marcb

Well-Known Member

Big_Cat said:How many 5 Gallon buckets did you use?

No idea, another HBT member referred me to a flooring company and I used them.

Big_Cat said:How many 5 Gallon buckets did you use?

marcb said:No idea, another HBT member referred me to a flooring company and I used them.

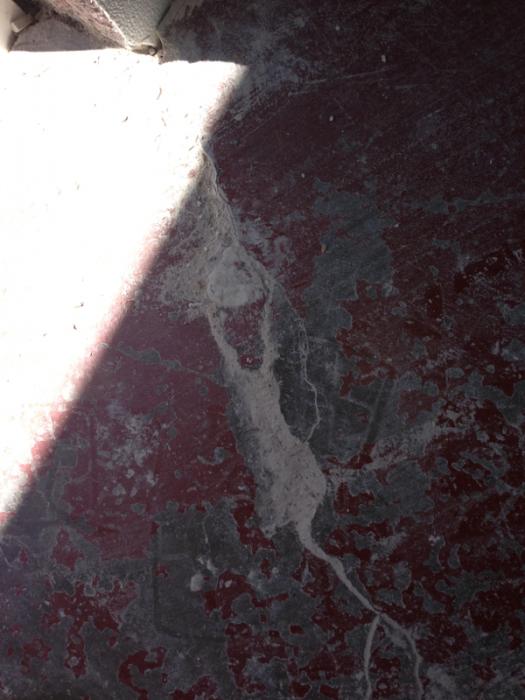

Went from pic1 and 2 to this:

Pic3

Eh. Whatever. It's just a floor.

Kidding, it really looked great when I saw the prime coat the other day.

Marc, I've been busy again. Between the $80 I spent at Santa Clara liquors the other day and the visits to the Davis beer shoppe and university of beer I'd say we have quite a selection for tasting this week. Give swmbo our best for mamas day, ill bring the kettles over one day this week.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

Carlscan26 said:So did they open the rollup door a foot or so and fill the space with insulation? Was that to allow air flow but to keep the dust and such out? Did they shove the insulation in or is there a frame involved too?

marcb said:Will post pics tomorrow as there isn't any light out in the garage yet! Paint and trim finished today, sink is in! Floor touch up, plumbing and electrical should all be stitched up tomorrow.... Or thereabouts. It looks great but more importantly I now get to get back on track with my build!!!!!!!!

I'm pretty pleased with all the progress so far!

MooMooBrew said:Got a question about the cold room, how much insulation did you use and is there a vapor barrier installed, i didn't see one in the pictures.

MooMooBrew said:Got a question about the cold room, how much insulation did you use and is there a vapor barrier installed, i didn't see one in the pictures.

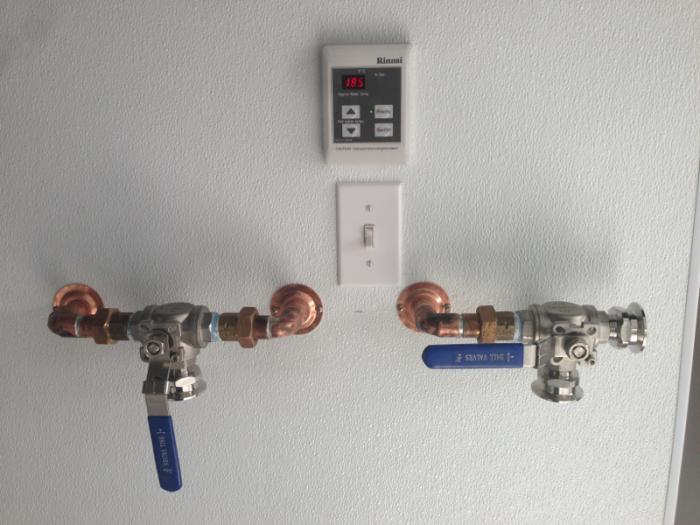

Tankless is live and generates 185 degree water full throttle! Amazing!

barryfine said:That's a sweet setup! Where is the tankless located? Is it an electric, gas, or propane model?

Forgive me if I've missed it, but what are the ventilation specs, ie. fan cfm/type, duct diameter, etc?

Tankless is live and generates 185 degree water full throttle! Amazing!

DrPhilGood said:Is one of the outlets the cold water and the other the hot water?

P.s. what is the flow rate at 185 degrees?

Chamuco said:Amazing progress Marc!