awarner322

Well-Known Member

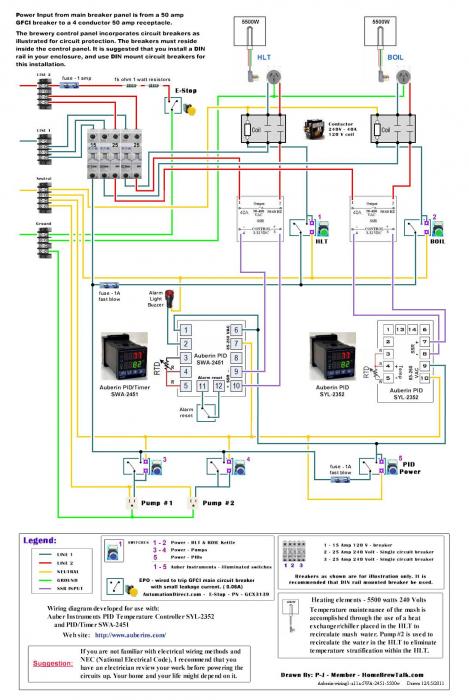

Hey guys, I am struggling with the idea of a heat sink. I am having an electrical engineer buddy put together my control panel for me. It is a 50a 2 element 2 PID system (basically this PJ wiring diagram).

My question now is...what type/size of heat sink do you suggest I get? Do I also need a fan? Does the heat sink need to be mounted internally? or a hole cut in box?

Thanks in advance!

My question now is...what type/size of heat sink do you suggest I get? Do I also need a fan? Does the heat sink need to be mounted internally? or a hole cut in box?

Thanks in advance!

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)