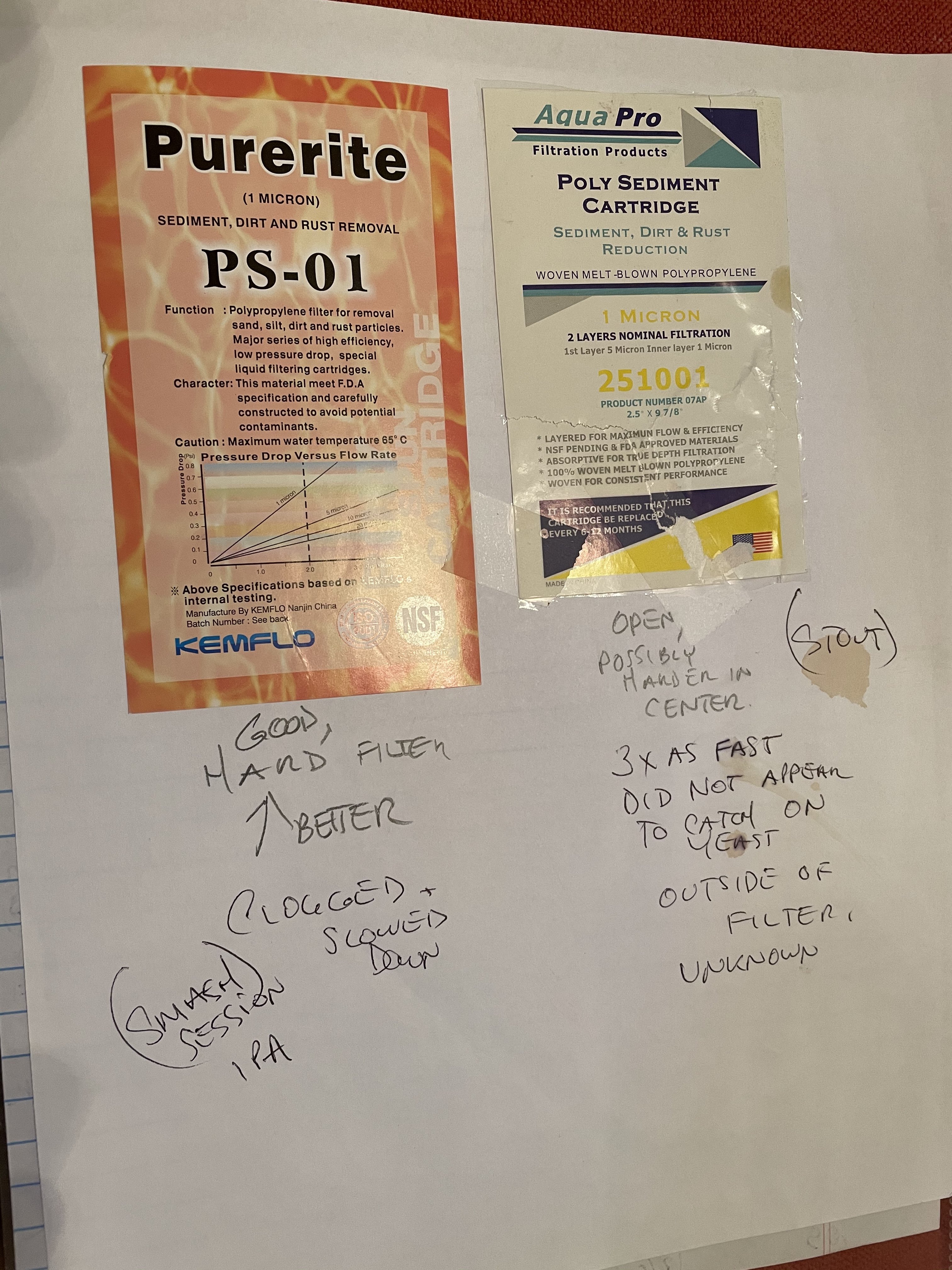

I don’t filter anymore, but when I was filtering I’d lager it in the keg a month or two, do a keg to keg transfer through the filter, then lager it another month. I then force carbonated in the keg, then bottled or placed on tap.

One thing I didn’t mention, usually when on tap, I’ll carbonate to 10 psi. When bottling with a counter pressure filler, I carbonate the keg to 20 psi to account for pressure losses when filling bottles (16 oz flip bottles primarily).

One thing I didn’t mention, usually when on tap, I’ll carbonate to 10 psi. When bottling with a counter pressure filler, I carbonate the keg to 20 psi to account for pressure losses when filling bottles (16 oz flip bottles primarily).

Last edited:

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)