mattyp1214

Well-Known Member

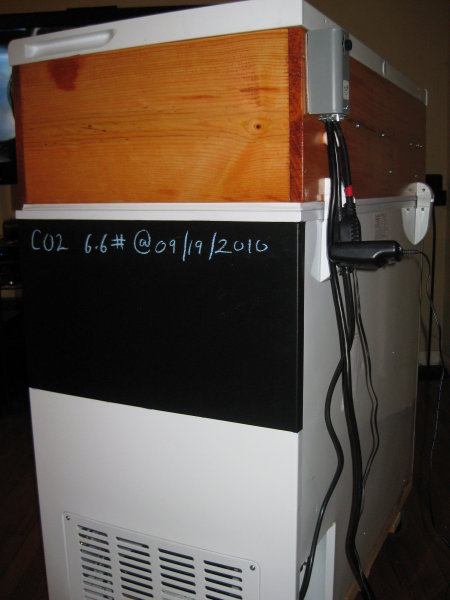

Bought red oak and red oak stain. Finally just ended up screwing it together after an unsuccessful attempt at gluing as well. Took a good hour to get all the holes lined up and exactly 1 3/4" from the edge. Looks great.

BUT I decided to take the lid off the freezer and line it up and see how it looked... for some reason it didn't sit on top of the lid right. So I measured it... well the obviously frustrated guy at HD who had to cut my $41 dollars worth of red oak had only cut it 36" after telling him repeatedly what I needed. I'm pretty pissed right now, drinking a home brew to get myself together before my GF takes me back so I can get my money back and go to lowes.....

BUT I decided to take the lid off the freezer and line it up and see how it looked... for some reason it didn't sit on top of the lid right. So I measured it... well the obviously frustrated guy at HD who had to cut my $41 dollars worth of red oak had only cut it 36" after telling him repeatedly what I needed. I'm pretty pissed right now, drinking a home brew to get myself together before my GF takes me back so I can get my money back and go to lowes.....

![Craft A Brew - Safale S-04 Dry Yeast - Fermentis - English Ale Dry Yeast - For English and American Ales and Hard Apple Ciders - Ingredients for Home Brewing - Beer Making Supplies - [1 Pack]](https://m.media-amazon.com/images/I/41fVGNh6JfL._SL500_.jpg)