Thanks for the info. I'll check around with a few of my past HVAC patients to see if they have anything laying around. Unfortunately my HVAC contractor that did my house committed suicide a couple of years back and they dissolved the company after that. Did the older style furnaces have large pulleys....like 12 inchers? I would hate to blow $38 on one pulley if someone has one in a scrap pile.

I have one in my garage with the entire squirrel cage blower that has a 14" pulley on the fan and a 1.5" pulley on the motor. Came from an old Reliance AutoGas furnace. Lots of these should end up at the junk yard after salvage of copper from motor windings.

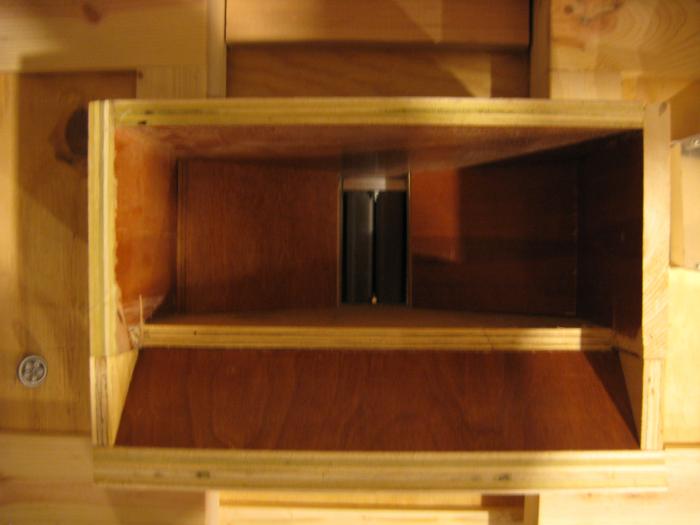

Great job on the design and construction of your equipment. I'm afraid to let my wife see your pictures, she'll make fun of my amateur construction. At least mine is all kept in the garage/workshop area.

I just contacted an HVAC business here in town and they come across these older systems all of the time, but currently don't have any laying around. They took down my name and number and stated that they likely will come across something in the next week or two. I am in need of a quote for a hydronics system to heat my basement floors, so I killed two birds with one stone and they are coming out to quote a system as soon as I get back from vacation. I'm going to take your advice and call a few more places and maybe a couple of salvage yards. Thanks again!

I just contacted an HVAC business here in town and they come across these older systems all of the time, but currently don't have any laying around. They took down my name and number and stated that they likely will come across something in the next week or two. I am in need of a quote for a hydronics system to heat my basement floors, so I killed two birds with one stone and they are coming out to quote a system as soon as I get back from vacation. I'm going to take your advice and call a few more places and maybe a couple of salvage yards. Thanks again!

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)

I have always been the type of person that has a hard time sitting idle and am in constant need of projects to keep me busy. Once I started homebrewing and realized the endless array of potential projects associated with advancing in the craft, it was a match made in heaven for me and I've went at it full bore. Yes, I do have the financial means to tackle these projects, but I am also very economical with how I proceed with them. I have no problem buying used equipment (grain mill, ss brewing table, ss prep. table, ss commercial sink, brewery fixtures, chest freezers, decommissioned sanke kegs, etc.), fabricating my own equipment, and anytime I can recycle old lumber or materials, I do. I rarely purchase anything brand new, so I'm able to complete these projects at a fraction of the cost. I'm like a bloodhound on CL, so if there is something I need for a brewing related project and it's out there, I'll find it. It doesn't take an unlimited supply of cash to build some really nice equipment, if you are ambitious and patient.

I have always been the type of person that has a hard time sitting idle and am in constant need of projects to keep me busy. Once I started homebrewing and realized the endless array of potential projects associated with advancing in the craft, it was a match made in heaven for me and I've went at it full bore. Yes, I do have the financial means to tackle these projects, but I am also very economical with how I proceed with them. I have no problem buying used equipment (grain mill, ss brewing table, ss prep. table, ss commercial sink, brewery fixtures, chest freezers, decommissioned sanke kegs, etc.), fabricating my own equipment, and anytime I can recycle old lumber or materials, I do. I rarely purchase anything brand new, so I'm able to complete these projects at a fraction of the cost. I'm like a bloodhound on CL, so if there is something I need for a brewing related project and it's out there, I'll find it. It doesn't take an unlimited supply of cash to build some really nice equipment, if you are ambitious and patient.