COLObrewer

Well-Known Member

Some interesting reading: http://www.ars.usda.gov/research/publications/publications.htm?seq_no_115=175232 It talks about a specific winter barley cultivar, but it has some interesting general info as well- namely that pretty much all malted barley is from spring barley.

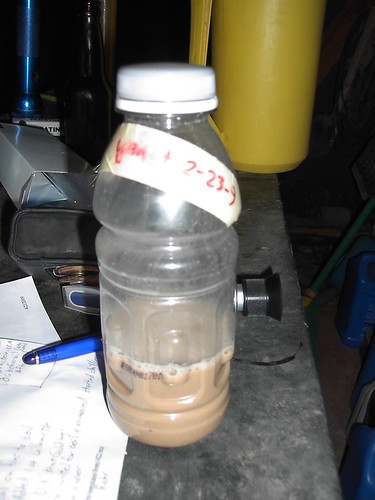

That IS very interesting, looks like it's cultivar 'Charles' for me, but then I would need one of these.

Edited, 03-10: It's amazing how many different cultivars of barley there are, but I guess what would one expect from a grain that's been manipulated by all manner of drunkards for 5000 years or so.

By the way, this helped me figure out why a bunch of my pics were smaller, they should all be regular size now, thanx for all your help guys SHEEESH!

Sweet!!!

Sweet!!!

![Craft A Brew - Safale BE-256 Yeast - Fermentis - Belgian Ale Dry Yeast - For Belgian & Strong Ales - Ingredients for Home Brewing - Beer Making Supplies - [3 Pack]](https://m.media-amazon.com/images/I/51bcKEwQmWL._SL500_.jpg)

The next testing will probably be to make crystal and/or rauchmalt.

The next testing will probably be to make crystal and/or rauchmalt.