CaptainCookie

Active Member

- Joined

- Jul 17, 2017

- Messages

- 36

- Reaction score

- 3

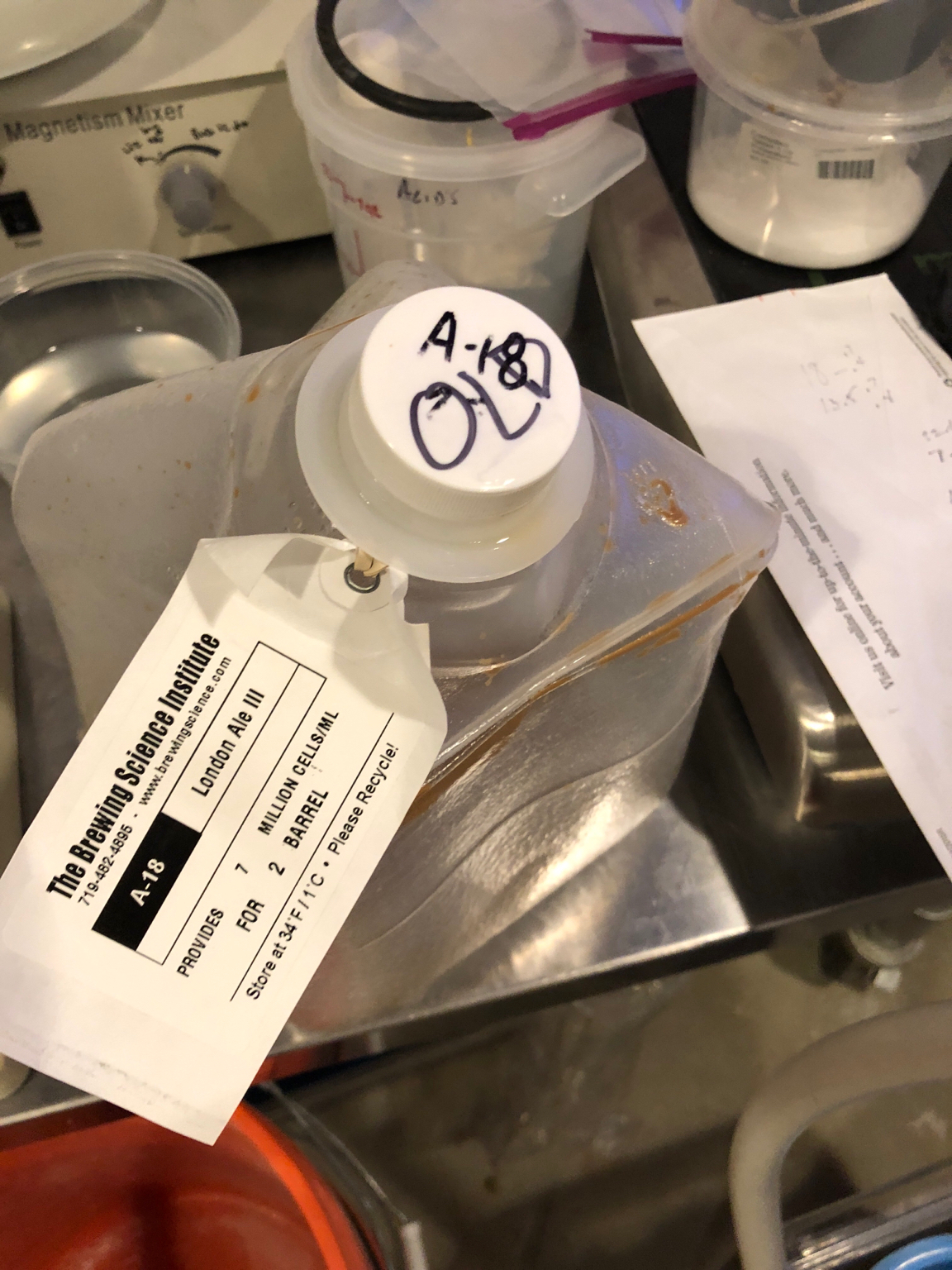

I everyone, so far I've been working only on 5gal carboys, but all the sudden a friend of mine just got a job on a large scale brewery, so he's taking me with him as well, as a helping hand. The brewery works with 1080gal conical fermenters, so they´re looking for someone who can manage yeast starters and viability. I've never worked on so large scale, so I hope you guys can help me with some questions about:

- How are the yeast starters are usually prepared for this kind of volume?

- For a given volume, how much starter is needed?

- For this kind of volume, what percent of viability is needed? how much in yeast's cells is that?

- How do you determinate yeast viability for the starter? please determination by hand, no calculators, so I'll be able to do it by myself on any occasion

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)