JUST_BREW_IT

Well-Known Member

I am an AG brewer that is looking to make the move from propane to electric. I'm wanting to keep things simple for now but leave room for future growth should I choose to do so. I use a 25 gallon aluminum vessel as my brew kettle. I also have a keggle set up as a hlt. I mash in a 150 qt coleman extreme. I have a chugger ss with camlock fittings on everything. I also have both a 50' immersion chiller and a blichman therminator as well. Just to give you a run down of my set up. My typical batches are either 10 or 15 gallons.

Here is my thought process. I have my eye on the 20 gallon version of the boil coil which equates to a 5000W element and requires a 30A breaker which I will be plugging into my dryer outlet in the basement.

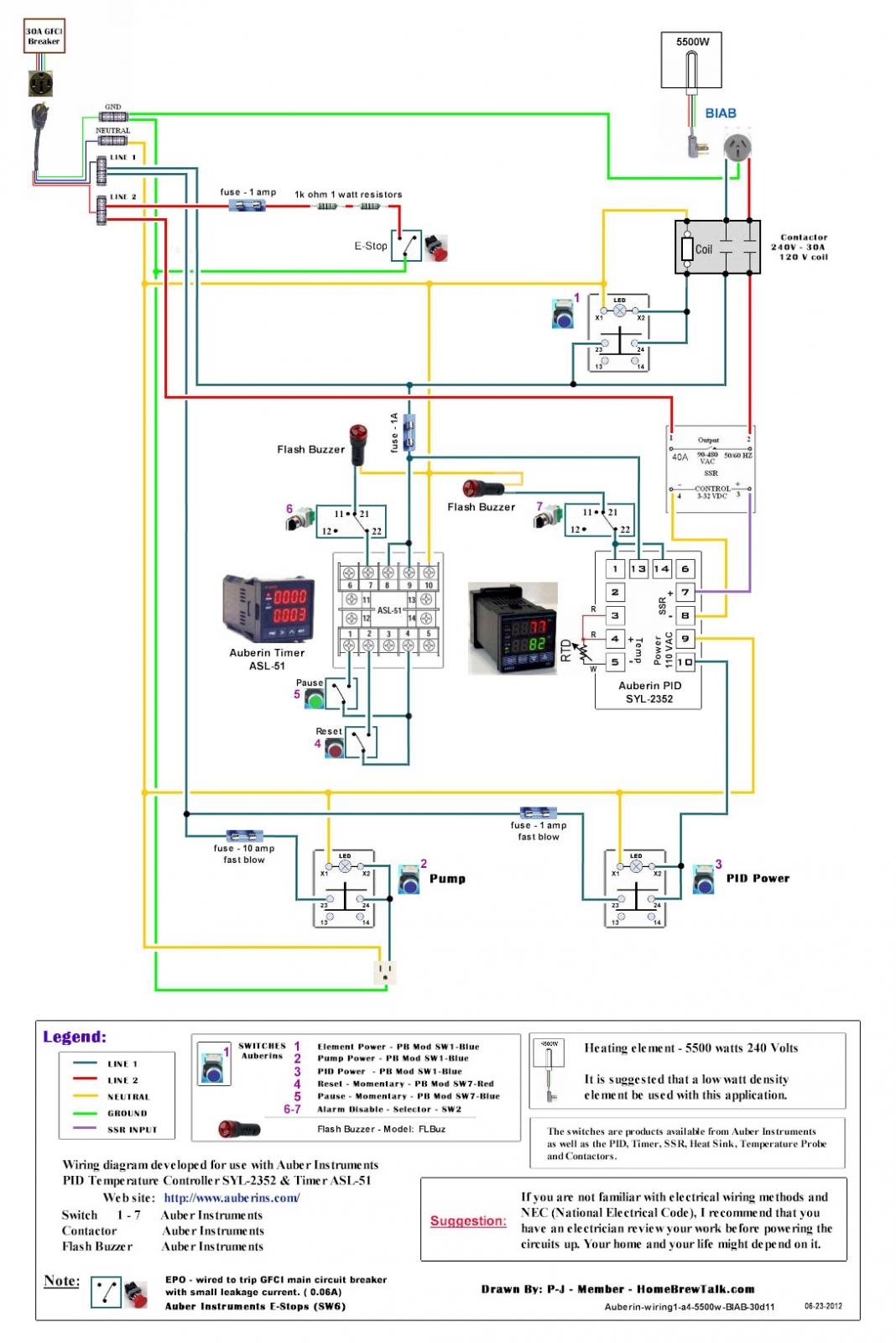

I'm thinking of building a simple controller like this (or have my electrician friend help me). This is a plan developed by hbt member 'P-J' and posted in this thread

Electric Brewers, let me know if you feel this will meet my needs or if I am forgetting anything here.

Thanks in advance!!!

Here is my thought process. I have my eye on the 20 gallon version of the boil coil which equates to a 5000W element and requires a 30A breaker which I will be plugging into my dryer outlet in the basement.

I'm thinking of building a simple controller like this (or have my electrician friend help me). This is a plan developed by hbt member 'P-J' and posted in this thread

Electric Brewers, let me know if you feel this will meet my needs or if I am forgetting anything here.

Thanks in advance!!!