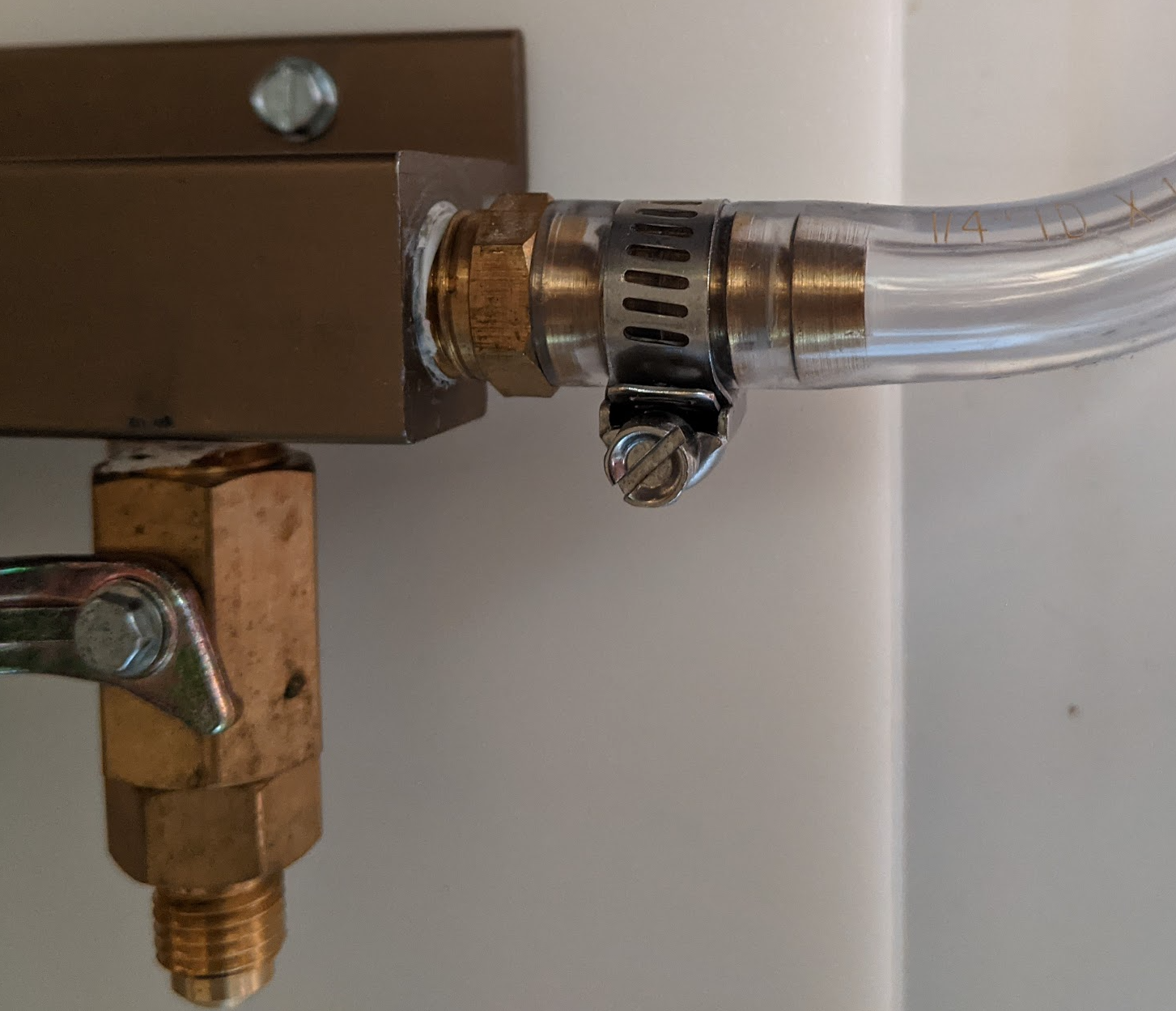

I realized my CO2 manifold already has flare fittings, so I'm making the switch to EVABarrier.

However, the manifold input is a 5/16" barb, as is the output barb on the reg.

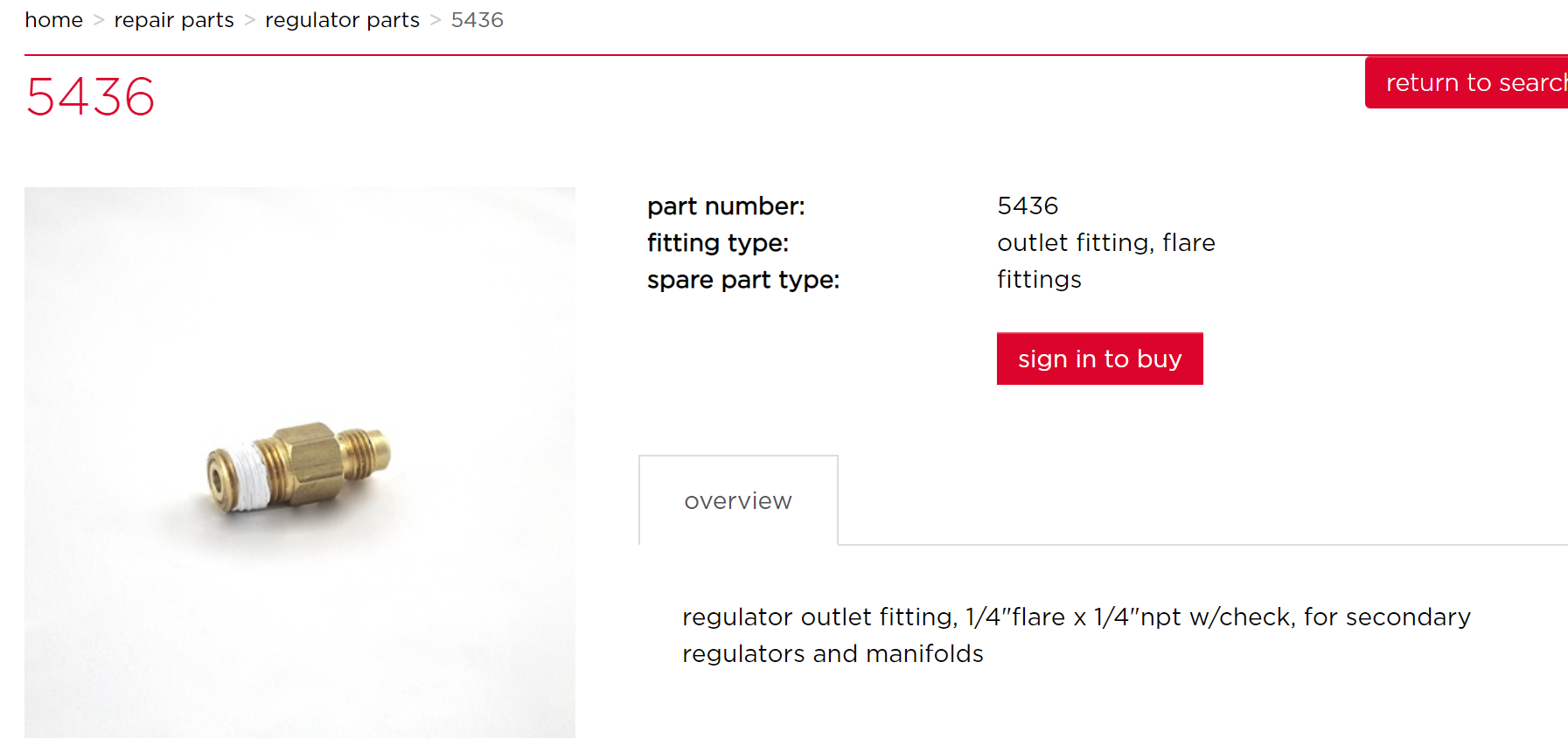

What's the best way to get DuoTight fittings in these spots? Can I just unscrew the barbs and replace them with this? Somehow the non-flare side doesn't look quite right though.

Same thing without check valve appears to be here: Brass Flare Fitting - 1/4 in. Flare x 1/4 in. MPT | MoreBeer

And, if I got an adapter that did not come with sealant, what should I use? I see regulators assembled with both Teflon tape and the dried up liquid sealant.

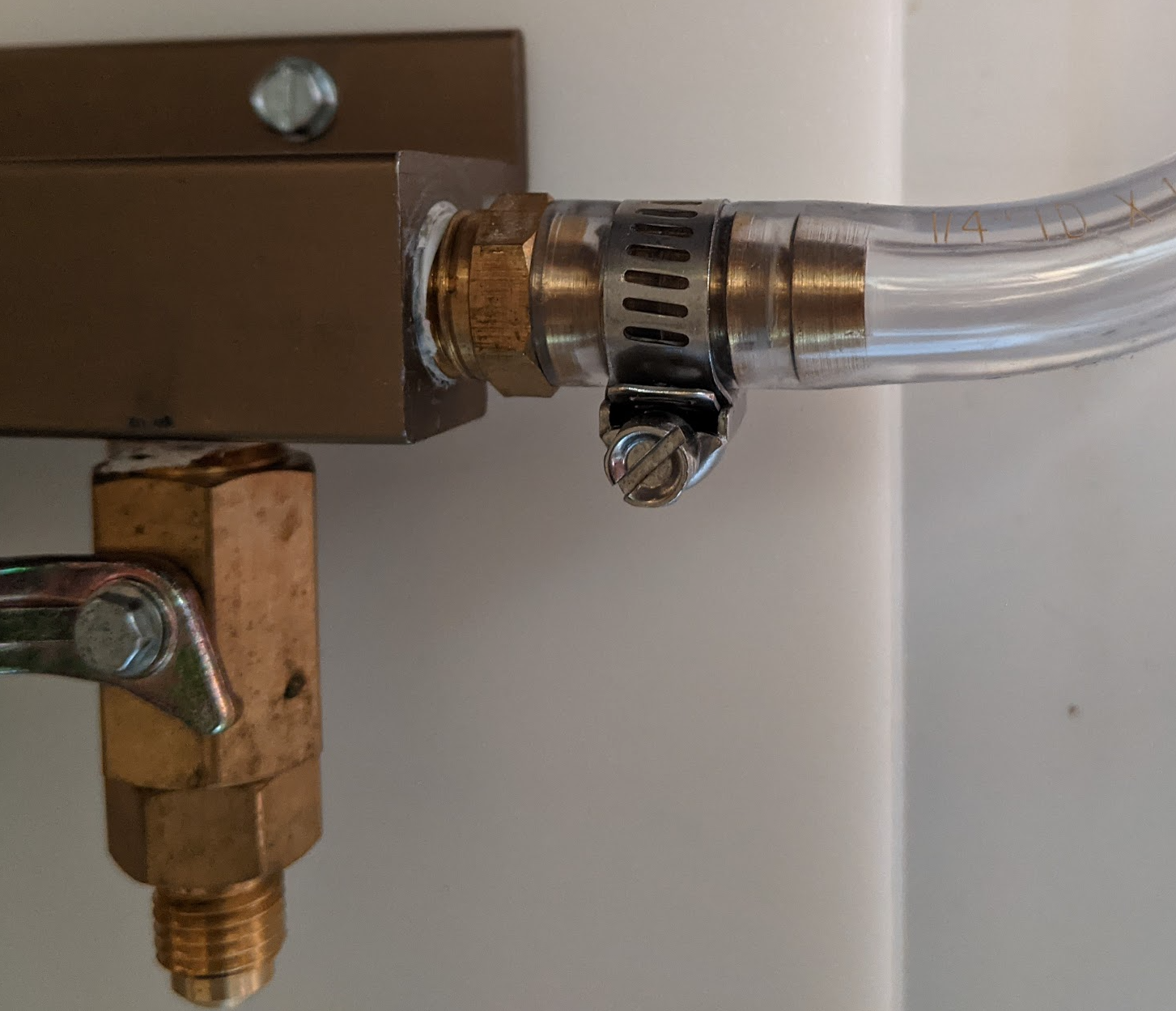

However, the manifold input is a 5/16" barb, as is the output barb on the reg.

What's the best way to get DuoTight fittings in these spots? Can I just unscrew the barbs and replace them with this? Somehow the non-flare side doesn't look quite right though.

Same thing without check valve appears to be here: Brass Flare Fitting - 1/4 in. Flare x 1/4 in. MPT | MoreBeer

And, if I got an adapter that did not come with sealant, what should I use? I see regulators assembled with both Teflon tape and the dried up liquid sealant.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)