BrewinSoldier

Well-Known Member

- Joined

- Jul 13, 2015

- Messages

- 481

- Reaction score

- 53

has anyone used the trubtrapper in a grainfather? after my last batch w/ only 4 oz in it causing a blocked/slow circulation, i'm working on figuring out the best option for reducing trub. i measured it and it would fit, but the filter would probably be pushed up and the rim would be touching the heating element. thought about buying a hop basket filter but worried utilization would suffer. any other thoughts?

Haven't tried it yet but I just got my grainfather in.. I actually just bought a trubtrapper for my 3 tier setup but haven't brewed with it yet.. I plan on doing my first brew in my grainfather tomorrow with a very hoppy IPA.. I will be very upset if it clogs and causes me headaches. I did watch a YouTube video where some guy threw like 10 ounces of hops in his total and had no issues with clogging.

As far as hop spiders go, I have one for my 3 tier and have used it, as well as the bags and I can tell you there is a huge difference in utilization with both boil and dry hopping vs direct contact. I have done plenty of exbeeriments and it was the same everytime.. People always preferred the direct contact beers over the bagged/spidered in both taste and aroma.

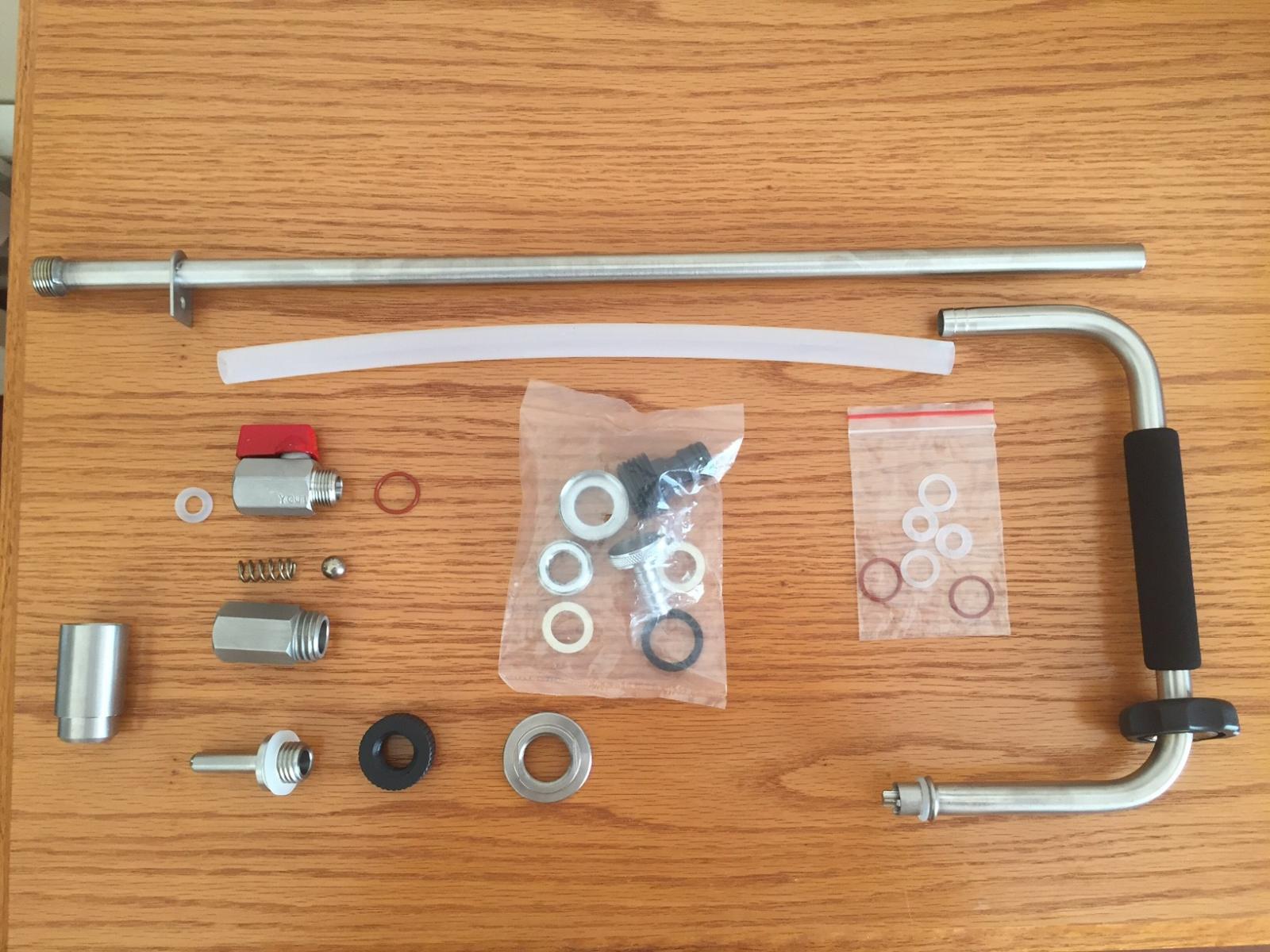

Snapped a pic for ya of the trubtrapper fitment in the grainfather.. It goes all the way to one edge and sits snuggly against the GF hop screen, but doesn't push it up.. I wouldn't worry about the trubtrapper sitting on the element as the silicone can handle up to 600 degrees, and with liquid being inside the GF, no way it would ever touch that.. I don't know how good the whirlpool would be with its postion, and I don't think it would help much as far as recirculation goes because it's more for trapping trub after a whirlpool, and wouldn't be really assisting covering the GF screen.. Might still be worth a try.. Anyways, here's the pic.

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)