Austin_

Well-Known Member

What size Wilsner bag do you have?

Apparently, there are two types of stainless steel baskets we're talking about. One is a fine mesh basket and the original HG basket that has rows and rows of 7/16 inch diameter holes in it. I have the original basket and have to use a fine mesh grain bag inside it to filter the grains.

Are we 100% sure that our grain bags won't burn through it they sit on top of a 5,000-watt heating element?

I'm guessing mine is not really a custom size but I have a 15 gallon pot and I gave him the dimensions of my pot, not the basket in case I every decided not to use the basket. I think I paid $22 for my bag if I remember right.What size Wilsner bag do you have?

So I have the BrewBuilt 15 gallon version of this as I mentioned before and it doesn't ship with a pickup tube. I have an SS Brewtech Trub Dam but not sure what I need to allow the press fitting to work. The port allows for any accessory that features 1/2" MPT threads. I can't find any info on the Trub Dam dimensions.

Your best bet is to email Ss Brewtech and ask about their bulkhead that comes with their kettles and ball valves. The thing you need is a their proprietary weldless bulkhead fitting (not the FTP one). I can't find it in their online shop so I'm not sure they sell it separate from their kettles.

If you scroll down the page here:

https://www.ssbrewtech.com/pages/kettle

and look at what comes in the box. It's that bulkhead fitting that you need.

Shoot a support email in and see, never hurts to ask.I'm afraid you are probably right. From one of their FAQ pages they mention that these are not sold separately. Bought it from them but it's marketed as a "replacement".

I have a 15-gallon kettle and clean in place. Right after filling the fermentors and pitching the yeast I clean mine before the wort hardens. Add 3-gallons of water to half a cup of PBW and heat it to 140F. Then let it recirculate for 15 minutes and pump it out through the counterflow chiller. Next, repeat this step omitting the PBW but before pumping it out this time use a long handle brush to remove any shmutz from the heating coil. Follow that with wiping the coils down with a cotton cloth. When done the inside of the kettle and the heating element look like new.How’s your cleaning process so far on the ss brewtech kettles? I’ve got a 20 gal, so a little tough to lift and rinse out. I’ve been using PBW and running it thru the pump for 20 min with cold water, but still have buildup and gunk on the coils. Next time I’m goin to heat the water while it’s running thru the cleaning cycle...

How’s your cleaning process so far on the ss brewtech kettles? I’ve got a 20 gal, so a little tough to lift and rinse out. I’ve been using PBW and running it thru the pump for 20 min with cold water, but still have buildup and gunk on the coils. Next time I’m goin to heat the water while it’s running thru the cleaning cycle...

I use these to clean my Boilcoils:

https://www.amazon.com/gp/product/B000BAT8PM/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&th=1

I cut them in half/quarters and I've only gone through a couple of pads in ~6 months. Just a quick wipe down after cleaning, followed by one more rinse before drying it all off. Worth the $12.

My wife has caught wind of these too and has stolen a bunch for around the house.

I love that brew cart!

Why didn't you ask Dave to get the pickup tube and whirlpool arm for you? He's extremely reasonable with stuff like that.

I agree with ScrewyBrewer that stirring is the key to a better efficiency. Even before I went electric but still doing BIAB, I made sure to stir at least every 12-15 minutes.

I guess the next logical place to look would be your grain crush and stirring the mash. Our systems don't have arms that turn to agitate and keep the grains from clumping together. I've thought about running the loc-line straight down the center of the grain bed. From the outlet in the top to the bottom of the grain bed. In the hope that the streams of moving wort are enough to agitate the grain bed keeping it nice and loose.

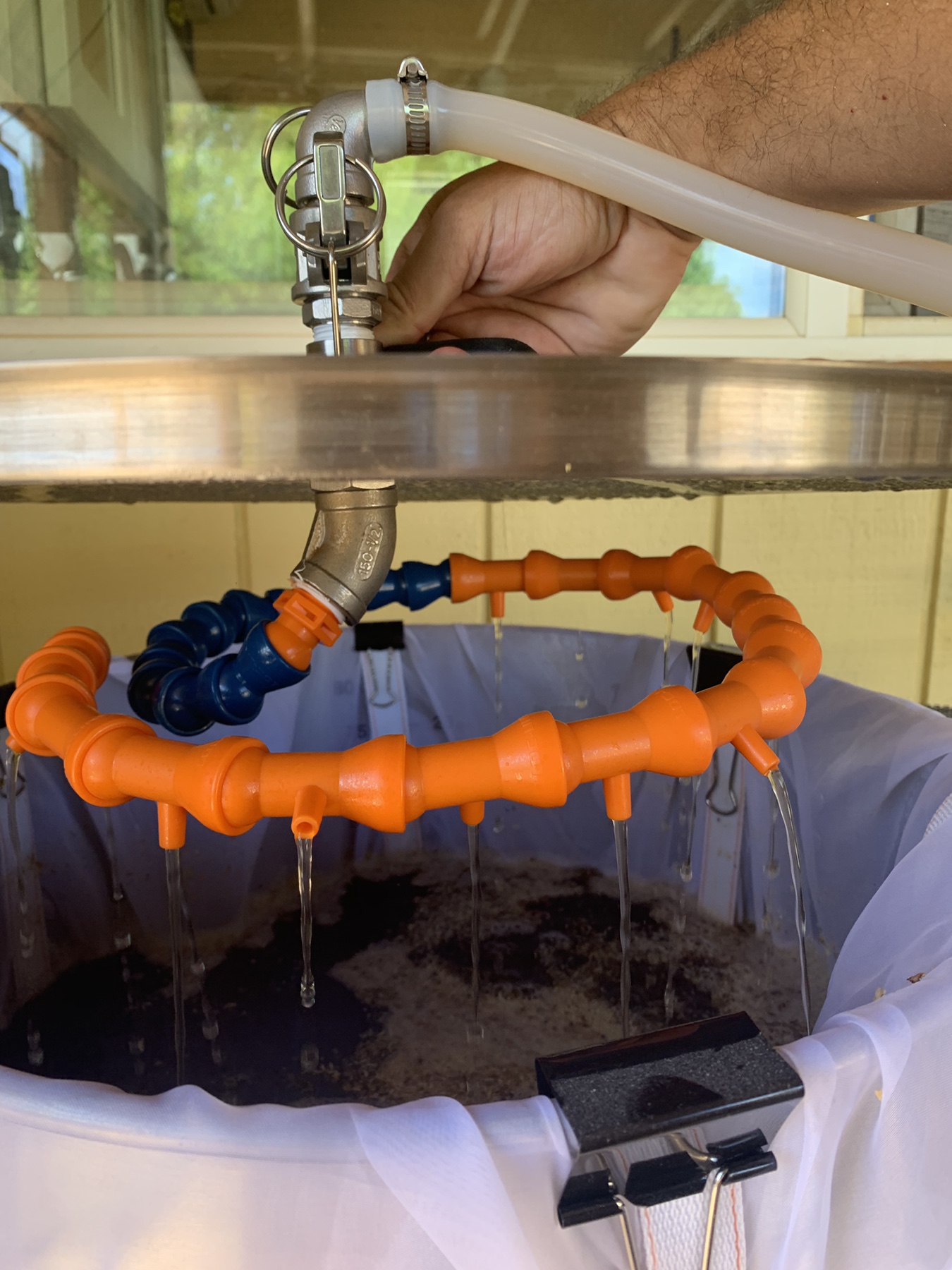

Finally got my whole system together. Wound up getting a pickup tube and whirlpool arm from Brewhardware. I have the 15 gallon 240v version which has the BrewBuilt kettle. The pickup tube fits between two of the coils, touching, but should be fine. I ordered the whirlpool arm with the 18" length and male camlock attachment. Going to test it all tonight and setup my Beersmith equipment profile.

I also put this together last night for a brew cart. It's a beast. Will try to get some pictures of the setup tonight.

Sweet! I love the bar to hold the control unit too!