You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

GFCI Tripping Help

- Thread starter Hokie_Brewer

- Start date

Help Support Homebrew Talk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Hokie_Brewer

Well-Known Member

That was my first thought as well - I unhooked the pump completely the first time I tripped the GFCI and tested again. Same issue

Hokie_Brewer

Well-Known Member

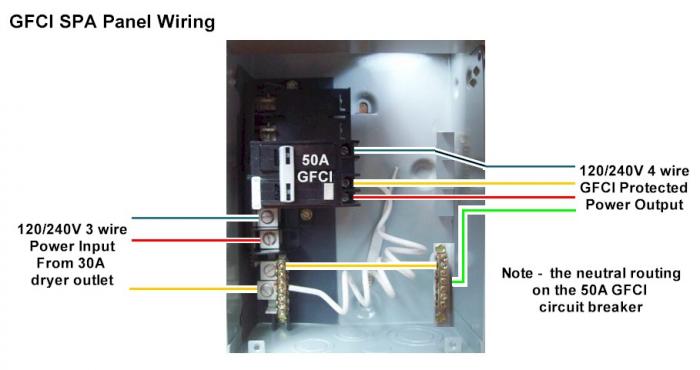

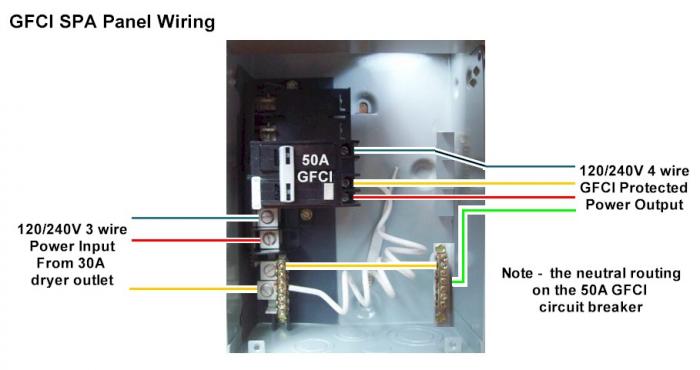

This is the spa panel wiring. I have an L14-30 receptacle mounted to the side of the spa panel enclosure. 3 wire dryer cord to the dryer receptacle

wbarber69

Well-Known Member

- Joined

- Oct 13, 2013

- Messages

- 2,191

- Reaction score

- 263

Yeah that's a nice diagram but can you show what yours actually looks like. I follow "electricians" around all the time that "know what they are doing." It might have passed his inspection. But he may not be looking at it as a whole.

Hokie_Brewer

Well-Known Member

$719.00

$799.00

EdgeStar KC2000TWIN Full Size Dual Tap Kegerator & Draft Beer Dispenser - Black

Amazon.com

$58.16

HUIZHUGS Brewing Equipment Keg Ball Lock Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging Brewing Equipment

xiangshuizhenzhanglingfengshop

$44.99

$49.95

Craft A Brew - Mead Making Kit – Reusable Make Your Own Mead Kit – Yields 1 Gallon of Mead

Craft a Brew

$7.79 ($7.79 / Count)

Craft A Brew - LalBrew Voss™ - Kveik Ale Yeast - For Craft Lagers - Ingredients for Home Brewing - Beer Making Supplies - (1 Pack)

Craft a Brew

$10.99 ($31.16 / Ounce)

Hornindal Kveik Yeast for Homebrewing - Mead, Cider, Wine, Beer - 10g Packet - Saccharomyces Cerevisiae - Sold by Shadowhive.com

Shadowhive

$176.97

1pc Commercial Keg Manifold 2" Tri Clamp,Ball Lock Tapping Head,Pressure Gauge/Adjustable PRV for Kegging,Fermentation Control

hanhanbaihuoxiaoshoudian

$33.99 ($17.00 / Count)

$41.99 ($21.00 / Count)

2 Pack 1 Gallon Large Fermentation Jars with 3 Airlocks and 2 SCREW Lids(100% Airtight Heavy Duty Lid w Silicone) - Wide Mouth Glass Jars w Scale Mark - Pickle Jars for Sauerkraut, Sourdough Starter

Qianfenie Direct

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

yunchengshiyanhuqucuichendianzishangwuyouxiangongsi

$20.94

$29.99

The Brew Your Own Big Book of Clone Recipes: Featuring 300 Homebrew Recipes from Your Favorite Breweries

Amazon.com

$53.24

1pc Hose Barb/MFL 1.5" Tri Clamp to Ball Lock Post Liquid Gas Homebrew Kegging Fermentation Parts Brewer Hardware SUS304(Liquid Hose Barb)

Guangshui Weilu You Trading Co., Ltd

$22.00 ($623.23 / Ounce)

AMZLMPKNTW Ball Lock Sample Faucet 30cm Reinforced Silicone Hose Secondary Fermentation Homebrew Kegging joyful

无为中南商贸有限公司

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)

$6.95 ($17.38 / Ounce)

$7.47 ($18.68 / Ounce)

Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]

Hobby Homebrew

Hokie_Brewer

Well-Known Member

wbarber69

Well-Known Member

- Joined

- Oct 13, 2013

- Messages

- 2,191

- Reaction score

- 263

I'm stumped everything looks right. I suppose the wiring comes in from a 30amp dryer plug since it's 3 pole. There could be issues on that side but that's the last place to check. I've never come across this type of element what brand is it so I can look at the specs.

Hokie_Brewer

Well-Known Member

honestly, i'm not sure. My electrician family friend had this element (which is a steam table element) form a job he was working on and i decided to use it. I liked the bottom mount because it provides a very solid seal on the flat bottom of my pot. This is the closest I came to finding the similar element:

http://www.lonestarrestaurantsupply.com/immersed-5000-watts-heating-element-208v

http://www.lonestarrestaurantsupply.com/immersed-5000-watts-heating-element-208v

Hokie_Brewer

Well-Known Member

Hokie_Brewer

Well-Known Member

wbarber69

Well-Known Member

- Joined

- Oct 13, 2013

- Messages

- 2,191

- Reaction score

- 263

In your configuration the 5000watt element becomes a 5300watt element. But the draw is still way less than 40amps so all that looks fine. As long as it's wired up in parallel like it looks like it is. I wonder what size wire is in the wall behind the dryer plug. If it can't handle the heat it could give the gfi some problems. But your still way under 30 amps so it shouldn't matter. Unless the element is faulty. Or something else. Perhaps it's something to do with the fact that when you achieve proper temperature the pid begins cycling the element and that is causing the trip. Could be a bad pid. But it would have to be really bad to make the whole thing trip like that.

Hokie_Brewer

Well-Known Member

I dont think it has to do with the PID, because I tried it with both automatic mode and manual mode (20% and 60% manual power) and had the same problem with any of those options.

Do you think it has anything to do with the coils being so close together on the actual element? The GFCI would trip as soon as bubbles started to appear between those coils

Do you think it has anything to do with the coils being so close together on the actual element? The GFCI would trip as soon as bubbles started to appear between those coils

wbarber69

Well-Known Member

- Joined

- Oct 13, 2013

- Messages

- 2,191

- Reaction score

- 263

You could bypass the ssr. Go contactor to element directly. And switch the element on. Let the pid think it's doing the work when it's not controlling the element at all. See if it gets up to boil and then see if it will trip. It will continue to get hotter and hotter so you'll have to determine when the test is over and shut it down. If it doesn't trip then it's either the ssr or pid causing the trip.

Hokie_Brewer

Well-Known Member

yeah, good idea. i will have to try that at some point this week

wbarber69

Well-Known Member

- Joined

- Oct 13, 2013

- Messages

- 2,191

- Reaction score

- 263

If it does trip then try again with the ssr dc contacts removed from the pid. And try again. If it still trips. Then disconnect the pid(No more temp reading so you might need to use a thermometer or watch for a boil.). If it still trips without the pid and ssr connected then it's got something to do with the element.

Hokie_Brewer

Well-Known Member

yep, sounds like a plan. i will get on that and post back later.

anyone else reading this conversation see something we missed??

anyone else reading this conversation see something we missed??

??? Vey puzzling indeed.

How about when it come to the high temp (about when the GFCI trips) some liquid might have leaked through the element mounting seals into the element connection chamber. It wouldn't take much water to give it a GFCI trip to ground path.

Ok... Ok... I'm grabbing at straws too. But maybe worth a check anyway.

P-J

How about when it come to the high temp (about when the GFCI trips) some liquid might have leaked through the element mounting seals into the element connection chamber. It wouldn't take much water to give it a GFCI trip to ground path.

Ok... Ok... I'm grabbing at straws too. But maybe worth a check anyway.

P-J

Hokie_Brewer

Well-Known Member

??? Vey puzzling indeed.

How about when it come to the high temp (about when the GFCI trips) some liquid might have leaked through the element mounting seals into the element connection chamber. It wouldn't take much water to give it a GFCI trip to ground path.

Ok... Ok... I'm grabbing at straws too. But maybe worth a check anyway.

P-J

Yes, i thought that as well. I checked after the first set of trips during my brew day and no moisture in the enclosure. Then i tested the next day with water, tripped the GFCI, and still no moisture...

Hokie_Brewer

Well-Known Member

I wonder if that element can handle the fast switching we normally use on the camcos and the like. It might be something as simple as adjusting the on/off timing in the pid. But who knows.

it's set to 2 seconds as of now - i can try to increase that as well

wbarber69

Well-Known Member

- Joined

- Oct 13, 2013

- Messages

- 2,191

- Reaction score

- 263

Since you say it only happens at boil it makes me think it's happening when the ssr goes from on all the time to suddenly switching on and off. And in duty cycle mode it's more of a pwm type of scenario. What your actually doing is switching on and off so fast that the times on as opposed to off determine the duty cycle 80% means it's on for 80% more cycles than its off. Where with an analog manual control you are actually determining the voltage by resistance so an 80% means that your passing 80% of your potential voltage.

But. The GFCI will only trip under 2 conditions:

When there is a power overload beyond the amp range of the breaker (this in not happening).

And when there is a milliamp leakage current from either hot OR the neutral to equipment ground.

When there is a power overload beyond the amp range of the breaker (this in not happening).

And when there is a milliamp leakage current from either hot OR the neutral to equipment ground.

Hokie_Brewer

Well-Known Member

Since you say it only happens at boil it makes me think it's happening when the ssr goes from on all the time to suddenly switching on and off. And in duty cycle mode it's more of a pwm type of scenario. What your actually doing is switching on and off so fast that the times on as opposed to off determine the duty cycle 80% means it's on for 80% more cycles than its off. Where with an analog manual control you are actually determining the voltage by resistance so an 80% means that your passing 80% of your potential voltage.

Can't be this. In manual mode at 60% it was cycling the same rate from 70 degs up to 200 deg just fine, then trips the breaker as it approaches boiling temp

Sent from my iPhone using Home Brew

Hokie_Brewer

Well-Known Member

But. The GFCI will only trip under 2 conditions:

When there is a power overload beyond the amp range of the breaker (this in not happening).

And when there is a milliamp leakage current from either hot OR the neutral to equipment ground.

So, any chance the element itself is leaking current to the pot (which is grounded) when the boil is starting?

wbarber69

Well-Known Member

- Joined

- Oct 13, 2013

- Messages

- 2,191

- Reaction score

- 263

But. The GFCI will only trip under 2 conditions:

When there is a power overload beyond the amp range of the breaker (this in not happening).

And when there is a milliamp leakage current from either hot OR the neutral to equipment ground.

It could under very certain circumstances happen if the spa panel is pulling more voltage over the dryer plug than can be sent back to earth. But I don't think that's the problem. There could be a short in the pid. Even though your not using the alarm function or the relays. It might be something internally that's grounding out. What is your alarms set to. If they are set to go off at 212 or close to it. Try setting them all the way up to 999. That will eliminate one more mechanical device that could be causing issues.

Similar threads

- Replies

- 37

- Views

- 3K

- Replies

- 20

- Views

- 931