or stainless braid would work just as fine too.

View attachment 784468

View attachment 784469

Although it's not all that critical, as long as it's not a huge volume, you may need to tilt your round tun toward the exit valve at the end of the lauter to more completely drain it. It depends on how the high the spigot hole is on the inside and how well you can keep the siphon going while draining.

Instead of pouring the grist into the preheated strike water, I fill the (dry) mash tun with (milled) grist. Then

underlet it with preheated (and mineral treated) strike water from the boil kettle.*

Underletting the grist is an effort to reduce O2 take-up.

I'm working on building a better "mash cover." Aside from reducing heat loss to the head space, it also helps to reduce the grist's oxygen take-up.

* You'll need to calculate the temp of your strike water, taking the weight and temp of your grist into account, as well as temp losses to the mash tun and air/environment while mashing in. Most programs like BeerSmith, Brewfather, Brewers Friend, etc. can do most of the calcs for you.

For reference , since I'm underletting, and thus can't effectively preheat my mash tun, for ~13 pounds of 68F grist, I end up heating 5 gallons of strike water to a temp of 178F to hit a mash temp of 154F pretty much on the nose. This is after completely stirring/mixing, putting the mash cover and lid on, and letting the mash settle for about 5 minutes. Then the mash proceeds for a total of 60'.

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)