Reached out to the Beersmith forum, as well...not to helpful yet.

Sorry to hear that.

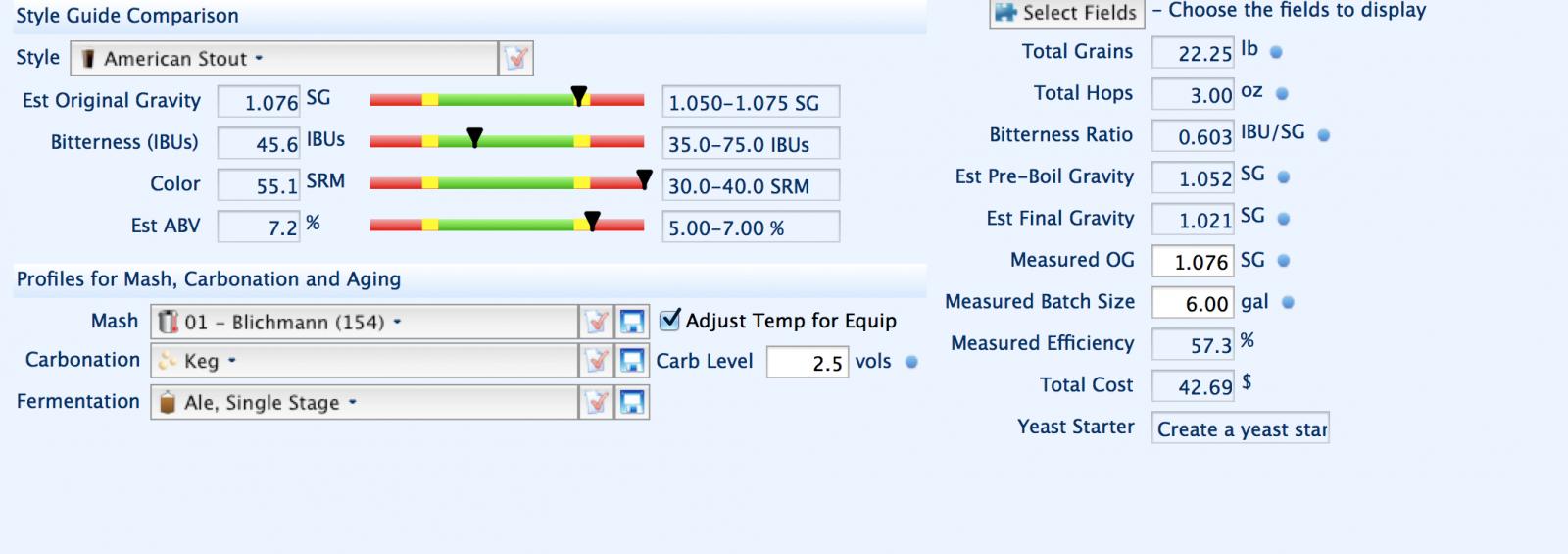

With BeerSmith, you set two parameters that everything else adjusts to create.

1) Your batch size. This is the amount you want in the fermenter.

2) Brewhouse Efficiency. This is the total percentage of all available sugars you want in the fermenter.

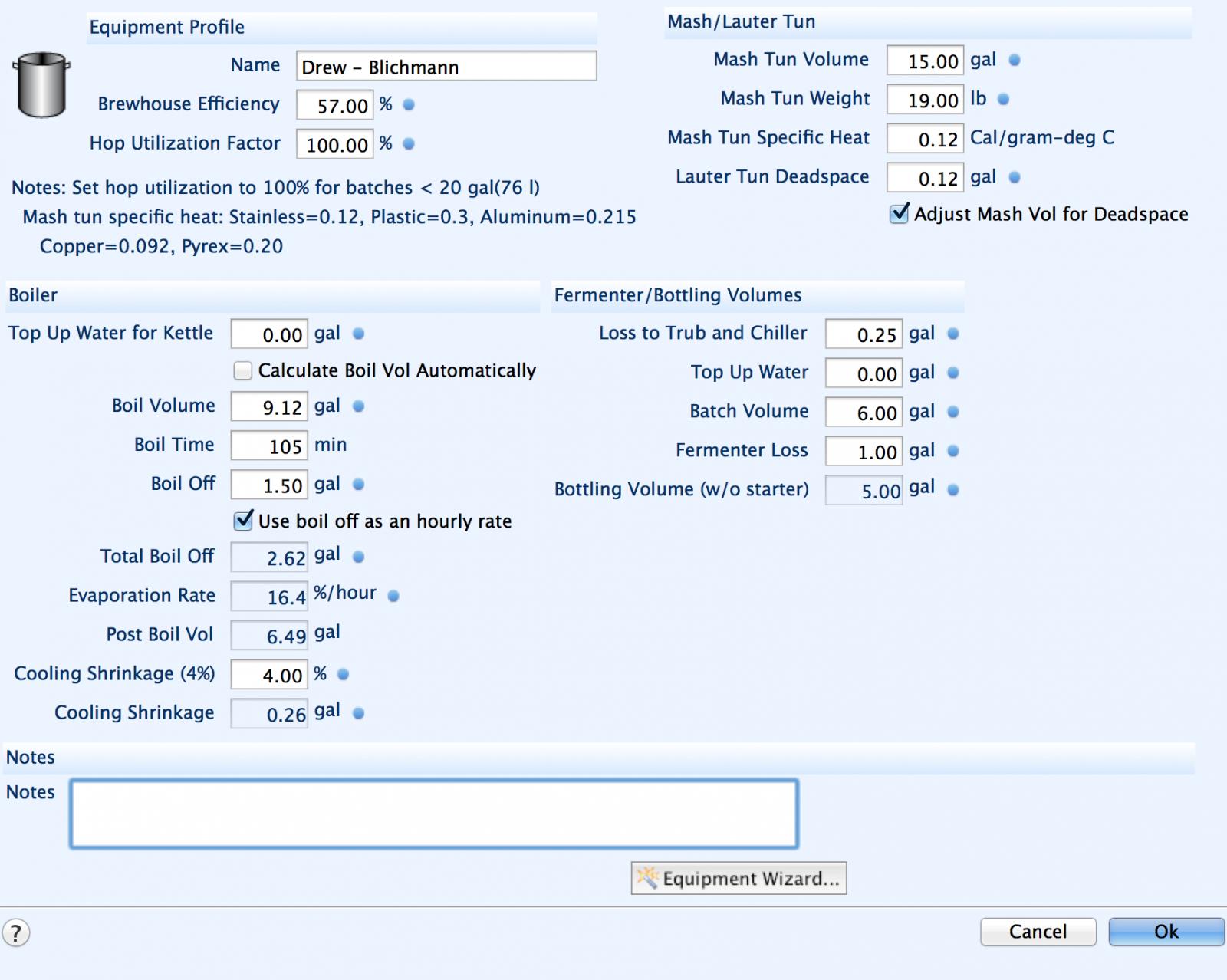

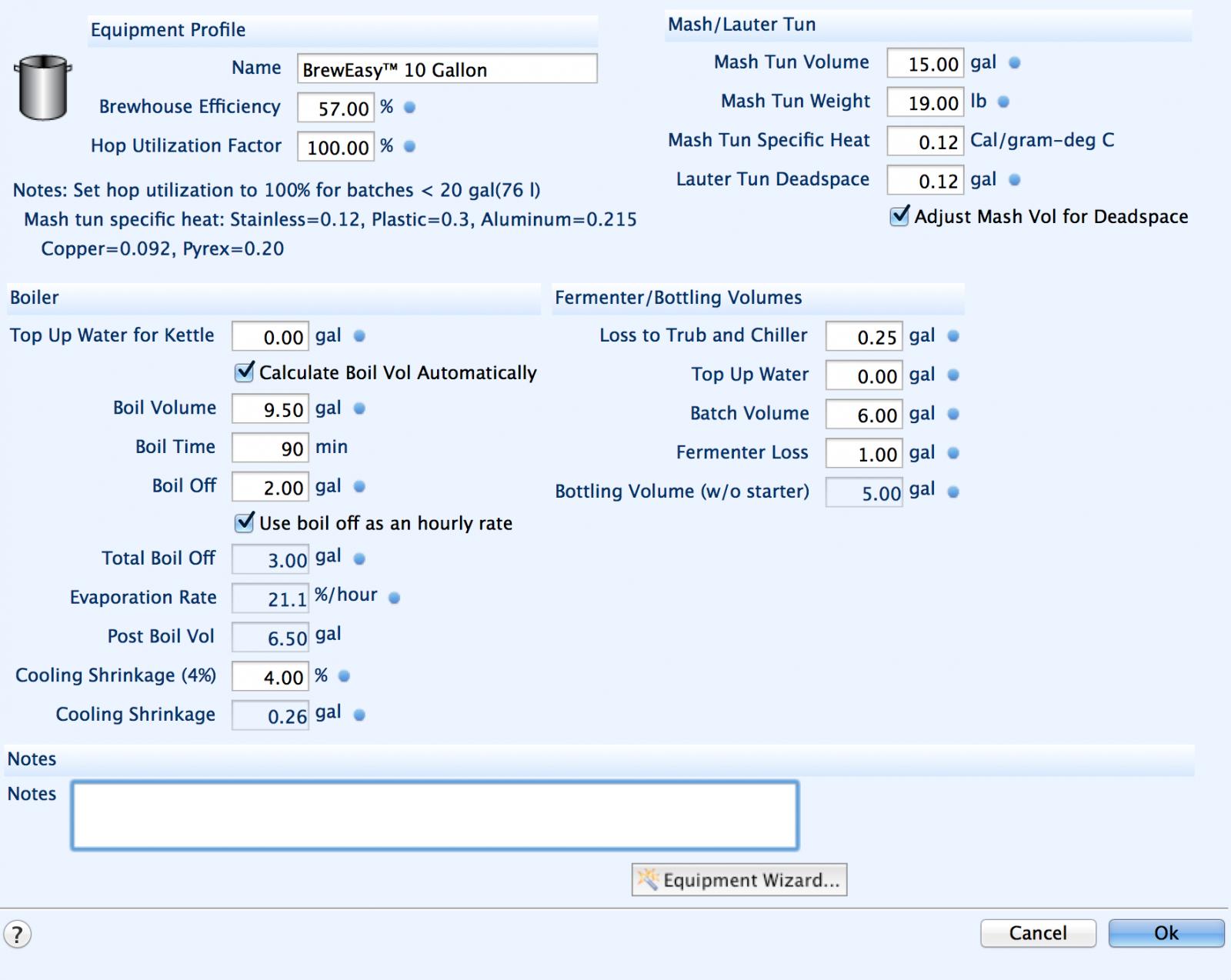

If you say you want 5.5 gallons, then all water amounts will adjust to yield that. If you know your kettle will only hold 7.5 gallons, and you want to boil longer, then the batch size must be reduced so that it doesn't overflow. If you notice in the Equipment profile, it doesn't even ask your kettle size, so in essence, it's telling you how big of a pot you need.

Brewhouse Efficiency is what gets everybody. BeerSmith calculates gravity based on this number.

If you input 75% BHE, then your saying that no matter what, you can get 75% of the available sugars into the fermenter. With Loss to Trub set to zero, it is the same as Mash efficiency. As soon as you add trub loss, you need additional sugar to cover the additional volume. Without increasing ingredients, the ONLY place this sugar can come from is higher mash efficiency, which is exactly what BeerSmith does.

The thing to do is to just subtract your trub percentage by the percentage of wort volume in the fermenter to get into the ballpark. Once you've brewed and measured gravity & volume along the way, you'll find the Measured Efficiency field in the Fermentation tab. Use this in your equipment profile as BHE.

Putting this together:

You have a recipe for 5.5 gallons. You know you get 70% mash efficiency and you have 0.5 gallons of trub left in the kettle.

Wort yield to the Fermenter = 91.6%

Mash Eff * Wort Yield = 0.7 * 0.916 = 64.12% BHE